Moisture analysis is a critical component in various industries, playing a pivotal role in ensuring the quality, reliability, and compliance of materials. One indispensable tool for this purpose is the moisture analyzer. In this article, we will delve into what a moisture analyzer is, its working principles, and provide a comprehensive guide on how to use this essential instrument.

Functions of Moisture Analyzer

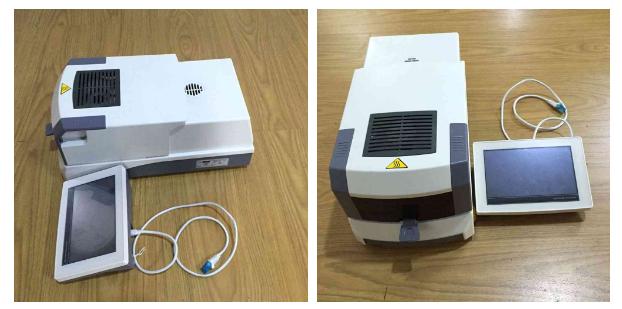

A moisture analyzer, also known as a moisture balance, is a precision instrument designed to measure the moisture content of a substance. This substance could be anything from food products and pharmaceuticals to chemicals, plastics, and more. The analyzer utilizes a combination of heat and weight measurements to determine the moisture content accurately.

Working Principles of Moisture Analyzer

The basic working principle of a moisture analyzer involves the application of heat to the sample material. Most moisture analyzers use a halogen heating lamp to dry the sample. The sample is placed in a weighing pan and the initial weight is recorded. The heating lamp is then turned on and the sample is heated until it reaches a constant weight. This indicates that all of the moisture has evaporated from the sample. The final weight of the sample is then recorded and the moisture content is calculated as the difference between the initial and final weights.

Types of Moisture Analyzer

There are two main types of moisture analyzers: standard and halogen.

- Standard moisture analyzers: These analyzers use a ceramic heating element to dry the sample. They are less expensive than halogen moisture analyzers, but they are also slower and less accurate.

- Halogen moisture analyzers: These analyzers use a halogen heating lamp to dry the sample. They are more expensive than standard moisture analyzers, but they are also faster and more accurate.

How to Use Moisture Analyzer

1. Sample Preparation

Begin by preparing a representative sample. Ensure it is homogeneous, free from contaminants, and accurately represents the material in question.

