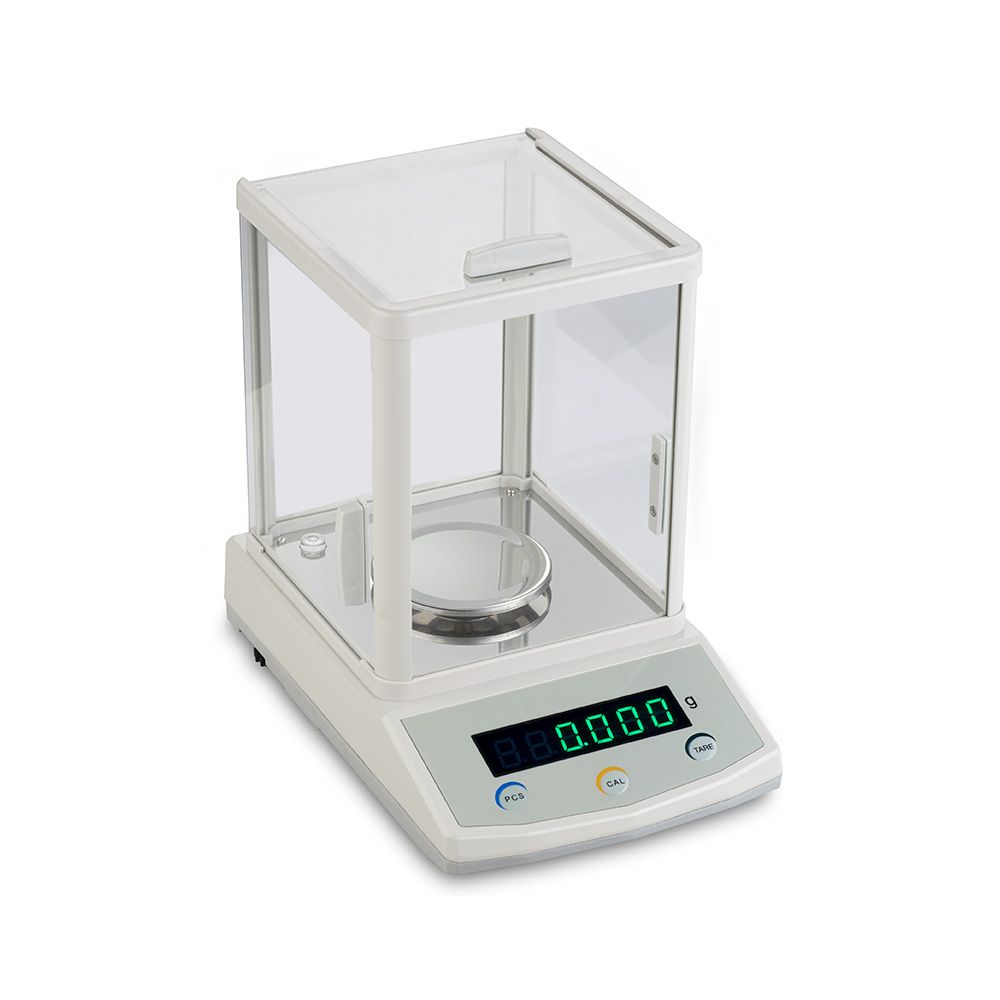

Analytical balances are indispensable equipment in laboratories, research institutions, and other businesses where precision and accuracy are critical. These extremely sensitive tools are intended to measure mass with extreme precision. In the context of analytical balancing, precision refers to the instrument’s capacity to reliably reproduce the same measurement result under identical conditions. It quantifies the level of agreement between repeated measurements, indicating the instrument’s dependability and repeatability. In this article, we will focus on the concept of what is the precision of an analytical balance, exploring the aspects of why the precision balance is important for reliable measurement, factors affecting precision, and methods of evaluating precision.

Why the Precision of an Analytical Balance Is Important?

Accurate Measurements

Precise measurements help to produce precise findings. In analytical applications, even minor changes in mass can have a major impact on the results of experiments or studies. Precise measurements reduce uncertainties and errors, resulting in data that researchers and scientists can rely on. This accuracy is crucial for making informed decisions, drawing valid conclusions, and ensuring the integrity of scientific research.

Quality Control

Pharmaceuticals, food processing, and chemical manufacture all rely significantly on analytical balances for quality control. Precise measurements are required to assure consistency, uniformity, and specification adherence. High precision analytical balances enable businesses to monitor product quality, identify variations or irregularities, and take appropriate corrective steps. This ensures that products meet regulatory criteria, are safe, and meet customer expectations.

Regulatory Compliance

Various industries are governed by tight regulatory frameworks that specify specific measuring standards. Regulatory bodies develop rules to assure consumer safety, product traceability, and quality standards compliance. High precision analytical balances are required for compliance with these rules. Accurate and precise measurements offer the paperwork and evidence needed to verify compliance, avoiding legal and financial ramifications.

Process Optimization

Precise measurements aid in process optimization in manufacturing and research. Companies may optimize manufacturing processes, reduce waste, and increase efficiency by correctly estimating and managing the mass of raw materials, intermediates, and finished goods. Precise measurements also allow for the development of new materials, equipment calibration, and the evaluation of process parameters. This optimization results in cost savings, higher product quality, and higher productivity.

Research and Development

Precision in analytical measures is critical in scientific research and development activities. It enables scientists to examine difficult scientific phenomena, test ideas, and create new materials or technologies. Precise measurements lay the groundwork for experimental data, allowing researchers to reproduce and validate conclusions. This precision is particularly important in fields such as pharmaceuticals, materials science, environmental analysis, and forensic science, where small differences in mass can have significant implications.

