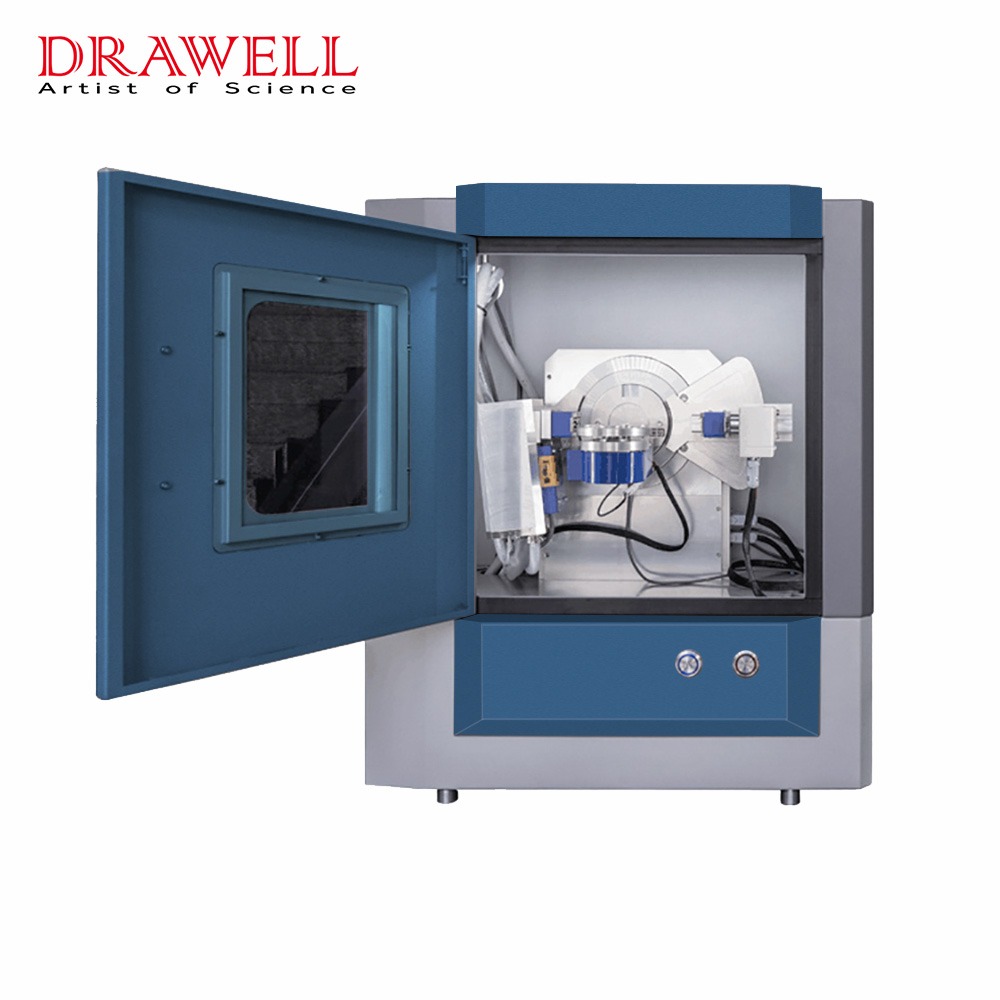

X-ray diffraction (XRD) is a powerful analytical technique widely used for characterizing the structure and composition of materials. However, the accuracy and reliability of XRD measurements heavily depend on the quality of sample preparation. In this article, we delve into the best practices for preparing samples of different forms for XRD analysis.

General Considerations for XRD Sample Preparation

Before discussing specific sample forms, it’s crucial to address some general considerations for XRD sample preparation, including:

- Homogeneity: Ensuring sample homogeneity is crucial to obtaining accurate XRD results. Inhomogeneous samples can lead to misleading diffraction patterns and erroneous conclusions. Proper grinding, mixing, and blending techniques should be employed to achieve uniformity throughout the sample.

- Minimizing Surface Effects: Surface effects, such as preferred orientation and surface roughness, can significantly impact XRD data. These effects can distort peak intensities and positions, leading to inaccuracies in phase identification and quantification. Surface smoothing techniques, such as polishing, can help minimize these effects and improve data quality.

- Avoiding Contamination: Contamination from external sources can introduce unwanted peaks and interfere with the analysis of the sample. It is essential to handle samples with clean equipment and in a controlled environment to prevent contamination. Additionally, proper cleaning procedures should be followed for equipment and tools used in sample preparation.

- Sample Handling Techniques: Proper handling of samples is critical to maintaining sample integrity throughout the preparation process. Care should be taken to avoid introducing mechanical stress or damage to the sample. Techniques such as gentle grinding, careful mounting, and secure storage should be employed to minimize sample degradation.

