In today’s demanding healthcare, pharmaceutical, and research environments, sterilization is paramount. The fully automatic vertical autoclave is a device that can use high-temperature and high-pressure steam to efficiently sterilize various items. The emergence of this sterilizer has greatly improved the efficiency and accuracy of sterilization, ensuring medical safety and the accuracy of experimental results. But what exactly makes these autoclaves so dependable? Let’s look and see.

Consists of Fully Automatic Vertical Autoclave

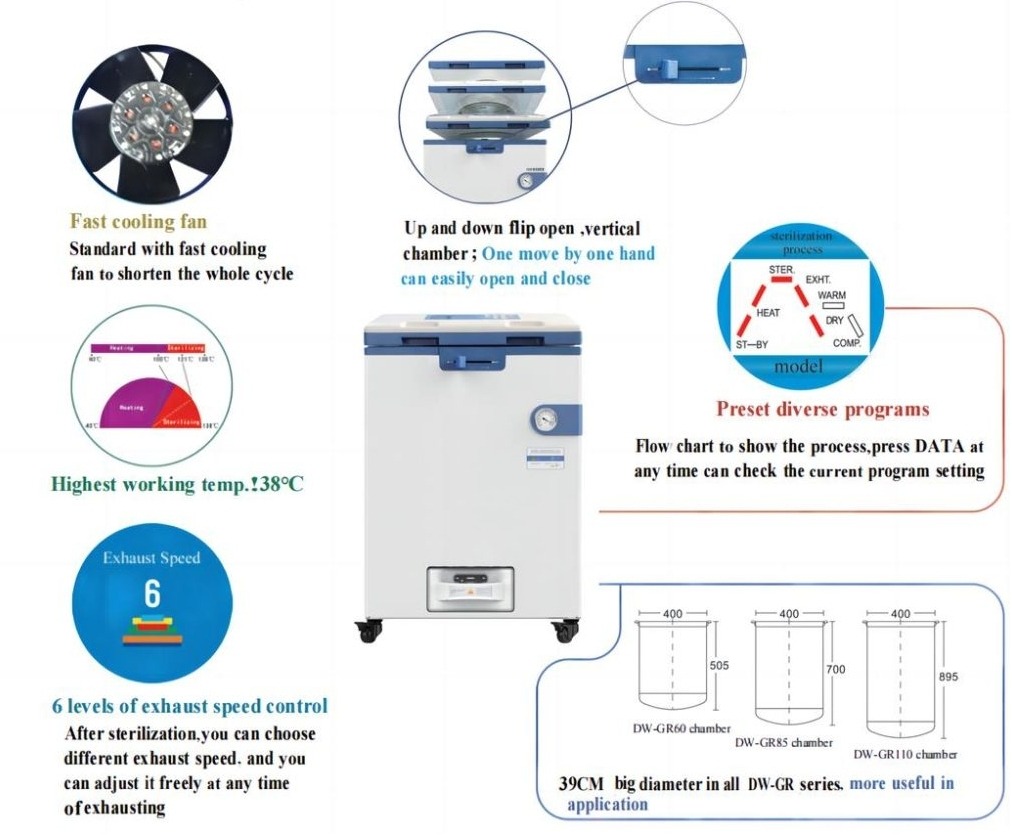

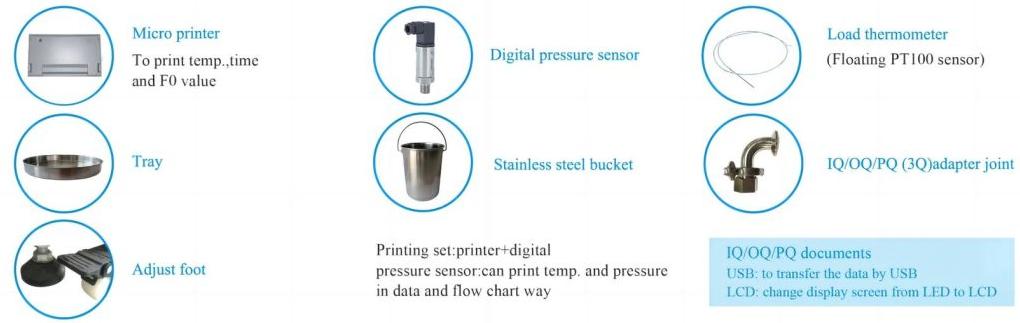

To understand what makes fully automatic vertical autoclaves so reliable, it’s essential to examine their core components. Each part is meticulously designed to ensure seamless operation, contributing to the overall efficiency and durability of the machine. Fully automatic vertical autoclave parts including:

- Pressure Chamber: The heart of the autoclave, typically made of high-grade stainless steel, capable of withstanding high temperatures and pressures without corrosion or wear.

- Control Panel: Equipped with digital or touch interfaces, this panel provides precise control over sterilization parameters like temperature, pressure, and time.

- Heating Element: A robust mechanism responsible for generating the heat required to create steam within the chamber.

- Steam Generator: Produces and regulates steam flow to ensure even heat distribution.

- Safety Valves and Indicators: Prevents overpressure and overheating, maintaining operational safety and reliability.

- Automatic Lid Locking System: Ensures the chamber remains sealed during operation, enhancing user safety and maintaining internal conditions.

- Drain Valve and Exhaust System: Efficiently removes used water and air to prepare the chamber for subsequent cycles.

Each of these components plays a vital role in the autoclave’s performance. Their seamless integration ensures that fully automatic vertical autoclaves operate with minimal human intervention, reducing the risk of errors and malfunctions.

Core Features Contributing to the Reliability

The reliability of fully automatic vertical autoclaves stems from a combination of advanced technologies and robust design principles. Let’s examine the core features that contribute to their dependable performance.

Precise Control System

Modern fully automatic vertical autoclaves are equipped with microprocessor-based control systems. These systems:

