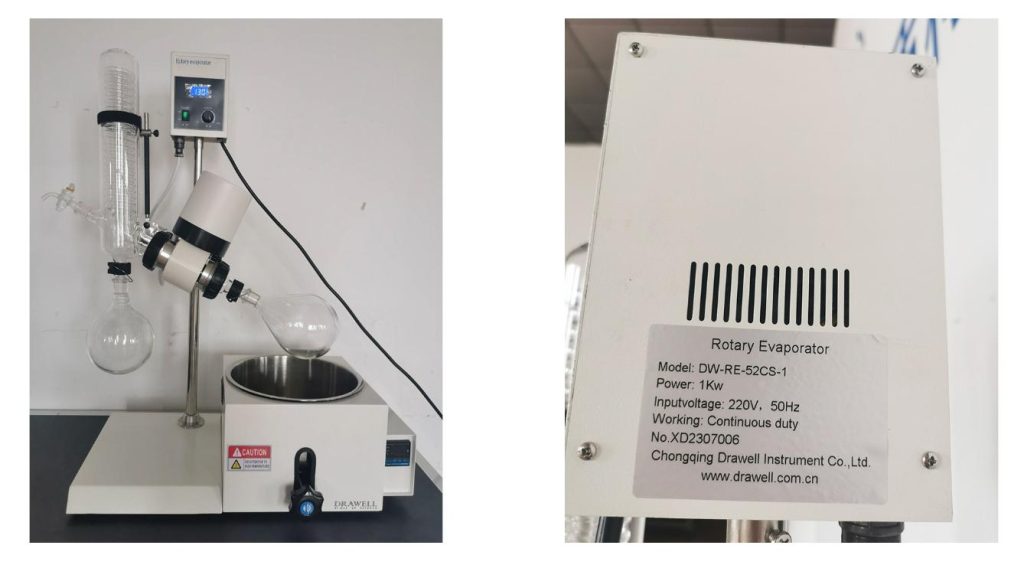

In many fields such as chemistry, pharmaceuticals, food science and materials science, precision extraction is a key step in sample preparation and purification. One of the most critical tools in achieving this level of precision is the rotary evaporator. This piece of equipment, often seen in laboratories, plays a pivotal role in refining extraction processes, ensuring that the final product is both pure and consistent. But what exactly makes rotary evaporators so essential for precision extraction? Let’s delve into the intricacies of why they are indispensable in modern extraction methods.

The Importance of Precision in Extraction

Extraction is the process of isolating specific compounds from a mixture, a technique fundamental in many industries, including pharmaceuticals, chemicals, and natural products. The success of an extraction process hinges on precision—achieving the desired compound in the highest purity and yield possible while minimizing impurities. Precision in extraction directly impacts the quality, efficacy, and safety of the final product. For instance, in the pharmaceutical industry, the active ingredients extracted must meet stringent purity standards to be effective and safe for use. In the food industry, flavors and aromas extracted must be consistent to ensure product uniformity.

Precision also affects efficiency; a more precise extraction process often leads to higher yields and reduced waste, which is crucial for cost-effectiveness and sustainability. Without precision, extraction processes could result in impure products, inconsistent results, and higher operational costs due to wasted materials and the need for repeated processing. This is where rotary evaporators come into play, offering unparalleled control over the critical variables in the extraction process.

How Rotary Evaporators Ensure Precision?

Rotary evaporators are designed to provide the precise control needed during the extraction process. Their ability to regulate temperature, rotation speed, and vacuum pressure makes them indispensable for achieving high-quality extracts. Here’s how they contribute to precision:

1. Temperature Control:

Maintaining the right temperature ensures that solvents evaporate efficiently without degrading the compounds of interest. Rotary evaporators are equipped with a water or oil bath that heats the solvent-containing flask. The temperature can be precisely adjusted to match the boiling point of the solvent under reduced pressure. This ensures that the solvent evaporates efficiently without exposing the sample to unnecessary heat, which could compromise its integrity.

Precision Benefits: By fine-tuning the bath temperature, rotary evaporators allow users to optimize the evaporation process for each specific solvent and sample, ensuring that the extraction is both efficient and gentle. This precise control prevents the breakdown of delicate compounds, maintaining the purity and potency of the extract.

2. Speed Control:

The rotation speed of the evaporation flask plays a crucial role in the efficiency and uniformity of the evaporation process. Proper control over this parameter ensures that the sample is evenly distributed across the inner surface of the flask, enhancing the rate of evaporation. The flask in a rotary evaporator rotates at adjustable speeds, which can be tailored to the specific viscosity and volume of the liquid inside. This rotation creates a thin film of the liquid on the flask’s inner surface, increasing the surface area for evaporation and improving heat transfer.

