Alloy analyzer was born based on X-ray theory. It is mainly used for field determination of elemental composition in metal materials in military, aerospace, steel, petrochemical, electric power, pharmaceutical, and other fields.

How Does the Alloy Analyzer Work?

The alloy analyzer is a kind of XRF spectroscopy analysis technology, which can be used to confirm the specific elements in the substance and quantify them at the same time. It can determine the specific element according to the emission wavelength (λ) and energy (E) of the X-ray and determine the amount of this element by measuring the density of the corresponding ray. In this way, XRF can determine the elemental composition of substances.

Each atom has its fixed number of electrons (negatively charged particles) running in orbits around the nucleus. And the number of electrons is equal to the number of protons (positively charged particles) in the nucleus. From the number of atoms in the periodic table, we can know the number of protons. Each atomic number corresponds to a fixed element name, such as iron, the element name is Fe, and the atomic number is 26. Through the special research of energy-dispersive X fluorescence and wavelength dispersive X fluorescence spectral analysis technology, and applied to the three innermost electron orbitals, namely K, L, and M. Among them, the K orbital is closest to the nucleus, and each electron orbital corresponds to a certain element with a specific energy layer.

In XRF analysis, photons of high-energy primary rays emitted from the X-ray emission tube hit the sample element. These primary photons contain enough energy to derail the innermost electrons, namely the K layer or the L layer. At this time, the atom becomes an unstable ion. Since the electrons instinctively seek stability, the electrons in the outer L layer or M layer will enter the space that makes up the inner layer. As these electrons enter the inner layer from the outer layer, they release energy, which we call secondary X-ray photons.

The whole process is called fluorescent radiation. The secondary rays of each element will have different characteristics. The amount of energy produced by X-ray photon fluorescence radiation is determined by the energy difference between the inner layer and the outer layer during the electron conversion process. For example, the Kα energy of an iron atom Fe is approximately 6.4 kiloelectron volts. The number or density of X-rays emitted by a specific element in a certain period can be used to measure the quantity of this element. A typical XRF energy distribution spectrum shows the distribution of photon density at different energies.

What Is the Purpose of an Alloy Analyzer?

The most important function of the alloy analyzer is to measure the composition of the material. The most important function of the alloy analyzer is to identify the composition of the material. Material composition identification (PMI) plays an important role in the manufacturing, petrochemical, and consumer goods production industries.

In the manufacturing process, not only need to use the right metals and alloys in the right place but also the material composition must be free of deviations. X-ray fluorescence (XRF) analysis is highly efficient in judging the components of parts. A simple method helps to confirm whether the metals and alloys used are correct.

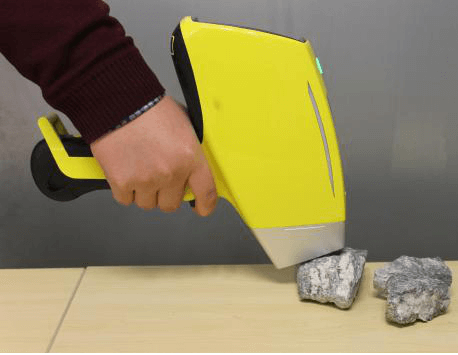

The Handheld Alloy Analyzer is a portable alloy analyzer. Only need to prepare a small number of samples, you can quickly provide test results. The identification of alloy composition is one of the common applications of XRF. If the alloy composition of a handheld spectrometer is used to identify the alloy composition, the alloy type can usually be determined in a short time of 1 to 2 seconds.

What Should I Pay Attention to When Using a Handheld Alloy Analyzer?

When using a handheld X-ray fluorescence spectrometer (handheld alloy analyzer) to determine the composition of materials, three important factors that need to be considered are mainly as follows.

Material Composition

The handheld spectrometer alloy analyzer can quantitatively analyze more than 90% of the elements in the periodic table: from magnesium to heavier elements. These measurable elements cover most of the elements used in commercial alloys. This detection ability of the XRF analyzer can obtain aluminum alloy, stainless steel, chromium-molybdenum alloy or base alloy, bronze alloy, various other copper alloys, solder, titanium alloy, tool steel, nickel, cobalt according to the obtained material composition information. Elements Many of the so-called “superalloys” can be brand-matched. However, the handheld alloy analyzer cannot directly detect elements lighter than magnesium. Undetectable elements include alloying elements such as lithium, beryllium, and carbon.

