A biosafety cabinet (BSC) is a box-type air purification negative pressure safety device that can prevent the escape of aerosols containing dangerous or unknown biological particles during the experimental operation process. Biological safety cabinets are used to protect the operator, the laboratory environment, and experimental materials from exposure to infectious aerosols and splash when operating infectious experimental materials such as primary cultures, bacterial strains, and diagnostic specimens.

Biosafety Cabinet Application

As for biosafety cabinet application, a biosafety cabinet is widely used in scientific research, teaching, clinical testing, and production in the fields of microbiology, biomedicine, genetic engineering, and biological products. The biosafety cabinet is the basic safety protection equipment in the first-level protective barrier of laboratory biosafety.

Biosafety Cabinet Principle

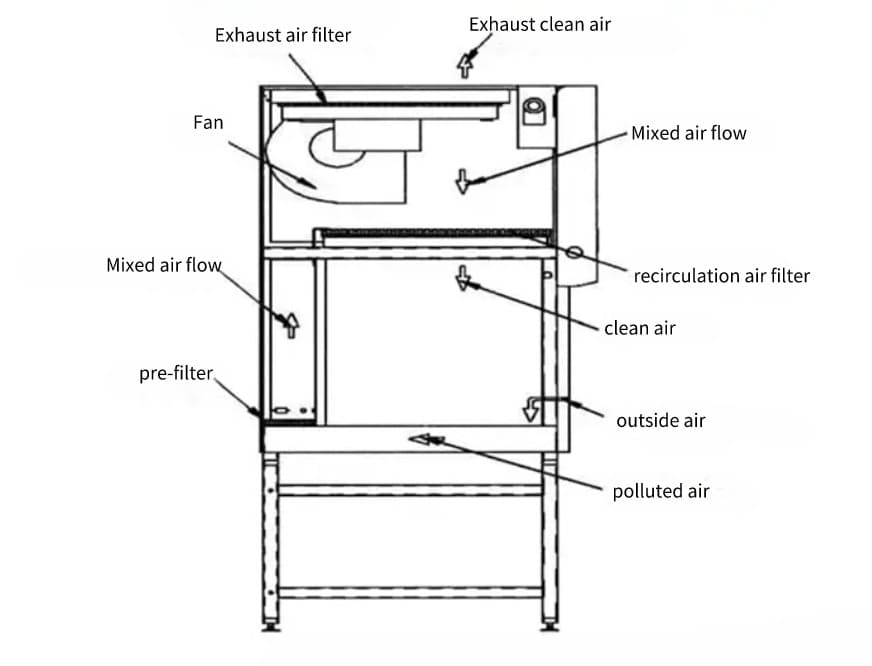

The biosafety cabinet working principle is mainly to suck the air in the biological safety cabinet outward to keep the biosafety cabinet in a negative pressure state, and to protect the staff through vertical airflow. The outside air is filtered by an air filter (high-efficiency particulate air filter, HEPA filter) and then enters the biosafety cabinet to avoid contamination of the processed samples. The air in the biological safety cabinet also needs to be filtered by a HEPA filter before being discharged into the atmosphere to protect the environment.

Biosafety Cabinet Function

After you have known the biosafety cabinet principle and application, you can know the biosafety cabinet function from this part. The main function of the safety cabinet is to prevent the operator and the environment from being exposed to the negative pressure filtration fume hood of bioaerosols generated during the experiment. The biosafety cabinet is the main equipment to prevent laboratory-acquired infection.

Biosafety Cabinet Types

According to the difference in the level of biological safety protection, biological safety cabinets can be divided into three types: first level, second level, and third level.

