In the world of laboratory centrifuges, understanding the concepts of RPM (Revolutions Per Minute) and RCF (Relative Centrifugal Force) is crucial for making informed purchasing decisions. These parameters are fundamental to the operation and effectiveness of a centrifuge, influencing the separation of samples and the overall performance of the device. This guide aims to elucidate the differences between RPM and RCF, their respective roles, and how to choose the right settings for your specific applications.

Understanding RPM and RCF

Centrifuges operate by spinning samples at high speeds to generate centrifugal force, which separates components based on their densities. The effectiveness of this separation depends on the RPM and RCF.

What is RPM?

RPM stands for Revolutions Per Minute, a measure of how many times the centrifuge rotor completes a full rotation in one minute. It is a direct indicator of the speed at which the centrifuge is operating. For instance, a centrifuge operating at 10,000 RPM completes 10,000 full turns in a minute. RPM is a straightforward value often displayed on centrifuge control panels.

Higher RPM values indicate faster spinning, which generally translates to greater centrifugal force applied to the samples. However, RPM alone does not account for the rotor size, which also impacts the actual force exerted on the samples.

What is RCF?

RCF, or Relative Centrifugal Force, is a more accurate representation of the centrifugal force acting on samples during centrifugation. It is expressed as a multiple of the Earth’s gravitational force (g). RCF considers both the rotational speed (RPM) and the radius of the rotor. A higher RCF indicates a stronger centrifugal force, which is essential for separating components with similar densities.

RCF is the preferred unit for specifying centrifugation conditions as it allows for direct comparison between different centrifuges and rotors.

RPM vs. RCF: Which is More Important?

While RPM is a commonly used term, RCF is the more critical parameter for centrifuge performance and experimental reproducibility. RCF directly correlates with the separation efficiency and is essential for achieving desired results.

Consider the following:

- Different rotors have different radii. Even if two centrifuges operate at the same RPM, they may generate different RCF values due to varying rotor sizes.

- RCF is consistent across different centrifuges. If you know the required RCF for your experiment, you can achieve the same results using different centrifuges by adjusting the RPM accordingly.

- Many centrifuge protocols specify RCF. This ensures standardized conditions and comparability between experiments.

In conclusion, while RPM provides a basic understanding of centrifuge speed, RCF is the key factor to consider for accurate and reproducible centrifugation results.

Choosing the Right Centrifuge RPM and RCF for Your Application

Selecting the appropriate RPM (Revolutions Per Minute) and RCF (Relative Centrifugal Force) settings for your centrifuge is essential for achieving accurate and effective sample separation. The right settings depend on the nature of your samples, the specific application, and the type of centrifuge and rotor you are using. This guide will help you determine the best RPM and RCF settings for your laboratory needs.

1. Understand Your Application Needs

Different laboratory applications require specific centrifugal forces to achieve optimal separation. Understanding the nature of your samples and the desired outcome is the first step in choosing the right RPM and RCF.

Cell Separation: For gentle separation of cells, lower RCF values (around 200-500 g) are typically sufficient.

Protein Purification: Moderate RCF values (up to 20,000 g) may be required for isolating proteins.

DNA/RNA Extraction: Higher RCF values (20,000 g and above) are often needed for efficient nucleic acid separation.

Density Gradient Centrifugation: Specific applications may require precise RCF settings to create and maintain density gradients.

2. Consider Sample Volume and Rotor Type

The volume of the sample and the type of rotor being used significantly influence the choice of RPM and RCF.

Sample Volume: Larger volumes generally require lower RPM to avoid sample spillage and ensure balanced centrifugation. Smaller volumes can be spun at higher RPMs for quicker separation.

Fixed-Angle Rotors: Suitable for pelleting applications and can handle higher RPMs.

Swing-Bucket Rotors: Ideal for density gradient separations but may require lower RPMs to maintain gradient integrity.

3. Pilot Runs and Adjustments

Conducting pilot runs allows you to fine-tune your centrifuge settings for optimal performance.

- Initial Runs: Start with the recommended RPM and RCF settings from protocols or manufacturer guidelines.

- Observations: Monitor the separation results and make note of any inconsistencies or issues.

- Adjustments: Based on your observations, make incremental adjustments to RPM and RCF to achieve the desired separation. Ensure that changes are within the safety limits specified by the manufacturer.

Then, who is a reliable centrifuge manufacturer and supplier? We recommend Drawell.

