In the realm of analytical chemistry, precision and accuracy are paramount. Understanding the composition of materials is fundamental to numerous industries, from metallurgy to environmental science. One indispensable tool that enables us to explore the chemical makeup of substances is the Carbon and Sulfur Analyzer. This instrument, often overlooked but critical in various fields, plays a significant role in ensuring the quality of products, the efficiency of processes, and the preservation of our environment. In this comprehensive article, we will delve into the inner workings of the Carbon and Sulfur Analyzer, its applications, and how to choose the right one for your specific needs.

What are the Functions and Types of Carbon and Sulfur Analyzer

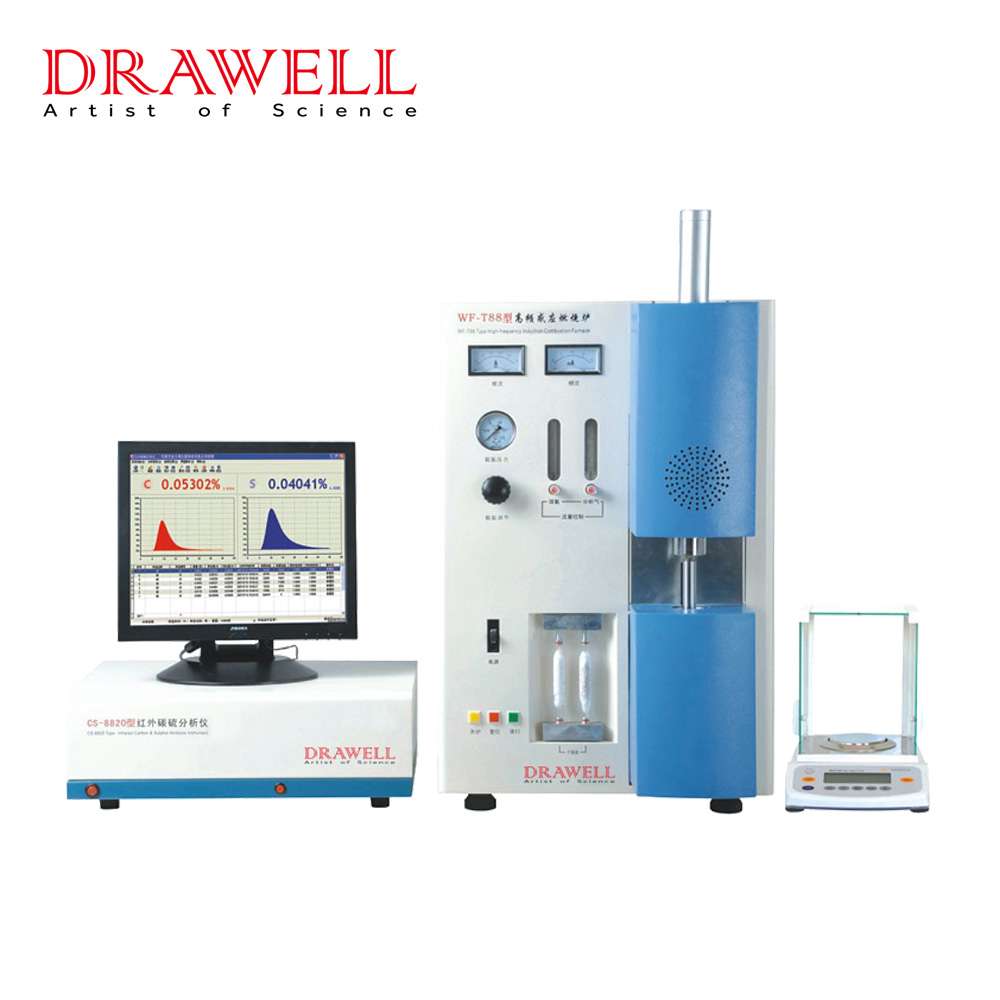

A carbon and sulfur analyzer is a device used to measure the content of carbon and sulfur in materials. These instruments typically work by combusting the sample and then measuring the amount of carbon dioxide (CO2) and sulfur dioxide (SO2) produced in the combustion process.

There are two main types of carbon and sulfur analyzers:

- Elemental analyzers: These instruments are used to measure the total carbon and sulfur content in a sample. Elemental analyzers are typically used for research and development purposes, or for quality control in industries where high precision is required.

- Process analyzers: These instruments are used to measure the carbon and sulfur content in a continuous stream of material. Process analyzers are typically used in industrial settings to monitor and control the composition of products.

How Does Carbon and Sulfur Analyzer Work?

Carbon and Sulfur Analyzers operate on the principle of high-temperature combustion, which involves several essential steps:

- Sample Preparation: The first crucial step is preparing the sample for analysis. It is essential to ensure that the sample is representative and adequately homogenized to obtain accurate results.

- Combustion: Once the sample is prepared, it is placed into a combustion tube or crucible within the analyzer’s combustion chamber. The instrument then raises the temperature to a level where the carbon and sulfur within the sample oxidize to form CO2 and SO2.

