Autoclaving is a critical sterilization process used in healthcare, laboratories, and various industrial settings to eliminate all forms of microbial life. However, not all instruments can withstand the intense heat, steam, and pressure of an autoclave. Here’s an overview of what instruments can safely go into an autoclave and those that require alternative sterilization methods.

Understanding the Functions of An Autoclave

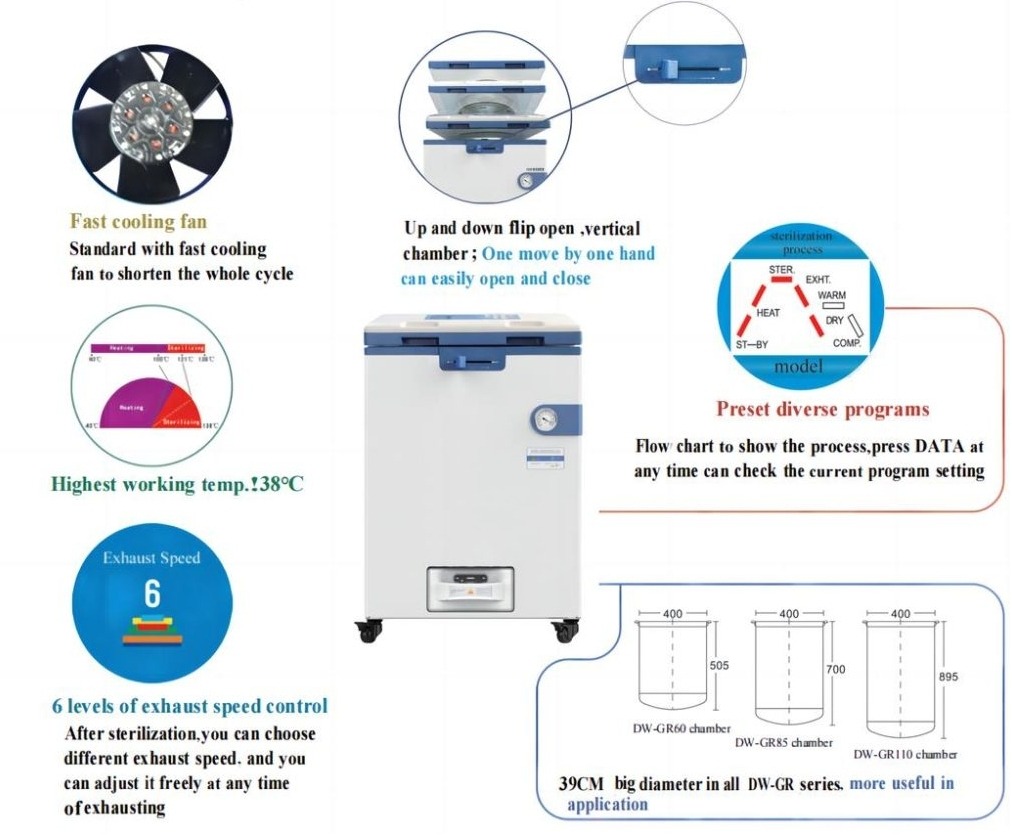

An autoclave is a specialized device used for sterilizing medical, laboratory, and industrial equipment by exposing items to high-pressure saturated steam at elevated temperatures, typically between 121-134°C (250-273°F). This process effectively eliminates bacteria, viruses, fungi, and spores, ensuring items are safe and free of any potentially harmful microorganisms. Autoclaves are widely used in healthcare, scientific research, and manufacturing, providing a reliable means of sterilization for heat-resistant tools and materials.

Instruments that Can Go into an Autoclave

1. Metal Instruments

- Examples: Scalpels, forceps, scissors, surgical clamps, retractors.

- Material Considerations: Metals like stainless steel are highly resistant to high temperatures, pressure, and moisture, making them ideal for autoclaving.

- Why It’s Suitable: Metal surgical instruments retain their structural integrity through the sterilization of an autoclave and don’t degrade or warp under the intense conditions of an autoclave, ensuring they remain sterile and usable for future procedures.

2. Glassware

- Examples: Petri dishes, test tubes, flasks, beakers (made of borosilicate glass or similar heat-resistant materials).

- Material Considerations: Only heat-resistant glass, such as Pyrex or borosilicate, should be autoclaved; standard glass can crack or shatter.

- Why It’s Suitable: Glass items that are heat-resistant can undergo autoclaving without damage, allowing for sterile containment of chemicals and samples in lab environments.

3. Autoclavable Plastics

- Examples: Polypropylene (PP), polycarbonate (PC) lab containers, sterilization pouches.

- Material Considerations: Only plastics labeled as “autoclavable” or specifically designed to handle high temperatures are suitable.

- Why It’s Suitable: Durable plastics can withstand autoclave conditions, providing lightweight, safe storage options for labs and medical settings.

4. Rubber and Silicone Items

- Examples: Autoclavable tubing, gaskets, masks.

- Material Considerations: Only certain types of rubber and silicone that are marked as autoclavable can endure the process.

- Why It’s Suitable: Autoclavable rubber and silicone items retain flexibility and do not degrade under high heat, ensuring they remain useful for medical and lab applications.