By addressing these general considerations, researchers can optimize the quality of their XRD samples and ensure the reliability of their XRD measurements.

Best Practices for XRD Sample Preparation in Different Forms

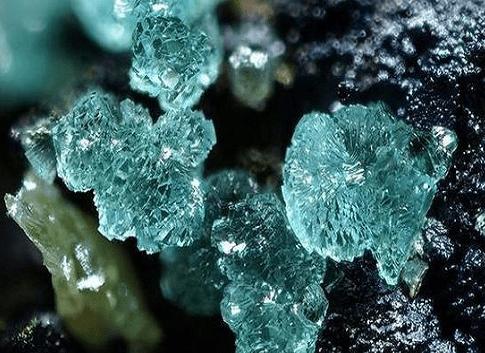

X-ray diffraction (XRD) is primarily used to analyze crystalline and semi-crystalline materials. Here are the main forms of samples that can be analyzed by XRD:

Powder XRD Sample Preparation

Best Practices for Powder XRD Sample Preparation:

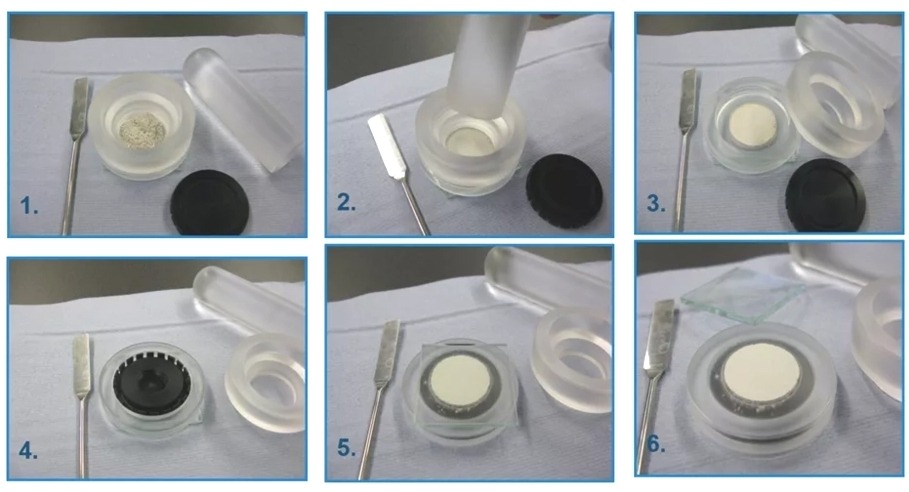

- Grinding and Crushing Techniques: The first step in preparing powder samples for XRD analysis is to grind and crush the material into a fine powder. This ensures homogeneity and allows for accurate diffraction measurements. Use a mortar and pestle or a ball mill to achieve a fine powder with particle sizes typically in the micrometer range.

- Homogenization Methods: Even after grinding, some samples may still exhibit non-uniformity. Employ homogenization techniques such as mixing, blending, or sieving to ensure uniform distribution of particles throughout the sample. This helps to minimize the effects of sample heterogeneity on XRD data.

- Mounting Procedures: Proper mounting of the powder sample is essential for reproducible XRD measurements. Transfer the homogenized powder onto a sample holder or mount using a suitable adhesive. Ensure that the sample is evenly distributed and packed to achieve good coverage of the holder surface without overloading.

- Surface Smoothing Techniques: Powder samples may exhibit surface irregularities or roughness that can affect XRD data quality. Consider using surface smoothing techniques such as tapping or gently compressing the powder surface to achieve a flat and uniform surface. Avoid excessive compaction, as this can induce preferred orientation effects.

- Backfilling: Backfilling is a technique used to minimize preferred orientation effects in powder samples. After mounting the powder sample, fill any gaps or voids on the sample holder surface with a low-absorbing material, such as glass or silicon powder. This helps to ensure an even distribution of X-ray scattering from the sample.

By following these best practices, researchers can optimize the quality of their powder XRD samples and obtain reliable and reproducible XRD data for material characterization.

Solid XRD Sample Preparation

Best Practices for Solid XRD Sample Preparation:

- Sectioning Techniques: For solid samples, particularly bulk materials or crystalline solids, sectioning is often necessary to obtain a flat and uniform surface for XRD analysis. Use precision cutting tools such as diamond saws or laser cutters to create smooth and parallel surfaces free from defects or damage.

- Surface Polishing Methods: After sectioning, the sample surfaces must be polished to remove any cutting artifacts, scratches, or surface roughness that could interfere with XRD measurements. Employ sequential polishing steps using progressively finer abrasives (e.g., diamond paste or alumina) until a mirror-like finish is achieved.

