Miniaturized Near-Infrared spectrometers represent a significant leap in analytical technology, offering powerful performance in a compact size. These devices operate in the near-infrared region (typically 800–2500nm), enabling them to detect molecular vibrations and provide detailed information about the chemical composition of various materials. Their portability and reduced size make them ideal for real-time, on-site applications across industries such as agriculture, pharmaceuticals, food processing, and environmental monitoring.

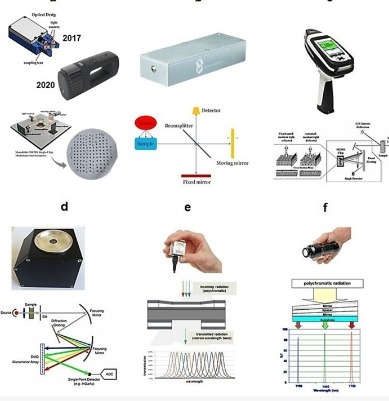

The Evolution of Miniaturized Near-Infrared Spectrometers

This chart outlines the progression of miniaturized Near-Infrared(NIR) spectrometers, emphasizing key advancements and their growing application across industries.

| Era | Technological Advances | Key Improvements | Applications |

| Early 2000s | Initial development of compact NIR components | Limited portability; large form factor; basic performance | Research laboratories, pharmaceuticals |

| Mid-2000s | Introduction of microelectromechanical systems (MEMS) in Near-Infrared equipment | Improved portability; enhanced resolution and sensitivity | Food analysis, pharmaceutical testing, academic research |

| 2010s | Integration of fiber optics and advanced light sources | Greater wavelength range; more precise spectral data | Field analysis, environmental monitoring, and industrial QC |

| Late 2010s | Development of low-cost sensors and handheld devices | Affordability increases; user-friendly interfaces introduced | Agriculture, food processing, quality control in manufacturing |

| 2020s & Beyond | AI-enhanced NIR spectrometry, smartphone integration, IoT connectivity | Real-time data analysis; cloud integration; miniaturization | Smart agriculture, remote sensing, consumer electronics |

Key Features and Advantages of Miniaturized Near-Infrared Spectrometers

- Portability: Compact and lightweight, miniaturized Near-Infrared spectrometers are ideal for handheld use and field applications, allowing for easy on-site analysis.

- Real-time Analysis: They provide immediate feedback on the chemical composition of materials, facilitating faster decision-making in industries like agriculture, pharmaceuticals, and food processing.

- Cost Efficiency: These type of NIR spectrometers are more affordable due to advances in manufacturing, making them accessible to a wider range of industries and research applications.

- Non-invasive Testing: Miniaturized Near-Infrared spectrometers perform non-destructive analysis, preserving samples and allowing for repeated measurements without damage.

- Energy Efficiency: With lower power consumption compared to larger instruments, they are well-suited for portable use, especially in battery-powered devices.

- Versatility: These spectrometers can analyze a wide variety of materials, including solids, liquids, and gases, making them useful across multiple sectors.

- Improved Accuracy and Sensitivity: Despite their small size, miniaturized NIR spectrometers maintain high levels of accuracy and sensitivity in detecting molecular structures and compositions.

These features make miniaturized NIR spectrometers highly valuable in diverse industries for rapid, efficient, and precise chemical analysis.

Applications of Miniaturized Near-Infrared Spectrometer

This chart highlights how miniaturized Near-Infrared spectrometers play a vital role in diverse industries for real-time quality control, monitoring, and analysis.

| Application Area | Industry | Purpose |

| Pharmaceutical Analysis | Pharmaceuticals | Real-time quality control of raw materials, tablets, and finished products |

| Agriculture & Food | Agriculture/Food Processing | Monitoring crop health, moisture content, and food composition during production |

| Environmental Monitoring | Environmental Science | Detecting pollutants, measuring water quality, and monitoring air emissions |

| Chemical Analysis | Chemical Manufacturing | Identifying chemical compounds, and monitoring reactions in production processes |

| Polymer & Plastic Industry | Plastics & Polymers | Measuring polymer composition and monitoring plastic processing quality |

| Medical Diagnostics | Healthcare | Non-invasive glucose monitoring, tissue analysis, and real-time medical diagnostics |

| Textiles | Textiles & Fabrics | Monitoring fiber properties and quality during textile production |

| Petrochemical Analysis | Oil & Gas | Analyzing hydrocarbons and detecting impurities in fuel and oil |

| Cosmetics & Personal Care | Cosmetics | Ensuring consistency and quality of ingredients in personal care products |