- Gas Separation: After combustion, the gases produced are separated using various methods, such as gas chromatography or thermal conductivity. This separation is necessary to distinguish between the carbon dioxide and sulfur dioxide gases.

- Detection: The separated gases are then quantified using appropriate detectors, such as infrared detectors for CO2 and UV fluorescence detectors for SO2. The measurements are based on the specific absorption characteristics of these gases.

- Calculation: Finally, the analyzer performs calculations based on the detected gas concentrations to determine the carbon and sulfur content of the sample. The results are usually displayed in percentage or parts per million (ppm).

What are the Applications of Carbon and Sulfur Analyzer

Carbon and sulfur analyzers are used in a wide variety of industries to measure the carbon and sulfur content in materials. This information can be used to ensure the quality of products, optimize industrial processes, and comply with environmental regulations.

Here are some specific examples of how carbon and sulfur analyzers are used in different industries:

- Energy: Carbon and sulfur analyzers are used to measure the carbon and sulfur content in coal, petroleum, and natural gas. This information is used to assess the quality of these fuels and to optimize their combustion.

- Metals: Carbon and sulfur analyzers are used to measure the carbon and sulfur content in steel, aluminum, and copper. This information is used to ensure the quality of these metals and to optimize their production processes.

- Cement: Carbon and sulfur analyzers are used to measure the carbon and sulfur content in cement and other construction materials. This information is used to ensure the quality of these materials and to optimize their production processes.

- Food and agriculture: Carbon and sulfur analyzers are used to measure the carbon and sulfur content in food and agricultural products. This information is used to ensure the quality of these products and to comply with food safety regulations.

- Environmental: Carbon and sulfur analyzers are used to measure the carbon and sulfur content in air, water, and soil. This information is used to monitor air quality, water quality, and soil quality.

Measurement techniques

There are a variety of different measurement techniques used in carbon and sulfur analyzers. The most common measurement techniques are:

- Infrared spectroscopy: This technique measures the absorption of infrared light by the CO2 and SO2 molecules. Infrared spectroscopy is a relatively simple and inexpensive measurement technique, but it can be less accurate and precise than other measurement techniques, such as gas chromatography.

- Gas chromatography: This technique separates the CO2 and SO2 molecules from other gases in the sample. The separated gases are then passed through a detector, which measures the amount of each gas present. Gas chromatography is a more accurate and precise measurement technique than infrared spectroscopy, but it is also more expensive and complex.

- Chemiluminescence: This technique measures the light emitted by the reaction between SO2 and ozone (O3). Chemiluminescence is a very sensitive measurement technique, but it can be more expensive and complex than other measurement techniques, such as infrared spectroscopy.

How to Choose the Right Carbon and Sulfur Analyzer

Selecting the right Carbon and Sulfur Analyzer is a critical decision that depends on various factors. Consider the following aspects when choosing the analyzer that best suits your needs:

- Sample Type and Size: Different analyzers are optimized for specific sample types and sizes. Ensure that the instrument you choose can accommodate your sample requirements.

- Detection Limits: The analyzer’s detection limits for carbon and sulfur are essential, especially if you need high precision in your analysis. Some applications demand extremely low detection limits, so be sure to match your requirements with the analyzer’s capabilities.

- Analysis Speed: The analysis speed of an analyzer can vary significantly. For high-throughput applications, you’ll want an instrument that delivers quick results without sacrificing accuracy.

- Automation: Depending on your workflow, consider whether automation features such as auto-sampling and data handling are necessary for your application.

- Calibration and Maintenance: Check the ease of calibration and maintenance for the analyzer. Complicated calibration procedures and high maintenance requirements can add to operational costs and downtime.

- Compatibility: Ensure that the analyzer is compatible with the specific methods and standards relevant to your industry or application.

- Cost: Budget considerations are crucial. It’s essential to balance your budget with the features and capabilities you require. Remember that a high-quality instrument may provide better long-term value, as it is less likely to require frequent maintenance or replacement.

- Technical Support and Training: Consider the availability of technical support and training options. Having access to expert assistance and training resources can be invaluable for successful operation and troubleshooting.

- Reputation and Reviews: Look for reviews and testimonials from other users to gauge the real-world performance of the analyzer and the reputation of the manufacturer.

- Compliance: Ensure that the analyzer meets relevant industry and safety standards. This is especially important for regulated industries such as pharmaceuticals and environmental monitoring.

Summary

Carbon and Sulfur Analyzers are the unsung heroes of analytical chemistry, playing a pivotal role in ensuring product quality, process efficiency, and environmental sustainability across diverse industries. This article has illuminated the intricate workings of these instruments, highlighting their ability to convert carbon and sulfur into measurable gases through high-temperature combustion.

Choosing the right analyzer is a critical decision, demanding consideration of factors like sample type, detection limits, analysis speed, automation, compatibility, cost, and technical support. By making an informed choice, you can ensure that your analyzer aligns seamlessly with your specific requirements, enhancing the success of your applications.

In conclusion, Carbon and Sulfur Analyzers exemplify the amalgamation of science and technology, quietly advancing progress in numerous fields. Their precision and accuracy underscore their significance in today’s ever-evolving world, where understanding the elemental composition of materials remains paramount.