Sulfur analysis is a crucial aspect of various industries, ranging from petroleum and environmental monitoring to pharmaceuticals and agriculture. Accurate measurement of sulfur content in samples is essential for quality control, compliance with regulations, and process optimization. Sulfur analyzers, equipped with advanced technologies and precise detection systems, play a pivotal role in achieving reliable sulfur analysis.

In this article, we will explore the components and working principles of a sulfur analyzer. By understanding the key components and the underlying principles behind its operation, we can gain insight into how does a sulfur analyzer work, which can deliver accurate and rapid sulfur analysis results.

What Are the Components of Sulfur Analyzer?

The components of a sulfur analyzer may vary depending on the specific model and manufacturer. However, here are some common components found in sulfur analyzers:

- Sample Introduction System: This component is responsible for preparing and introducing the sample into the analyzer. It may include features such as sample holders, sample injection systems, and sample pretreatment options (e.g., grinding, dissolution).

- Combustion System: The combustion system is designed to convert sulfur compounds in the sample into detectable forms. It typically includes a combustion chamber or furnace, where the sample is heated to high temperatures to facilitate the combustion process. Different combustion techniques can be employed, such as high-temperature combustion or wet oxidation.

- Detection System: The detection system is responsible for measuring the sulfur concentration in the sample after combustion. Various detection techniques can be used, depending on the analyzer’s design. Common detection methods include flame photometric detection (FPD), ultraviolet fluorescence detection (UVD), atomic absorption spectroscopy (AAS), and mass spectrometry (MS).

- Data Analysis and Reporting: This component includes the software and algorithms necessary for data analysis and reporting of sulfur analysis results. It may provide features such as calibration curves, calculation of sulfur concentrations, and data visualization tools. The reporting functionality allows users to generate comprehensive reports or export data for further analysis.

- Calibration and Quality Control: Sulfur analyzers often include calibration features to ensure accurate and reliable results. This may involve the use of calibration standards or certified reference materials (CRMs) with known sulfur concentrations. Quality control measures, such as instrument performance checks and validation using CRMs, are also incorporated to maintain the analyzer’s accuracy and precision.