- Maintain exact temperatures and pressures required for effective sterilization.

- Provide real-time monitoring and alerts for deviations, ensuring immediate corrective action.

- Allow users to pre-set cycles, making operations consistent and predictable.

This level of precision ensures that every sterilization cycle meets stringent standards, making the process highly reliable.

Automated Processes

Automation is a cornerstone of reliability in vertical autoclaves. Fully automatic systems eliminate the need for manual adjustments by:

- Automatically filling the chamber with the correct amount of water.

- Regulating steam generation and venting processes.

- Completing sterilization cycles without constant monitoring.

By minimizing human intervention, automation reduces the likelihood of errors, ensuring consistent performance over time.

Durable Materials

The materials used in constructing these autoclaves are chosen for their strength and longevity. For example:

- Stainless steel chambers resist corrosion and wear, even under high-pressure and high-temperature conditions.

- High-quality seals and gaskets maintain the chamber’s integrity over repeated cycles.

- This durability ensures that fully automatic vertical autoclaves can handle heavy workloads without compromising performance.

Advanced Safety Features

Safety is paramount in sterilization equipment, and fully automatic vertical autoclaves excel in this area. Key safety features include:

- Overpressure Protection: Safety valves release excess pressure to prevent accidents.

- Automatic Shutdown: Systems halt operations if unsafe conditions are detected.

- Lid Interlocks: Prevent the lid from opening while the chamber is pressurized.

- Real-Time Alarms: Notify operators of potential issues, allowing prompt intervention.

These features not only protect users but also safeguard the equipment, ensuring longevity and consistent performance.

Fully automatic vertical autoclaves stand as a testament to the advancements in sterilization technology. Their reliability is rooted in their high-quality construction, precise control systems, automation, and robust safety features. By seamlessly integrating these elements, these autoclaves deliver consistent and dependable performance across a range of applications, from healthcare to research and beyond.

For professionals seeking sterilization solutions, fully automatic vertical autoclaves offer unparalleled reliability and peace of mind. Feel free to contact Drawell – Vertical Autoclave Manufacturer, to get these advanced equipment.