Precision Benefits: By adjusting the rotation speed, users can prevent issues such as bumping or splashing, which can lead to sample loss or contamination. The ability to control the speed ensures that the evaporation process is consistent, leading to uniform results across different batches, which is especially important in industrial settings where reproducibility is key.

3. Vacuum Control:

Controlling the pressure inside the rotary evaporator system is essential for lowering the boiling point of solvents, allowing them to evaporate at much lower temperatures. This is particularly important for preserving the integrity of volatile or thermally sensitive compounds. Rotary evaporators are equipped with vacuum pumps that reduce the pressure within the system, effectively lowering the boiling point of the solvent. The vacuum level can be precisely adjusted to match the specific requirements of the extraction process, allowing for efficient evaporation without excessive heating.

Precision Benefits: The ability to precisely control the vacuum level allows users to tailor the evaporation conditions to the specific solvent and sample being processed. This reduces the risk of thermal degradation and ensures that even the most sensitive compounds are extracted with their properties intact. Moreover, the precise control over vacuum pressure enables more efficient solvent removal, which is crucial for high-purity extractions.

4. Solvent Recovery:

Efficient solvent recovery is a critical aspect of the extraction process, both for environmental sustainability and cost-effectiveness. Rotary evaporators are designed to maximize solvent recovery while maintaining the purity of the extract. As the solvent evaporates, it is condensed in a cooling coil and collected in a receiving flask. Rotary evaporators are equipped with condensers that can be precisely controlled to optimize the condensation of the solvent vapor back into liquid form.

Precision Benefits: By fine-tuning the condensation process, rotary evaporators ensure that nearly all of the solvent can be reclaimed for reuse, reducing waste and lowering operational costs. This also minimizes the environmental impact of the extraction process. Additionally, precise solvent recovery ensures that the extract remains free from residual solvents, which is crucial for meeting quality and safety standards, particularly in the pharmaceutical and food industries.

In a word, rotary evaporators provide unparalleled precision in the extraction process by allowing meticulous control over temperature, rotation speed, vacuum pressure, and solvent recovery. These capabilities ensure that the extracted compounds are of the highest possible purity and quality, making rotary evaporators indispensable tools for any application requiring exacting standards.

Applications of Rotary Evaporators in Precision Extraction

Rotary evaporators are versatile tools used across various industries for precise extraction processes. Here are some of their key applications:

- Pharmaceutical Industry: In drug development and manufacturing, rotary evaporators are essential for extracting active pharmaceutical ingredients (APIs) with high purity. They are used to remove solvents from reaction mixtures, concentrate active compounds, and purify intermediates, ensuring that the final product meets rigorous quality standards.

- Food and Beverage Industry: Rotary evaporators play a crucial role in flavor and aroma extraction. They are used to concentrate essential oils, extracts, and flavor compounds while preserving their delicate profiles. This precision ensures that the final product, whether it’s a beverage, seasoning, or fragrance, is consistent in taste and aroma.

- Chemical Industry: In chemical synthesis and formulation, rotary evaporators are used to isolate and purify compounds. Their ability to precisely control evaporation conditions makes them ideal for removing solvents and concentrating solutions, which is critical in producing high-quality chemicals for industrial applications.

In each of these industries, rotary evaporators are valued not just for their ability to perform extractions but for doing so with a level of precision that ensures the highest quality of the final product. Whether isolating active ingredients in pharmaceuticals, preserving delicate flavors in food, or ensuring the purity of chemicals, rotary evaporators are essential tools that help meet the rigorous standards of modern manufacturing and research.

Choosing the Right Rotary Evaporator for Precision Extraction

Precision in extraction is the cornerstone of quality in many industries, and rotary evaporators are at the heart of achieving this precision. Selecting the appropriate rotary evaporator is crucial for optimizing your extraction process. Several factors need to be considered:

- Size and Capacity: The size of the rotary evaporator should match the scale of your operations. Laboratory-scale rotary evaporators are suitable for small batches, while industrial-scale models are necessary for large-scale production. Choosing the right capacity ensures that the equipment can handle your extraction needs efficiently.

- Specific Application Needs: Different applications may require specific features in a rotary evaporator. For instance, if you are working with highly volatile solvents, a model with advanced vacuum control might be necessary. Understanding your specific extraction requirements will help you choose a rotary evaporator with the right features.

- Quality and Reliability: Investing in a high-quality rotary evaporator from a reputable manufacturer is essential for long-term reliability and performance. Durable construction, precision engineering, and robust components ensure that the equipment can withstand rigorous use and maintain accuracy over time.

If you are not sure to choose the type of rotary evaporator, we are here to help you, feel free to tell us your needs.