Drawell – A Reliable Centrifuge Manufacturer and Supplier

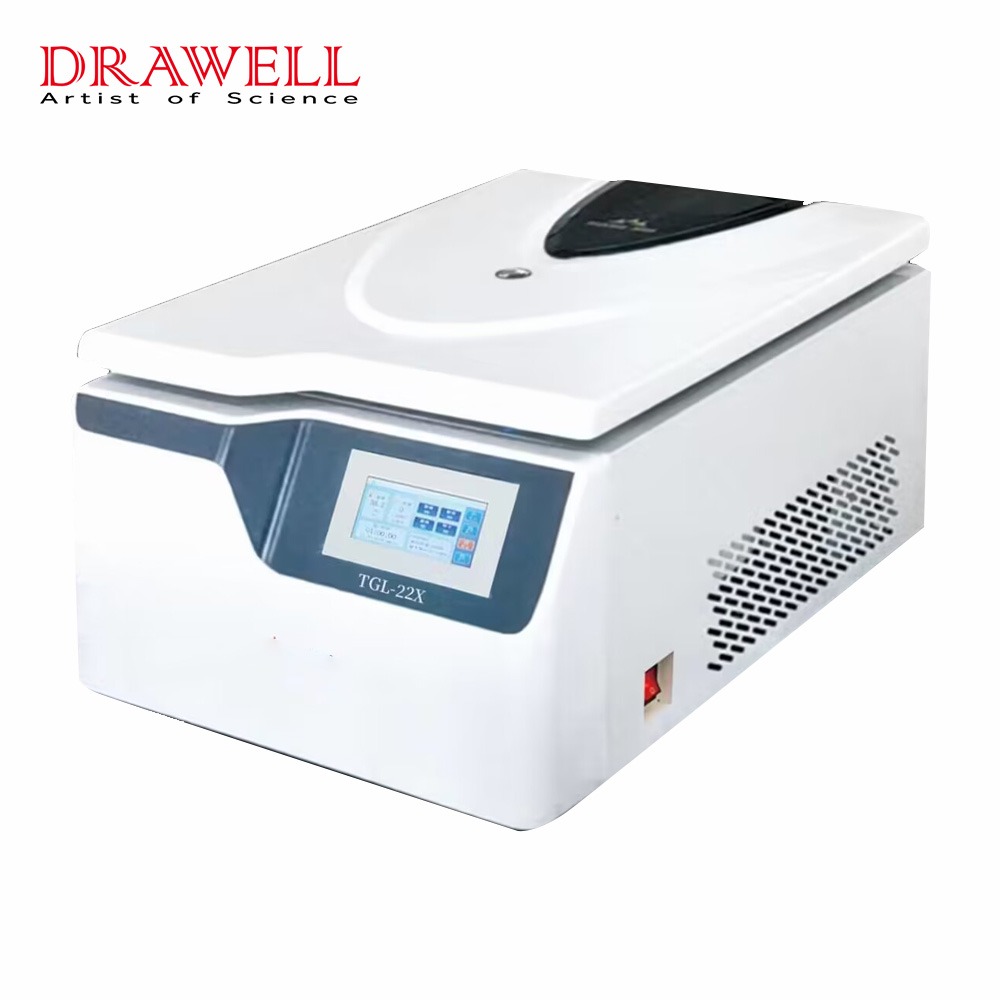

Drawell, a leading manufacturer of laboratory equipment, offers a range of centrifuges that stand out for their quality, reliability, and advanced features.

Advanced Technology and Innovation

Drawell is committed to incorporating the latest technological advancements in their centrifuges, ensuring top-notch performance and reliability.

- High-Performance Motors: Drawell centrifuges are equipped with powerful motors that provide consistent and reliable performance, even under heavy use.

- Digital Controls: Advanced digital interfaces allow for precise control over RPM and RCF settings, ensuring reproducible results.

- Safety Features: Innovations like imbalance detection, automatic shut-off, and secure lid locking mechanisms enhance user safety.

Versatile Product Range

Drawell offers a diverse range of centrifuges designed to meet various laboratory needs, from small benchtop models to high-capacity floor-standing units.

- Benchtop Centrifuges: Compact and efficient, ideal for laboratories with limited space.

- High-Speed Centrifuges: Capable of reaching high RPMs and RCFs, suitable for demanding applications like DNA/RNA extraction.

- Refrigerated Centrifuges: Maintain sample integrity by controlling temperature during centrifugation, essential for temperature-sensitive samples.

- Microcentrifuges: Designed for small-volume samples, offering precision and convenience for routine laboratory tasks.

Drawell’s emphasis on quality and reliability ensures that their centrifuges deliver consistent performance and long-term durability. The user-friendly design of Drawell centrifuges enhances laboratory efficiency and ensures a positive user experience. Their commitment to customer support and service ensures that you receive the help you need to keep your centrifuge running smoothly. These benefits make Drawell centrifuges an excellent choice for any laboratory seeking efficient, reliable, and user-friendly centrifugation solutions.

Conclusion

RPM and RCF are essential terms to grasp when working with centrifuges. While RPM indicates the rotational speed, RCF is the true measure of the centrifugal force acting on samples. Prioritizing RCF in centrifuge selection ensures accurate and reproducible results. By understanding the interplay between these parameters, you can make informed decisions to optimize your centrifugation processes.