Key Trends of Miniaturized Near-Infrared Spectrometers

The future of miniaturized Near-Infrared spectrometers looks promising, with ongoing advancements likely to make them even more indispensable across a range of industries.

1. Enhanced Portability and Miniaturization

- Further size reduction: Continued improvements in sensor technology, microelectronics, and optical components will result in even smaller devices. This could lead to handheld or wearable spectrometers for personal use, enabling real-time analysis in remote locations.

- Increased integration: NIR spectrometers may be embedded directly into smartphones or other portable devices, making them more accessible for everyday applications, such as food safety, health monitoring, or environmental testing.

2. Artificial Intelligence and Machine Learning

- Improved data analysis: Integration with AI and machine learning will enhance the accuracy and speed of data interpretation. Advanced algorithms will allow for real-time, automatic processing of complex spectra, identifying materials or compounds more efficiently.

- Predictive analytics: AI will enable predictive models to be built from Near-Infrared data, helping industries anticipate changes or quality variations in production processes before they occur.

3. Broader Industrial Applications

- Expansion into new sectors: Miniaturized Near-Infrared spectrometers will likely find applications in emerging industries, including biotechnology, renewable energy, and personalized healthcare. For example, in biotech, Near-Infrared can monitor fermentation processes, while in healthcare, it could enable continuous monitoring of vital signs through non-invasive sensors.

- Inline automation: As manufacturing processes become more automated, miniaturized NIR spectrometers will be increasingly integrated into production lines for continuous, real-time quality control.

4. Lower Costs and Increased Accessibility

- Mass adoption: As the technology matures, the cost of producing miniaturized NIR spectrometers will continue to decrease, making them more affordable for small businesses and individual consumers. This could democratize access to high-quality spectral analysis, particularly in agriculture, pharmaceuticals, and consumer goods industries.

- Open-source platforms: The development of open-source software and tools for Near-Infrared spectroscopy could further lower the barrier to entry, encouraging widespread use in research, education, and small-scale industrial applications

5. Improved Spectral Range and Sensitivity

- Broader spectral coverage: Future miniaturized NIR spectrometers may cover a wider spectral range, enabling the detection of more substances and more detailed analysis. Enhanced sensitivity will allow for the identification of lower concentrations of compounds, expanding the scope of applications in fields like environmental monitoring and food safety.

- Higher precision: Advances in optics and sensor technology will improve the precision of miniaturized Near-Infrared spectrometers, making them more reliable for critical tasks like pharmaceutical quality control and medical diagnostics.

6. Sustainability and Environmental Impact

- Eco-friendly materials: Future designs could prioritize the use of sustainable materials and energy-efficient components, reducing the environmental impact of spectrometer production and operation.

- Sustainable agriculture: In precision farming, Near-Infrared spectrometers will continue to play a key role in monitoring crop health, soil quality, and water usage, contributing to more sustainable agricultural practices.

7. Interconnectivity and IoT Integration

- IoT integration: Miniaturized NIR spectrometers will likely be connected to the Internet of Things (IoT), allowing real-time data to be transmitted and analyzed remotely. This will enable faster decision-making and more effective monitoring of processes in industries like manufacturing, agriculture, and logistics.

- Cloud-based platforms: Data collected by Near-Infrared spectrometers can be uploaded to cloud platforms for centralized analysis, comparison, and storage, allowing industries to monitor trends and optimize processes on a global scale.

To sum up, the portability, cost efficiency and wide range of applications make Miniaturized Near-Infrared spectrometers become invaluable tools for quality control, environmental monitoring, and research. As technology continues to advance, NIR spectrometers are poised to become even more integral to the future of real-time spectroscopic analysis.