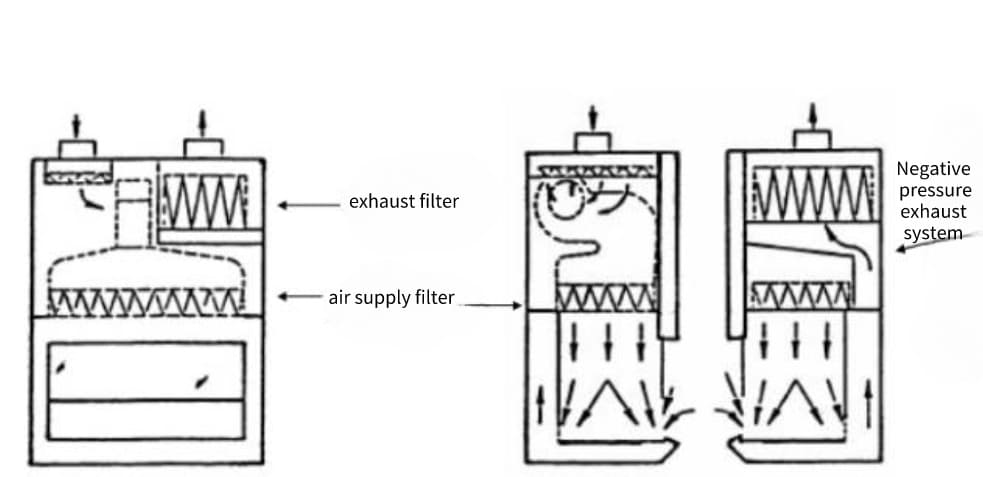

1. Class I Biosafety Cabinet

Class I biosafety cabinets protect workers and the environment without protecting samples. The airflow principle is the same as that of the laboratory general kitchen. The difference is that the exhaust port is equipped with a filter. All types of biosafety cabinets use filters on the exhaust and air inlets. The first-class biological safety cabinet has no fan itself and relies on the fan in the external ventilation pipe to drive the airflow. Since it cannot protect test objects or products, it is less used at present.

2. Class II biosafety cabinets

Class II biosafety cabinets are currently the most widely used type of biosafety cabinet. The class II biological safety cabinet can be divided into four levels according to the inlet air velocity, exhaust mode, and circulation mode: Type A1, Type A2, Type B1, and Type B2. All Class II biosafety cabinets provide protection for workers, the environment, and products. If you want to buy these types of biosafety cabinets, you can buy them from Drawell which is a biosafety cabinet manufacturer in China.

The minimum air velocity of the front window of the class II A1 biosafety cabinet or the measured average value shall be at least 0.38m/s. 70% of the air is recirculated to the work area through the HEPA filter, and 30% of the air is filtered out through the exhaust port.

The minimum air velocity of the front window of the class II A2 type biosafety cabinet or the measured average value shall be at least 0.5m/s. 70% of the air is recirculated to the work area through the HEPA filter, and 30% of the air is filtered out through the exhaust port.

Class II B-type biosafety cabinets are all safety cabinets connected to the exhaust system. The fan connected to the exhaust duct of the safety cabinet is connected to the emergency power supply. The purpose is to maintain the negative pressure of the biosafety cabinet in case of power failure, to prevent dangerous gas from leaking out of the laboratory. The minimum or measured average velocity of the front window airflow shall be at least 0.5m/s (100fpm).

70% of the gas in the class II B1 type biosafety cabinet is removed through the HEPA filter at the exhaust port, and 30% of the gas is recirculated to the working area through the HEPA filter at the gas supply port.

The class II B2-type biosafety cabinet is a 100% full-row safety cabinet without internal circulating air flow, which can provide biological and chemical safety control at the same time, and can operate volatile chemicals and volatile nuclear radiation as additives for microbial experiments.

3. Class III biosafety cabinets

Class III biosafety cabinets are designed for laboratories with a biological safety protection level of 4. The biosafety cabinet is completely airtight. The staff operates through gloves connected to the cabinet, and the test products enter and exit the safety cabinet through the double-door transfer box to ensure no contamination. The class III biosafety cabinet is suitable for high-risk biological experiments, such as experiments related to SARS and the Ebola virus.