Fourier Transform Infrared Spectrometer is referred to as FTIR Spectrometer or Fourier Infrared Spectrometer. It differs from the principle of dispersive infrared spectroscopy and is an infrared spectrometer developed based on the code of Fourier transform of the infrared light after interference.

How does Fourier Transform Infrared Spectroscopy (FTIR) work?

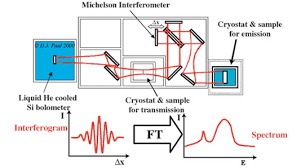

Light from an FTIR light source is split into two beams by a beam splitter (similar to a half mirror). One beam is transmitted to the moving mirror and the other beam is reflected by the fixed mirror.

The two beams of light are reflected by the “fixed mirror” and “moving mirror” respectively, and then return to the beam splitter. The “moving mirror” is a uniform linear motion. Therefore, the two beams split by the beam splitter form an optical path difference and cause interference.

After the two beams are converged by the beam splitter, the interference light passes through the placed sample cell, and after passing through the sample, the interference light containing the sample information reaches the detector, and then the signal is Fourier transformed, and finally, the transmittance is obtained. It obtains absorbance at wavenumber or wavelength.

FTIR Main Features

1. High signal-to-noise ratio: The Fourier transform infrared spectrometer uses few optical components, no grating or prism beam splitter, which reduces the loss of light, and further increases the light signal through interference. Thus, the radiation intensity reaching the detector is large, the signal-to-noise ratio is high.

2. Good reproducibility: The Fourier transform of Fourier transform infrared spectrometer is used to process the light signal, which avoids the error caused by the motor-driven grating light splitting. Thus, the reproducibility is better.

3. Fast scanning speed: The Fourier transform infrared spectrometer collects data according to the whole waveband, and the obtained spectrum is the result of averaging multiple data collections. It only takes one to several seconds to complete a complete data collection, while the dispersion Type instruments need to test only a very narrow frequency range at any instant. Besides, a complete data acquisition takes ten to twenty minutes.

In short, infrared spectroscopy has the characteristics of strong characteristics, rapid analysis, no damage to the sample, less sample consumption, easy operation, analyzing samples in various states, high analytical sensitivity, and a wide range of applications (solid, liquid or It can be applied to gaseous samples; inorganic, organic, and polymer compounds can be detected) and other characteristics. It is combined with chromatography (GC-IR) or TGA (TGA-IR) and has powerful qualitative functions.

What problems can Fourier transform infrared spectrometers solve?

- Identification of known objects.

- Structure identification of unknowns.

- Quantitative analysis of special materials.

- Micro-infrared can analyze trace substances such as residues on the surface of the product, powder/liquid precipitated on the surface, suspected oxidation, corrosion, foreign matter, and introduction of foreign components on the surface of the product.

Among them, FTIR has an excellent performance in determining the consistency of polymer materials.

Due to the different types of groups in different substances, the groups are arranged in different ways, and this difference will reflect different spectral peaks on the infrared spectrum. Therefore, there will be some differences in the fingerprints of the infrared spectra. By comparing the infrared spectra, the differences in the compounds contained in the samples or the differences in the structure of the compounds can be obtained, determining the material consistency of different samples. Usually, the consistency of materials needs to be combined with a multi-dimensional comprehensive analysis of product component content, product physical and chemical properties, etc. to obtain better consistency analysis results.

Application areas: unprocessed plastic raw materials (granules) or processed homogeneous plastic parts (such as housings, supporting live parts, etc.); printed circuit boards (PCB boards).

The purpose of material consistency determination:

- Solve the abnormal problem of the product from the aspect of the material.

- Monitor the product to determine whether the material has the same ingredients, the same batch, and the same manufacturer.

- It can effectively control the excessive use of recycled materials or scraps by plastic material suppliers.

- Reverse analysis of products, accurate qualitative unknown materials, and cost savings.