The allure of a luxurious cosmetic product lies not just in its ingredients but in its flawless texture, consistent quality, and lasting stability. To achieve this, cosmetic labs rely on advanced technologies that ensure uniformity and stability in their formulations. One such indispensable tool is the homogenizer for cosmetic. Here we delves into why homogenizers are absolutely essential in modern cosmetic laboratories, exploring their benefits, and applications.

What is Homogenization and Particle Size?

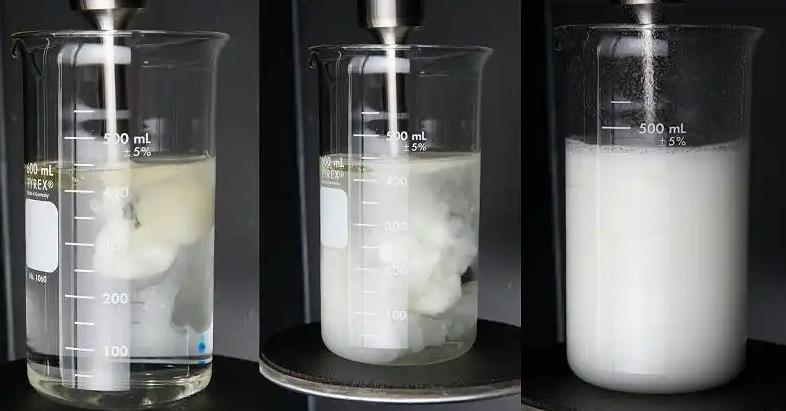

Homogenization is a process used to create a uniform mixture by breaking down particles or droplets into smaller, evenly distributed sizes. This is achieved by applying mechanical force, high pressure, or ultrasonic waves, depending on the method used.

Why is Particle Size Important in Cosmetics?

Particle size is a critical factor that directly influences the texture, stability, efficacy, and aesthetic appeal of cosmetic products. In cosmetic formulations, ingredients often exist as dispersed phases within a continuous phase, forming emulsions or suspensions. The size of these dispersed particles dictates how the product interacts with the skin and how it maintains its integrity over time. Smaller, uniform particles result in smoother, more consistent textures, enhancing the sensory experience for the user. Conversely, larger, uneven particles can lead to gritty textures, poor absorption, and phase separation, compromising product quality.

- Impact on Stability:

In emulsions, smaller droplets resist creaming and coalescence, preventing separation and extending shelf life. For example, in sunscreen formulations, micronized or nano-sized zinc oxide or titanium dioxide particles provide even UV protection and reduce the white cast associated with larger particles. However, there has been research showing potential issues that occur with the interaction between zinc oxide, and other sunscreen ingredients, so careful homogenizing is required.

- Enhanced Absorption:

Smaller particles can penetrate the skin more effectively, allowing active ingredients to reach their target sites. This is particularly crucial in serums and anti-aging products, where deep delivery of potent ingredients is desired.

- Improved Texture:

Homogenization creates a smooth, luxurious feel, enhancing consumer satisfaction. Even distribution of pigments in makeup formulations ensures flawless coverage and application.

The importance of controling the particule size, and maintaining the uniformity of the product is critical for cosmetic product satisfaction. The homogenizer provides the tools for that control.

Applications of Homogenizers in Cosmetic Formulations

The versatility of the homogenizer makes it an indispensable tool across a wide range of cosmetic applications. The key applications including:

Creating Stable Emulsions

Homogenizers are essential for mixing immiscible liquids, such as oil and water, to create stable emulsions. These emulsions form the foundation of many cosmetics, including moisturizers, sunscreens, and foundations.

Dispersing Pigments in Makeup

Products like foundations and lipsticks require even dispersion of pigments to achieve uniform color and texture. Homogenizers ensure that pigments are finely ground and evenly distributed, preventing clumping or streaking.

Incorporating Active Ingredients

Active ingredients, such as retinol or hyaluronic acid, must be uniformly distributed to ensure consistent efficacy across the product. Homogenizers prevent localized concentrations, enhancing product performance and safety.

Improving Viscous Products

Homogenizers excel in processing high-viscosity formulations like balms, gels, and hair masks, ensuring smooth textures and stable consistencies.

From creating lightweight serums to thick creams, homogenizers are versatile tools that enhance the quality of cosmetic formulations, catering to diverse product categories and consumer preferences.

Benefits of Homogenizers in Cosmetic Labs

The advantages of using homogenizers in cosmetic labs extend far beyond simply creating smooth textures.

- Consistency and Quality: Homogenizers ensure that every batch of product is identical in texture, color, and performance. This consistency is crucial for building brand reputation and meeting customer expectations.

- Enhanced Stability: Homogenization reduces the likelihood of phase separation or ingredient settling, extending the shelf life of cosmetic products. This is particularly important for products stored over long periods or exposed to varying environmental conditions.

- Improved Efficiency: Modern homogenizers are designed for high throughput, reducing production time and increasing operational efficiency. For example, a high-pressure homogenizer can process large batches in a fraction of the time required by traditional methods.

- Cost-Effectiveness: By ensuring efficient use of raw materials and minimizing waste, homogenizers lower production costs. They also reduce the need for post-processing corrections, such as re-mixing or stabilizing failed batches.

Ultimately, by optimizing product stability, texture, and efficacy, the homogenizers contribute to higher consumer satisfaction and brand loyalty.

Types of Homogenizers Best Suited for Cosmetic Labs

Cosmetic labs utilize various types of homogenizers, each with specific strengths and applications.

Drawell Homogenizers

These are ideal for creating fine emulsions and dispersions. They force liquids through a narrow gap at high pressure, breaking down particles to sub-micron sizes. This is particularly useful for lightweight serums and nano-emulsions.

Rotor-Stator Homogenizers

Commonly used for medium-to-high viscosity products, rotor-stator homogenizers create high shear forces to mix and emulsify ingredients effectively. They are ideal for creams, gels, and pastes.

Using high-frequency sound waves, ultrasonic homogenizers create cavitation, breaking particles into nano-sizes. These are perfect for delicate formulations requiring minimal heat, such as serums and sensitive skin products.

Vacuum Homogenizers

These combine homogenization with deaeration, removing trapped air to create smooth, air-free textures. They are crucial for products like anti-aging creams and balms that require stability and aesthetic appeal.

Selecting the right homogenizer depends on the product type, desired particle size, and production scale.

From small-scale formulations to large-scale production, the versatility and efficiency of homogenizers make them indispensable in cosmetic labs. Investing in the right homogenizer not only improves production processes but also ensures customer satisfaction and brand loyalty, solidifying their role in the future of cosmetic innovation. If you are looking for a homogenizer supplier, please feel free to contact Drawell.