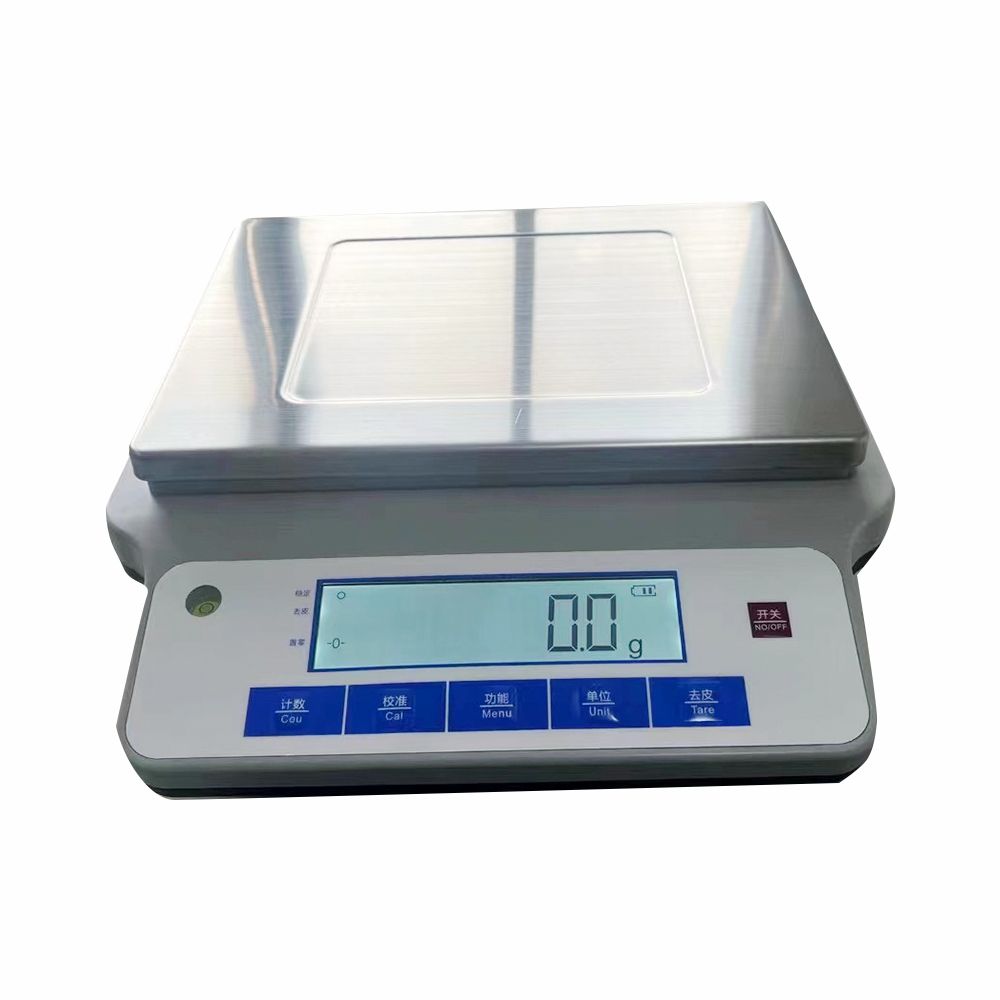

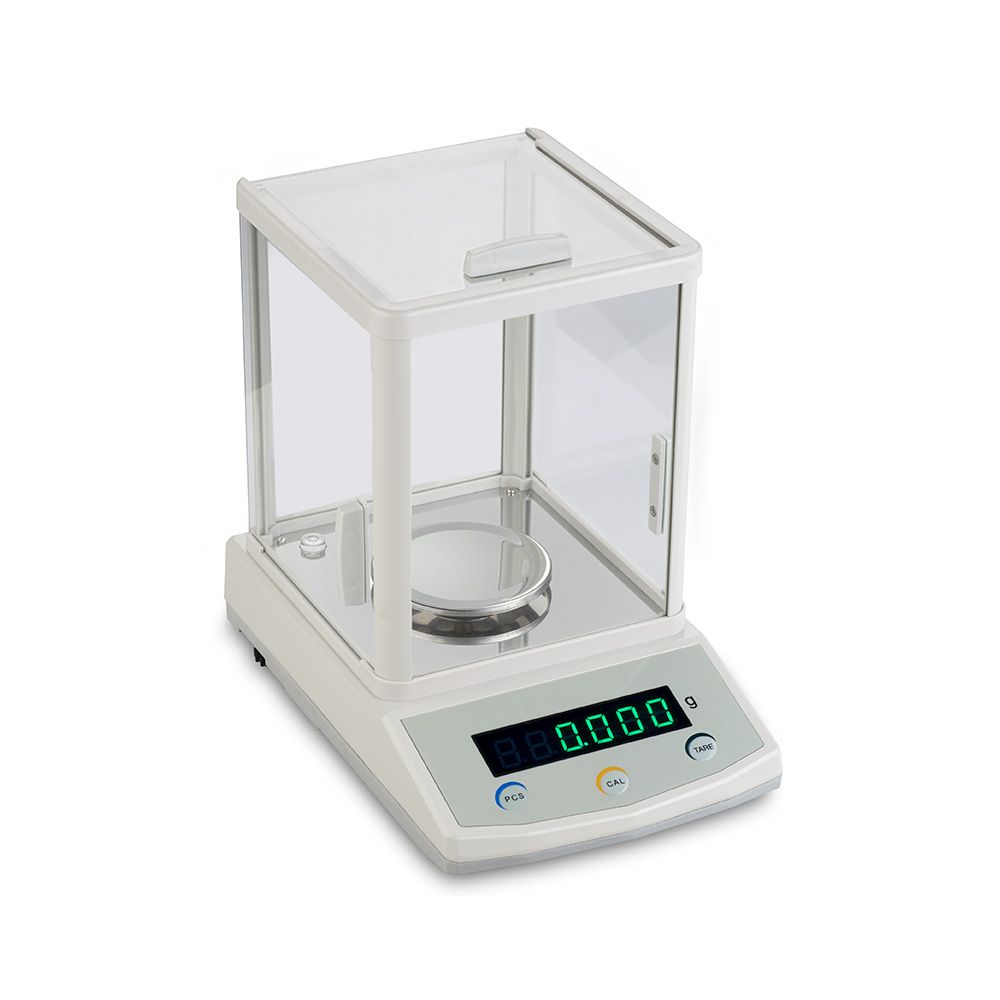

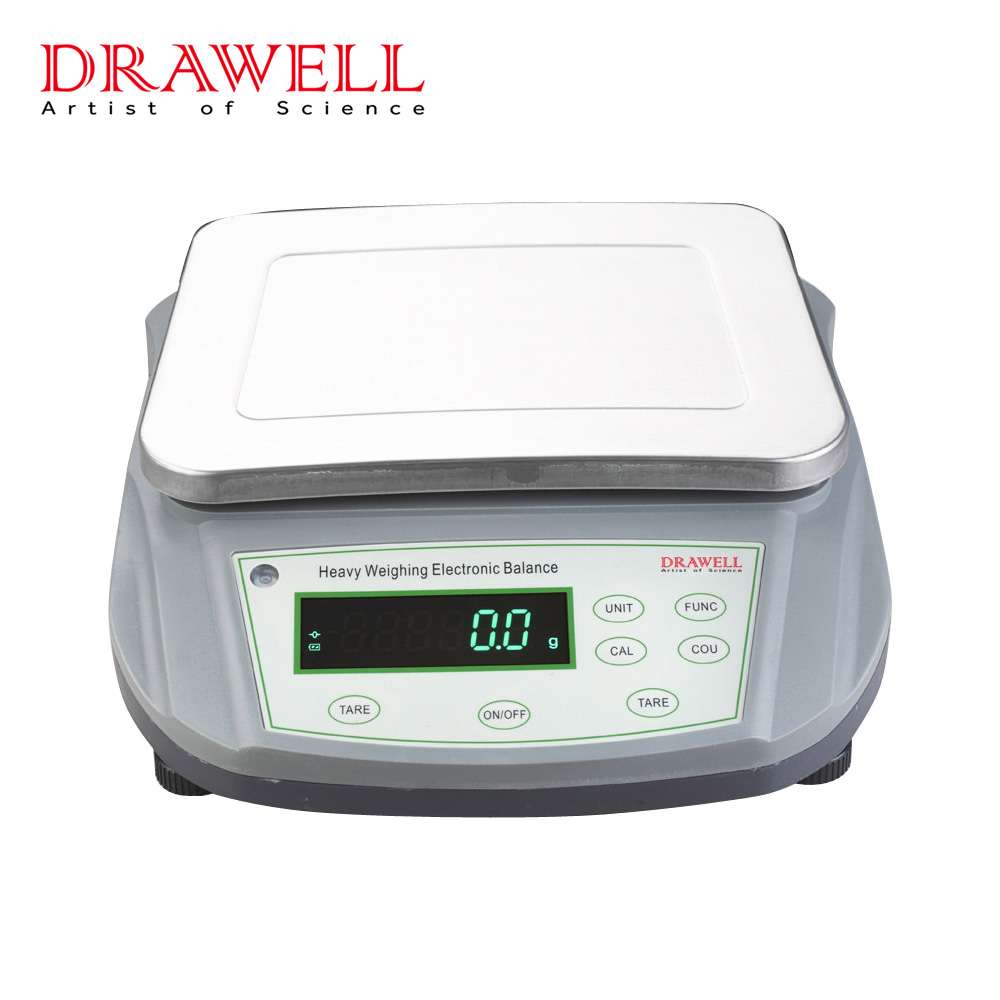

2. Weighing the Sample

Precisely weigh the sample using a balance and record the initial weight. This weight will be used as a reference throughout the analysis.

3. Loading the Sample

Place the sample in the moisture analyzer pan, ensuring an even distribution. Close the lid securely to prevent heat loss during the analysis.

4. Setting Parameters

Input the necessary parameters into the moisture analyzer, such as the desired temperature and analysis time. These parameters may vary based on the type of material being tested.

5. Initiating the Analysis

Start the moisture analysis process. The moisture analyzer will apply heat to the sample and continuously monitor the weight change until a stable endpoint is reached.

6. Results and Interpretation

Once the analysis is complete, the moisture analyzer provides a percentage of moisture content in the sample. Interpret these results in the context of your industry standards and quality requirements.

7. Calibration and Maintenance

Regularly calibrate the moisture analyzer using standard reference materials. Routine maintenance, such as cleaning and verification, is essential to ensure accurate and reliable results.

Conclusion

Incorporating a moisture analyzer into your quality control processes can significantly enhance product quality, streamline manufacturing processes, and ensure compliance with industry standards. By understanding the principles behind moisture analysis and following proper usage guidelines, you can harness the full potential of this indispensable tool for precise and efficient moisture content determination.