5. Textile Products

- Examples: 100% cotton gowns, surgical drapes, towels.

- Material Considerations: Natural fibers like cotton are often autoclavable, while synthetic fibers may melt or degrade.

- Why It’s Suitable: Cotton and other heat-resistant fibers can withstand autoclave conditions, making them ideal for reusable items like lab coats and towels.

6. Stainless Steel and Aluminum Trays

- Examples: Instrument trays, sterilization cassettes.

- Material Considerations: High-quality stainless steel or aluminum is suitable for autoclaving, but lower-quality metals may warp or corrode.

- Why It’s Suitable: Metal trays facilitate the easy and simultaneous sterilization of multiple instruments, maintaining their durability under autoclave conditions.

Instruments that Can’t Go into an Autoclave

1. Heat-Sensitive Instruments

- Examples: Endoscopes, certain surgical cameras, electronic medical devices.

- Material Considerations: Delicate electronics and fiber optics are damaged by steam and high temperatures.

- Alternative Methods: Low-temperature hydrogen peroxide plasma sterilization or ethylene oxide (EO) gas sterilization are safer options that prevent heat-related damage.

2. Certain Plastics

- Examples: Polyethylene (PE), polystyrene (PS), and acrylonitrile butadiene styrene (ABS) containers.

- Material Considerations: These plastics have low melting points and deform or release toxic fumes under high heat.

- Alternative Methods: Chemical disinfectants or EO gas sterilization are better suited to these heat-sensitive plastics.

3. Natural Fibers or Non-Heat-Resistant Fabrics

- Examples: Nylon, polyester, and other synthetic textiles.

- Material Considerations: Synthetic fabrics may melt or degrade, and certain coatings on fabrics may release harmful chemicals.

- Alternative Methods: UV sterilization or chemical disinfectants are often safer for synthetic fibers.

4. Wooden Instruments

- Examples: Tongue depressors, wooden splints.

- Material Considerations: Wood can absorb moisture, swell, and crack in an autoclave, making it unsuitable for steam sterilization.

- Alternative Methods: Disposable options or sanitization via chemical disinfectants can be used for wooden instruments.

5. Powdered or Liquid Solutions

- Examples: Saline solutions, powdered reagents, certain lab chemicals.

- Material Considerations: Liquids can boil over or spill, and powders may aerosolize, posing a risk to the sterilization process.

- Alternative Methods: Pre-sterilized solutions or careful sterilization of the containers alone before adding powders or liquids.

6. Sharp Instruments Prone to Rusting or Dulling

- Examples: Carbon steel scalpels, razor blades.

- Material Considerations: Carbon steel can rust or become dull after repeated autoclaving.

- Alternative Methods: Single-use sterile instruments or ethylene oxide gas sterilization can maintain blade integrity.

Best Practices for Using an Autoclave

| Best Practices for Using an Autoclave | Details |

| 1. Pre-Clean Instruments | Rinse or wipe down instruments to remove any debris or residue before autoclaving to ensure effective sterilization. |

| 2. Check Compatibility | Confirm that each item can withstand autoclave temperatures and pressure; avoid heat-sensitive materials. |

| 3. Use Proper Packaging | Place items in autoclave-safe bags, wraps, or containers to prevent contamination and ensure complete sterilization. |

| 4. Arrange Items for Steam Flow | Avoid overcrowding; arrange items to allow steam circulation around each item, ensuring thorough sterilization. |

| 5. Set Appropriate Time and Temperature | Follow recommended autoclave settings for specific materials and load types, usually 121-134°C for 15-20 minutes. |

| 6. Avoid Overloading the Autoclave | Leave sufficient space between items to allow for steam penetration and efficient heat transfer, reducing the risk of incomplete sterilization. |

| 7. Use Vented Lids for Liquids | Use vented or loose-fitting lids on liquids in an autoclave to avoid spills and allow safe steam contact. |

| 8. Monitor the Process | Regularly check the autoclave’s temperature, pressure, and cycle times to ensure they align with recommended levels for effective sterilization. |

| 9. Allow for Cooling Time | After the cycle, wait for the pressure to normalize and items to cool down before removing them from the autoclave to prevent burns and damage. |

| 10. Regularly Maintain and Calibrate | Perform routine maintenance checks on seals, valves, and heating elements, and calibrate the autoclave periodically for consistent performance. |

| 11. Conduct Biological Monitoring | Use spore tests regularly to verify that the autoclave is killing microbial life effectively, ensuring compliance with sterilization standards. |

| 12. Log Each Autoclave Cycle | Record cycle details like time, temperature, and pressure for traceability and quality assurance in case of contamination or equipment failure. |

In summary, understanding which instruments can and cannot go into an autoclave is essential for maintaining safe, effective sterilization practices. Autoclaving compatible items such as stainless steel instruments, heat-resistant glassware, metal surgical instruments, etc, help facilitate rigorous sanitation while preserving item integrity. In contrast, heat-sensitive items, specific plastics, wooden instruments and materials that could melt or degrade must be handled using alternative sterilization methods to prevent damage and contamination. Proper selection and handling of items for autoclaving can significantly enhance operational efficiency and safety in any facility.