Melting point determination is a critical aspect of material analysis, particularly in industries where understanding the thermal behavior of substances is essential. While traditional melting point measurements can handle standard materials, more complex samples often present unique challenges that require advanced technology. Automatic melting point meters are specifically designed to address these challenges, offering precise, efficient, and reliable analysis for complex samples.

Challenges in Measuring Melting Points of Complex Samples

This chart provides an overview of the common difficulties in measuring the melting points of complex samples and highlights the need for advanced measurement tools.

| Challenge | Description |

| Broad Melting Range | Complex mixtures often melt over a range of temperatures due to multiple components, making exact determination difficult. |

| Polymorphism | Substances with multiple crystalline forms exhibit different melting points, complicating the analysis. |

| Impurities | The presence of impurities can lower or broaden the melting point, obscuring the true melting behavior. |

| Small Sample Size | Limited quantities of complex samples make it harder to achieve precise measurements. |

| Phase Transitions | Complex samples may experience multiple phase transitions, requiring careful observation to capture all transitions. |

| Subjective Manual Observation | Manual methods are prone to human error and subjectivity, making consistent results difficult to achieve. |

| Inconsistent Heating Rates | Inaccurate or fluctuating heating rates can result in unreliable melting point data for complex materials. |

| High Sensitivity to Environment | Complex samples can be sensitive to environmental factors like humidity and pressure, affecting melting behavior. |

How Automatic Melting Point Meters Address These Challenges

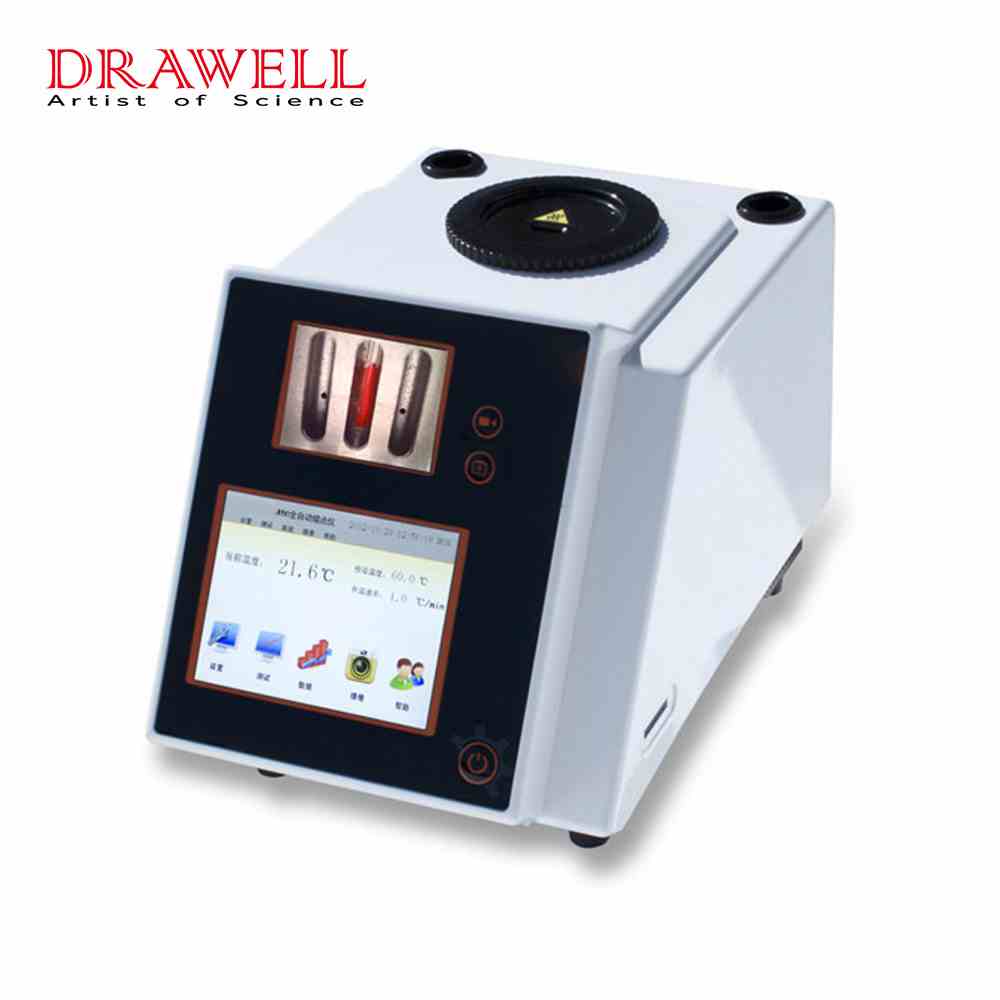

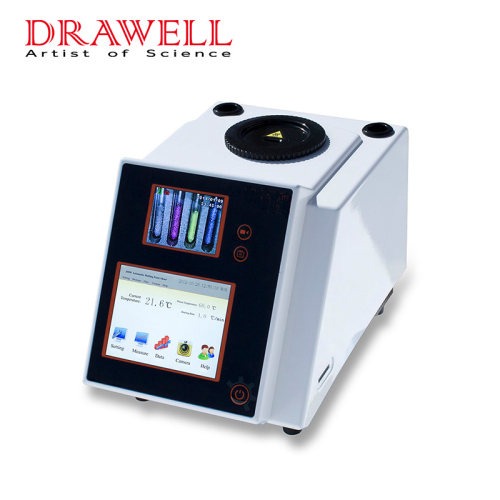

Automatic melting point meters are equipped with advanced features that make them ideal for handling the unique characteristics of complex samples.