The Surface Temperature of the Alloy Analyzer Sample

The physical properties of X-rays used in XRF analysis technology hardly change with changes in sample temperature. In addition, the design goal of the analysis device is not to be affected by changes in environmental conditions and to always exert reliable measurement performance. When the analyzer is operating in the temperature range of -10 °C to 50 °C, thermal drift and performance degradation will not occur.

The alloy analyzer is not modified, and the sample can be measured normally when the sample temperature reaches about 100 °C. However, when the temperature exceeds this temperature, the polypropylene fiber film that is a part of the analyzer window may be damaged.

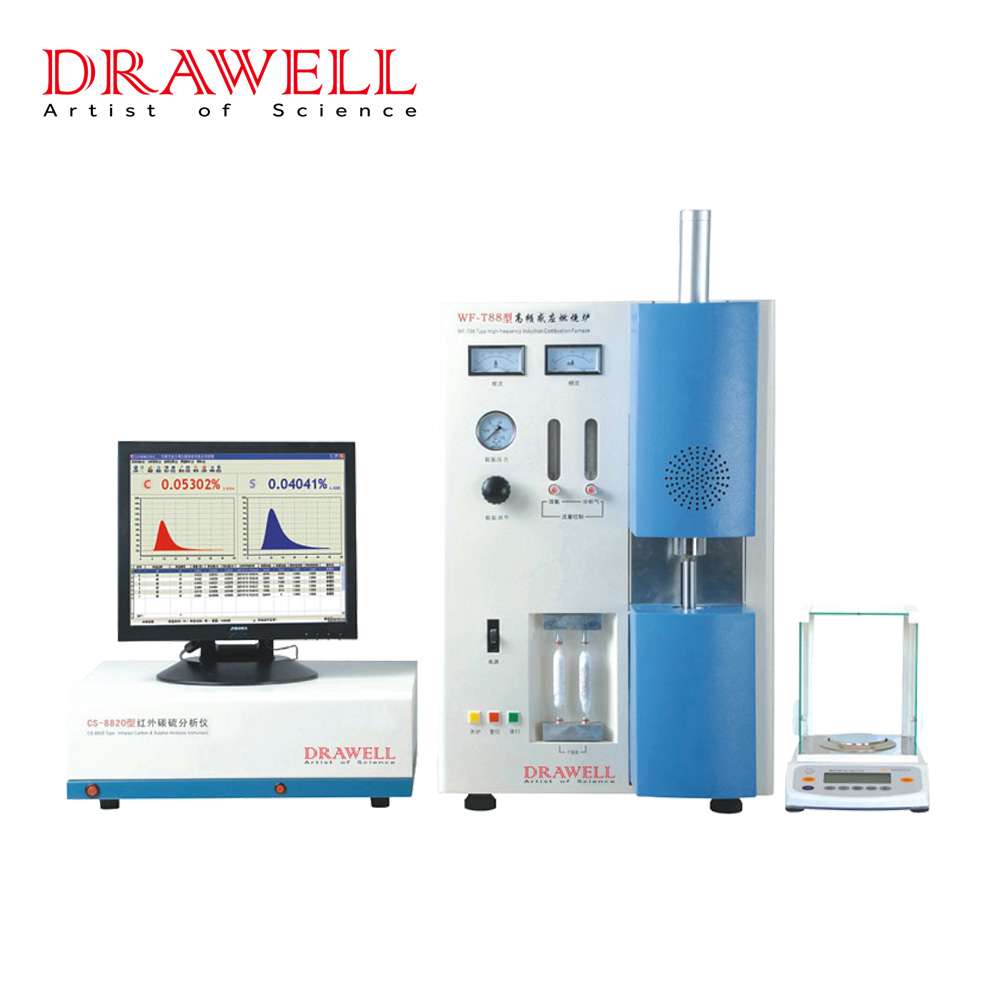

Recommended by manufacturers of high-quality handheld alloy analyzers

For users of handheld alloy analyzers, how to buy high-quality handheld alloy analyzers? This is a very important question. At the end of the article, I recommend to you a high-quality handheld alloy analyzer manufacturer — Drawell. Drawell Scientific is a professional manufacturer of handheld alloy analyzers. Always provide high-quality products to customers all over the world. They can provide excellent alloy analyzers including Handheld XRF Gold Analyzer (TrueX Gold), hand-held alloy analyzer (TrueX 800).

If you need a high-quality alloy analyzer, you are welcome to consult us, and we will recommend a suitable handheld alloy analyzer for you.