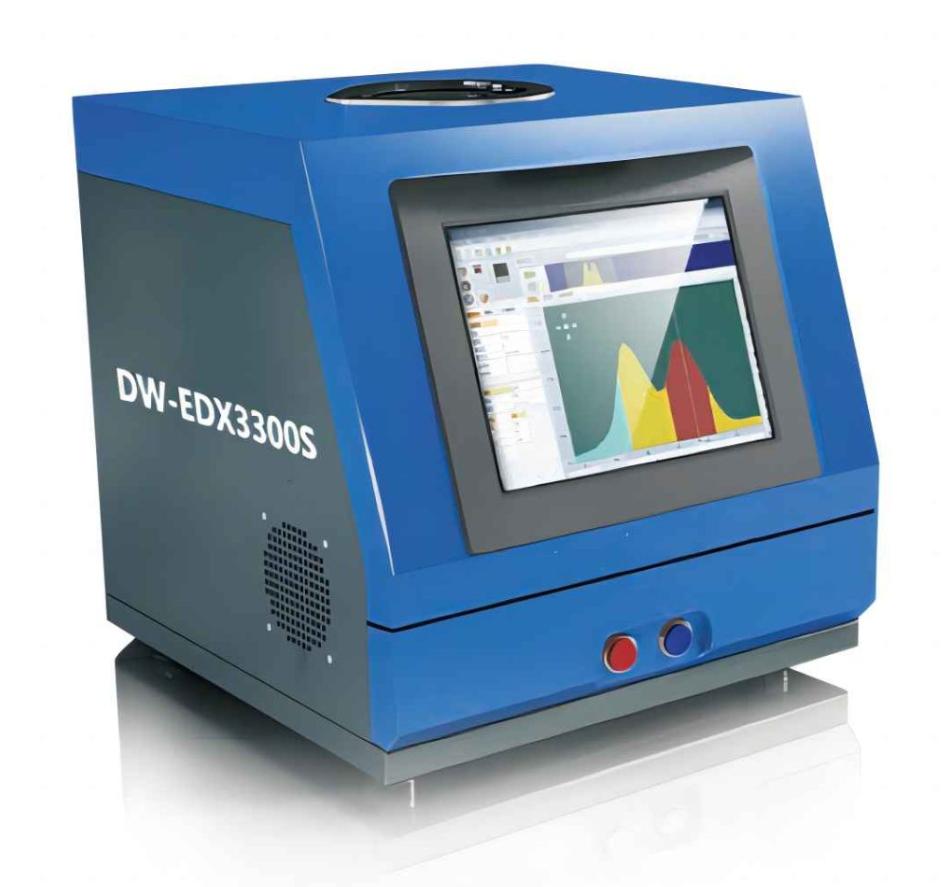

- User Interface: The user interface provides the means for interacting with the sulfur analyzer. It typically includes a graphical interface displayed on a screen, allowing users to input parameters, monitor the analysis process, and access data and reports. The user interface may also include controls for instrument settings, diagnostic tools, and troubleshooting assistance.

- Safety Features: Sulfur analyzers often incorporate safety features to protect operators and ensure safe handling of samples and chemicals. These features may include safety interlocks, alarms for abnormal conditions (e.g., high temperatures), and proper ventilation systems to handle potential hazards.

It’s important to note that the specific components and their design can vary across different sulfur analyzer models. It is advisable to refer to the documentation or specifications provided by the manufacturer for detailed information on the components of a specific sulfur analyzer.

What Are the Working Principles of Sulfur Analyzer?

The working principles of a sulfur analyzer generally involve the following steps:

- Sample Preparation and Introduction: The first step is to prepare the sample for analysis. This may involve grinding solid samples, dissolving or diluting liquid samples, or preparing gas samples. The prepared sample is then introduced into the analyzer, typically through a sample introduction system.

- Combustion Process: Once the sample is introduced into the analyzer, the sulfur compounds present in the sample need to be converted into detectable forms. This is achieved through the combustion process. The combustion system, which includes a combustion chamber or furnace, heats the sample to high temperatures. Different combustion techniques can be employed, such as high-temperature combustion or wet oxidation.

- Detection and Measurement: After the combustion process, the sulfur compounds are converted into detectable species. The detection system in the analyzer measures the concentration of sulfur present in the sample. Various detection techniques can be used depending on the analyzer’s design. Common techniques include flame photometric detection (FPD), ultraviolet fluorescence detection (UVD), atomic absorption spectroscopy (AAS), and mass spectrometry (MS).

- Flame Photometric Detection (FPD): FPD relies on the principle that when sulfur-containing compounds are combusted, they produce sulfur dioxide (SO2) and other sulfur compounds. The emitted sulfur compounds are then excited by a flame and the resulting photons emitted during de-excitation are detected, allowing the measurement of sulfur concentration.

- Ultraviolet Fluorescence Detection (UVD): UVD involves the excitation of sulfur compounds by ultraviolet light. When sulfur-containing compounds are combusted, they produce sulfur dioxide (SO2), which emits characteristic fluorescence when excited by UV light. The emitted fluorescence is measured to determine the sulfur concentration.

- Atomic Absorption Spectroscopy (AAS): AAS uses the absorption of light by sulfur atoms in the vapor state. Sulfur-containing compounds are combusted, and the resulting sulfur atoms are vaporized. The absorption of light at specific wavelengths by the sulfur atoms is measured to determine the sulfur concentration.

- Mass Spectrometry (MS): MS involves the ionization of sulfur-containing compounds and the separation of ions based on their mass-to-charge ratio. The sulfur compounds in the sample are ionized, and the resulting ions are separated and detected based on their mass-to-charge ratio, allowing for accurate sulfur quantification.

- Data Analysis and Reporting: The sulfur analyzer includes software and algorithms for data analysis and reporting. The raw measurement data obtained from the detection system is processed, calibrated, and converted into sulfur concentrations. The analyzer may generate calibration curves, perform calculations, and apply calibration factors to determine accurate sulfur concentrations. The results can be presented in various formats, including numerical values, graphs, or comprehensive reports.

It’s important to note that the specific working principles may vary depending on the type and model of the sulfur analyzer. Different analyzers may utilize different combustion techniques, detection methods, and data analysis algorithms. Therefore, it is recommended to consult the manufacturer’s documentation or user manual for detailed information on the working principles of a particular sulfur analyzer.

As a professtional analytical instrument manufacturer, Drawell can provide you documentation or user manual of all of our products, please feel free to contact us when you need help.