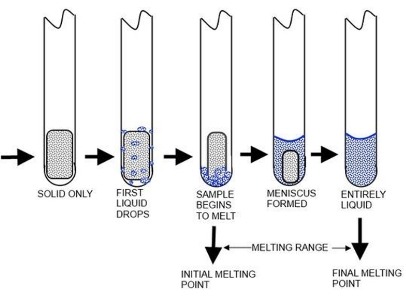

1. Precision Heating for Broad Melting Ranges

Automatic melting point meters offer highly controlled and precise heating rates, allowing users to carefully regulate the temperature increase. This ensures that even small differences in melting points are detected, and the full melting range of a sample is accurately recorded.

2. Digital Video Recording for Polymorphism

Automatic melting point meters are equipped with high-resolution digital video recording systems. These systems visually capture the entire melting process in real-time, allowing users to detect each phase transition. This is particularly important for distinguishing between different polymorphs or identifying any phase changes that occur during heating.

3. Automated Data Analysis to Reduce Human Error

Automatic melting point meters come with built-in software that automatically analyzes the melting process. The system precisely detects the point at which the sample melts and provides accurate data without the need for human judgment, ensuring more reliable and repeatable results for complex samples.

4. Multiple Sample Handling for Improved Throughput

Automatic melting point apparatus is designed to handle multiple samples simultaneously, improving throughput and efficiency. Each sample’s melting behavior is recorded and analyzed individually, even when multiple samples are tested at the same time, saving both time and resources in busy laboratory environments.

5. Detection of Impurities

Automated melting point meters are sensitive to subtle variations in the melting process. They can detect small deviations in the melting profile, indicating the presence of impurities. This feature allows users to better understand the purity and composition of complex samples, improving quality control and material analysis.

6. Customizable Heating Rates for Diverse Sample Types

Melting point apparatus allows users to customize heating rates automatically based on the specific properties of the sample being tested. Slow heating rates can be applied for samples with narrow melting ranges or those with subtle transitions, while faster rates can be used for samples with more straightforward melting behaviors. This flexibility ensures that each sample type is tested under optimal conditions.

7. Integrated Data Management for Comprehensive Analysis

Melting point meters often include integrated intelligent data logging and management systems that automatically record, store, and organize test data. This not only streamlines the analysis process but also makes it easier to track and compare results from multiple tests, ensuring a comprehensive understanding of complex sample behavior.

8. Enhanced Resolution for Small Samples

Melting point meters are high-resolution measurement system. They provides accurate readings for small sample sizes, which is particularly important when dealing with precious or limited materials. The high resolution ensures that even tiny samples can be analyzed with precision.

Applications in Key Industries of Automatic Melting Point Meters

This chart highlights how automatic melting point meters are applied across various industries for critical quality control, formulation, and research purposes.

| Industry | Applications | Key Uses |

| Pharmaceutical | Drug formulation, polymorphism studies, quality control | Determining the purity of drugs, studying polymorphic forms, ensuring consistent product quality |

| Chemical | Synthesis of chemicals, purity analysis, formulation development | Monitoring melting behavior of complex chemical compounds, ensuring consistency in chemical processes |

| Food & Beverage | Analysis of fats, oils, and other ingredients; quality control | Determining the melting points of fats, ensuring product consistency, verifying ingredient properties |

| Cosmetics | Formulation of creams, waxes, and other skincare products | Ensuring consistent texture and stability by measuring the melting points of ingredients like waxes |

| Plastics & Polymers | Polymer formulation, quality testing of plastics and resins | Monitoring melting points of polymers for material strength, consistency, and stability |

| Petrochemical | Analysis of petroleum products, waxes, and fuel components | Determining melting points of petrochemical products to ensure proper performance and refining processes |

| Academia & Research | Material science research, thermal behavior studies, compound analysis | Studying melting points of novel compounds, exploring thermal properties in research experiments |

| Environmental Testing | Analysis of pollutants, waste management | Determining the thermal behavior of contaminants, helping in the classification and management of waste |

Overall, automatic melting point meters are invaluable tools for laboratories dealing with complex samples. Their ability to precisely measure melting points, detecting impurities and handle multiple samples simultaneously makes them essential for industries where accurate thermal analysis is critical. Through automating the process, the melting point meters reduce human error, increasing efficiency in even the most challenging applications.