- Mounting Procedures: Mount the polished solid sample onto a suitable sample holder using an appropriate adhesive or mounting medium. Ensure that the sample is securely affixed to the holder and that the mounting process does not introduce additional stress or deformation to the sample surface.

- Surface Protection Techniques: To prevent sample damage during handling and analysis, consider applying a protective coating or film to the polished surface. This can help minimize oxidation, contamination, or surface degradation that could affect XRD data quality. Common protective coatings include thin layers of wax, polymer films, or inert gases.

- Calibration and Validation: Before conducting XRD analysis, it is essential to calibrate and validate the instrument parameters using certified reference materials. Perform alignment checks, instrument calibration, and resolution tests to ensure accurate and reliable XRD measurements. Regular maintenance and calibration of the XRD instrument are also critical to maintaining data quality over time.

By adhering to these best practices, researchers can prepare solid samples for XRD analysis with precision and accuracy, leading to reliable characterization of the sample’s crystal structure and properties.

Thin Film XRD Sample Preparation

Best Practices for Thin Film XRD Sample Preparation:

- Substrate Cleaning Procedures: Start by thoroughly cleaning the substrate surface to remove any contaminants or residues that could interfere with thin film deposition or XRD analysis. Use appropriate solvents, such as acetone or isopropyl alcohol, followed by rinsing with deionized water and drying with inert gas or nitrogen.

- Deposition Techniques: Choose an appropriate thin film deposition method based on the material and desired film properties. Common techniques include physical vapor deposition (PVD), chemical vapor deposition (CVD), sputtering, and spin coating. Optimize deposition parameters such as temperature, pressure, deposition rate, and film thickness to achieve the desired film quality and thickness.

- Thickness Measurement Methods: Accurate measurement of thin film thickness is essential for interpreting XRD data and understanding film properties. Utilize techniques such as ellipsometry, profilometry, or stylus profilometry to measure film thickness before XRD analysis. Calibration using reference samples with known thicknesses can improve measurement accuracy.

- Mounting and Handling Considerations: Handle thin film samples with care to avoid damage or contamination. Mount the thin film sample onto a suitable holder or substrate using non-destructive mounting techniques such as vacuum chucking or adhesive tape. Minimize handling and exposure to air to prevent oxidation or degradation of the thin film.

- Specialized Sample Environments: Consider using specialized sample environments or stages during XRD analysis to accommodate thin film samples. This may include low-background sample holders, heating or cooling stages, or in situ measurement chambers to study thin film behavior under specific conditions (e.g., temperature, pressure, or gas atmosphere).

By following these best practices, researchers can prepare thin film samples for XRD analysis with precision and reliability, enabling accurate characterization of thin film structure, composition, and properties.

Troubleshooting Common Sample Preparation Issues

Despite meticulous preparation, sample preparation issues may still arise. Common problems include contamination, sample inhomogeneity, surface irregularities, and damage. Identifying the root cause of these issues and implementing corrective measures can help mitigate these issues.

| Common Sample Preparation Issues | Troubleshooting Tips |

| Identification of Contaminants | Perform additional sample cleaning using appropriate solvents. |

| Consider acid or alkali treatments for stubborn contaminants. | |

| Verify sample purity using complementary analytical techniques such as SEM or EDS. | |

| Addressing Sample Inhomogeneity | Re-homogenize the sample using techniques like grinding, mixing, or blending. |

| Ensure thorough mixing of powders or homogenization of solid samples. | |

| Analyze multiple sample aliquots to verify homogeneity. | |

| Dealing with Surface Irregularities | Use finer polishing techniques to remove surface irregularities. |

| Apply protective coatings or films to minimize surface damage. | |

| Avoid excessive pressure or abrasive materials during polishing. | |

| Solutions for Sample Damage | Handle samples with care to minimize mechanical stress. |

| Optimize sample mounting procedures to ensure secure attachment. | |

| Consider using support materials or backfilling techniques for additional stability. | |

| Optimizing Instrument Parameters | Verify instrument alignment, calibration, and performance. |

| Optimize XRD parameters such as scan speed, range, and detector settings. | |

| Regularly monitor instrument performance and conduct maintenance as needed. |

By systematically addressing these common sample preparation issues, researchers can enhance the quality and reliability of XRD data, leading to more accurate characterization of materials and their properties.

Conclusion

Proper sample preparation is essential for obtaining reliable and accurate XRD data across various sample forms. By adhering to best practices and considering the unique characteristics of each sample type, researchers can ensure the quality of their XRD analysis. Addressing common sample preparation issues through troubleshooting techniques further enhances the robustness of XRD measurements. Ultimately, meticulous sample preparation lays the foundation for meaningful insights into the structural properties of materials using XRD analysis.