In the realm of laboratory equipment, innovation continuously shapes the way researchers conduct experiments and studies. One such innovation that has revolutionized the mixing and heating processes is the magnetic hotplate stirrer. This dual-function apparatus combines the capabilities of a hot plate and a magnetic stirrer, streamlining processes and enhancing efficiency. In this article, we delve into the essence of magnetic hotplate stirrers, understanding their mechanics, and exploring the steps to effectively utilize them in a laboratory setting.

What are the Mechanics of a Magnetic Hotplate Stirrer?

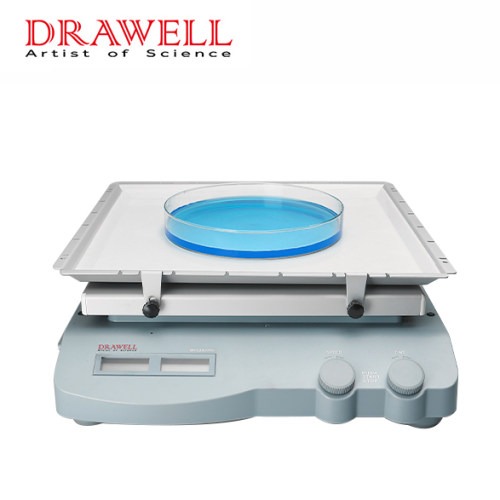

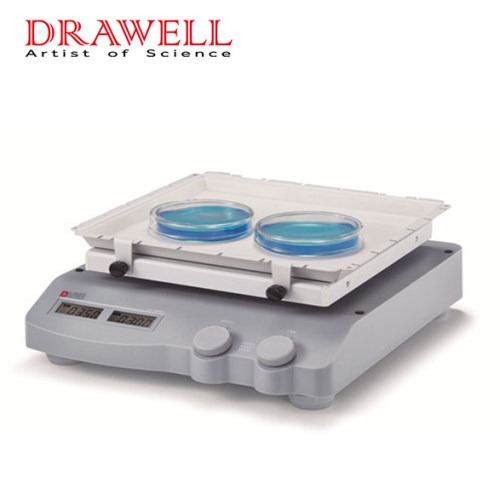

A magnetic stirrer with a hot plate is a sophisticated piece of equipment that serves as a laboratory workhorse. It offers the simultaneous functions of stirring and heating, seamlessly amalgamating two essential processes. At its core, this apparatus consists of three main components: the hot plate, a magnetic stir bar, and a magnetic field generator. The hot plate is responsible for heating the liquid or solution, the magnetic stir bar is introduced into the liquid and stirred magnetically, and the magnetic field generator beneath the hot plate drives the rotation of the stir bar.

The integration of these components presents an array of advantages. Firstly, the remote stirring facilitated by the magnetic field ensures that no mechanical parts need to be placed inside the vessel. This eliminates the risk of contamination, a concern in situations where the stirring process involves sensitive materials. Secondly, the magnetic hotplate stirrer grants precise control over stirring speed and temperature. This level of control is indispensable for experiments that demand meticulous conditions. Moreover, the dual functionality saves valuable laboratory space and minimizes the need for multiple devices, contributing to an efficient and organized workspace.

How to Use a Magnetic Hotplate Stirrer?

Utilizing a magnetic hotplate stirrer effectively requires a systematic approach. Here’s a step-by-step guide to ensure optimal performance:

- Step 1: Preparation Begin by selecting a suitable magnetic stir bar that matches the volume of the liquid to be stirred. Ensure that the stir bar material is compatible with the liquid and the intended application. Also, choose an appropriate vessel that fits comfortably on the hot plate and can accommodate the liquid.

- Step 2: Setup Place the chosen vessel onto the hot plate, ensuring it’s centered. Connect the magnetic hotplate stirrer to a power source and turn it on. Many models offer digital interfaces for easy adjustment of stirring speed and temperature. Set the desired parameters using these controls.

- Step 3: Adding the Liquid Carefully pour the liquid into the vessel. Ensure that the liquid level is sufficient to immerse the magnetic stir bar, allowing for efficient stirring. Take care not to overfill the vessel, as this could lead to spillage or hinder effective stirring.

- Step 4: Insert the Stir Bar Place the selected magnetic stir bar into the liquid. Position it in the center of the vessel to guarantee proper rotation. The magnetic field generated by the hotplate will cause the stir bar to spin, initiating the stirring process.

- Step 5: Monitoring and Adjusting As the stir bar rotates, observe the stirring action in the liquid. If necessary, adjust the stirring speed to achieve the desired mixing intensity. Simultaneously, monitor the temperature of the liquid on the hot plate, making adjustments as needed.

- Step 6: Completion and Shutdown Once the stirring process is complete, carefully remove the magnetic stir bar from the liquid. Turn off the hot plate and disconnect the power source. Allow the equipment to cool down before storing it.

Conclusion

Magnetic hotplate stirrers epitomize the convergence of scientific innovation and practicality in laboratory equipment. Their ability to combine heating and stirring functions in a single device has significantly elevated the efficiency and precision of various experiments. By understanding the core components and following a systematic approach, researchers can harness the capabilities of these devices to streamline their work and achieve consistent results. They are more accurate, efficient, and durable than other types of stirrers, and they come in a variety of sizes and features to meet the needs of different users.

When choosing a magnetic hotplate stirrer, it is important to consider the size of the vessel you will be using, the power of the stirrer, and the features you need. There are many reputable magnetic hotplate stirrer manufacturers to choose from, so be sure to do your research and compare prices before making a purchase. With proper care and maintenance, a magnetic hotplate stirrer can be a valuable asset in your laboratory for many years to come.

As laboratories continue to advance, magnetic hotplate stirrers stand as a testament to the power of ingenuity in meeting the evolving needs of scientific exploration. So, the next time you embark on an experiment, remember the magnetic hotplate stirrer – a steadfast companion in your quest for knowledge and discovery.