Data Integrity and Reproducibility

Precise measurements are critical for data integrity and reproducibility. When tests or analyses are carried out with high precision using analytical balances, the resulting data can be replicated consistently by other researchers or in multiple laboratories. This reproducibility enhances scientific discoveries, promotes peer review, and increases trust in the trustworthiness of research results.

What Are the Factors Affecting the Precision of an Analytical Balance?

Several factors can affect the precision of an analytical balance. Understanding these variables is critical for achieving accurate and consistent measurements.

Instrument Quality

The analytical balance’s quality and design are important factors in determining its precision. Precision components, innovative technology, and strong construction are used to minimize measurement variability in high-quality balances. Investing in a reputed brand and dependable model helps offer greater measurement precision.

Environmental Conditions

Environmental conditions can cause fluctuations in an analytical balance’s stability. Variations in temperature, humidity, air currents, and vibrations can all have an affect on the balance’s performance and measurement precision. To reduce the influence of these elements, it is critical to establish a stable and controlled atmosphere in the weighing area.

Calibration

Calibration is essential for assuring an analytical balance’s accuracy and precision. Calibration is the process of adjusting the balance to a recognized standard and correcting any discrepancies. Failure to calibrate the balance at regular intervals might lead to decreased precision and erroneous results.

Sample Handling

Precision measurements require proper sample management techniques. Static electricity, moisture content, and sample positioning on the weighing pan can all have an impact on measurement precision. To avoid errors and ensure consistent results, it is critical to follow prescribed methods for sample preparation, handling, and placement.

Operator Technique

The operator’s expertise and technique can have a considerable impact on measurement precision. Inconsistent balance handling, wrong weighing accessory use, and poor calibration techniques can all introduce mistakes and diminish precision. Adequate training and adherence to suitable weighing practices can help reduce the effects of operator error on measurement precision.

Weighing Conditions

Precision of the analytical balance might be affected by the amount of sample weighed. Overloading the balance by weighing significantly below its lower limit or surpassing its capacity might have an impact on measurement accuracy and precision. It is critical to use an appropriate sample size that falls within the measuring range of the balance.

Sample Quantity

The smallest increment of mass that an analytical balance can display is referred to as its readability. Higher readability balances have finer measurement increments, allowing for greater precision. It is critical to strike the right balance between readability and precision.

Readability

The readability of an analytical balance refers to the smallest increment of mass that the balance can display. Balances with improved readability have finer measurement increments, allowing for more precision. It is critical to strike a balance between readability and precision.

Time and Temperature Stability

The stability of the balance’s reading over time and with temperature changes is crucial for precision. Over long periods of time, some balances may display drift or fluctuations in measurement values or when subjected to temperature fluctuations. Ensuring good time and temperature stability of the balance is important for maintaining precision.

What Are the Methods of Evaluating the Precision of an Analytical Balance?

Several methods can be used to assess the precision of an analytical balance. These methods evaluate the agreement and consistency of balancing measurements.

Repeatability

The agreement between repeated measurements of the same sample under identical conditions is measured by repeatability.

- To assess repeatability, choose a stable and homogeneous sample.

- Weigh the sample several times using the same balance and under the same conditions.

- Calculate the measurement results’ standard deviation (SD) or relative standard deviation (RSD).

- Lower SD or RSD values indicate more repeatability and precision.

Reproducibility

The agreement between measurements conducted by various operators or using different balances in different places is measured by reproducibility. It evaluates the consistency of findings across different configurations and users. To determine reproducibility:

- Choose a stable sample.

- Measurements should be taken with numerous balances, ideally in separate places or by different operators.

- Calculate the measurement results’ standard deviation or relative standard deviation.

- Lower SD or RSD values indicate better reproducibility and precision.

Control Charts

Control charts are graphical tools that help discover variances and patterns in measurement data across time. They can be used to check the precision and stability of an analytical balance. To make a control chart, follow these steps:

- Weigh a consistent and homogeneous sample on a regular basis (e.g., hourly or daily).

- Create a control chart with the x-axis representing time and the y-axis displaying the measurement values.

- Control charts display the balance’s performance and aid in identifying variations from intended precision.

Interlaboratory Comparisons

Interlaboratory comparisons entail measuring the same sample with various balances in separate laboratories. This method assesses the agreement of measurements taken by various operators and instruments. To do an interlaboratory comparison, follow these steps:

- Choose a reliable reference sample.

- Distribute the sample to various laboratories with varying balances.

- Each laboratory uses its own balance to do measurements.

- Collect and analyze each laboratory’s measurement findings.

- Using statistical analysis, assess the consistency of the measurements.

- The consistency of results across laboratories demonstrates the precision and dependability of the balances.

Proficiency Testing Programs

External agencies establish proficiency testing programs to evaluate the measuring capabilities and precision of analytical balances. Participating in such programs enables users to evaluate the performance of their balance against set standards and compare their results to those of other laboratories. These programs assess precision independently and can help discover areas for improvement.

To get accurate and exact results, it is critical to use correct measuring techniques, follow specified protocols, and maintain frequent calibration and maintenance of the analytical balance.

Summary

The precision of an analytical balance is a critical feature that directly influences the dependability and accuracy of measurement findings. Maintaining a precision focus is critical for producing high-quality data, meeting regulatory criteria, and propelling breakthroughs in a variety of scientific and industrial disciplines.