Conductivity meters are instruments used to measure the ability of a liquid to conduct electricity. They provide valuable insights into the conductivity of a solution, which is a key indicator of its chemical composition and overall quality. This ability making conductivity meter a valuable tool for various applications, including water quality monitoring, hydroponics, and chemical analysis. In this article, we will delve into the different types of conductivity meters, their basic principles, and factors to consider when selecting the most suitable meter for specific applications.

Principles of Conductivity Measurement

Conductivity is a measure of a solution’s ability to conduct electric current. It depends on the concentration of ions present in the solution. When an electric field is applied to a conductive solution, ions move towards oppositely charged electrodes, resulting in the flow of electric current. The conductivity of the solution is directly proportional to the concentration of ions and their mobility. Conductivity meters measure this electrical conductivity to determine the solution’s properties.

Types of Conductivity Meters

A. Based on Measurement Method:

Contact Conductivity Meters: Contact conductivity meters, also known as direct or electrode conductivity meters, measure the conductivity of a solution by directly immersing electrodes into the sample. These meters typically consist of two electrodes, usually made of metal, which come into direct contact with the solution. The conductivity is determined by measuring the electrical resistance between the electrodes. The greater the conductivity of the solution, the lower the resistance, and vice versa. Contact conductivity meters are commonly used for laboratory applications where precise measurements are required.

Inductive Conductivity Meters: Inductive conductivity meters utilize electromagnetic induction to measure the conductivity of a solution. Instead of directly contacting the solution with electrodes, these meters induce an alternating electrical current into the solution, generating a voltage proportional to the solution’s conductivity. This voltage is then measured and used to calculate the conductivity. Inductive conductivity meters are often preferred for industrial applications where the solution may contain particles or be too corrosive for direct contact methods.

B. Based on Instrument Design:

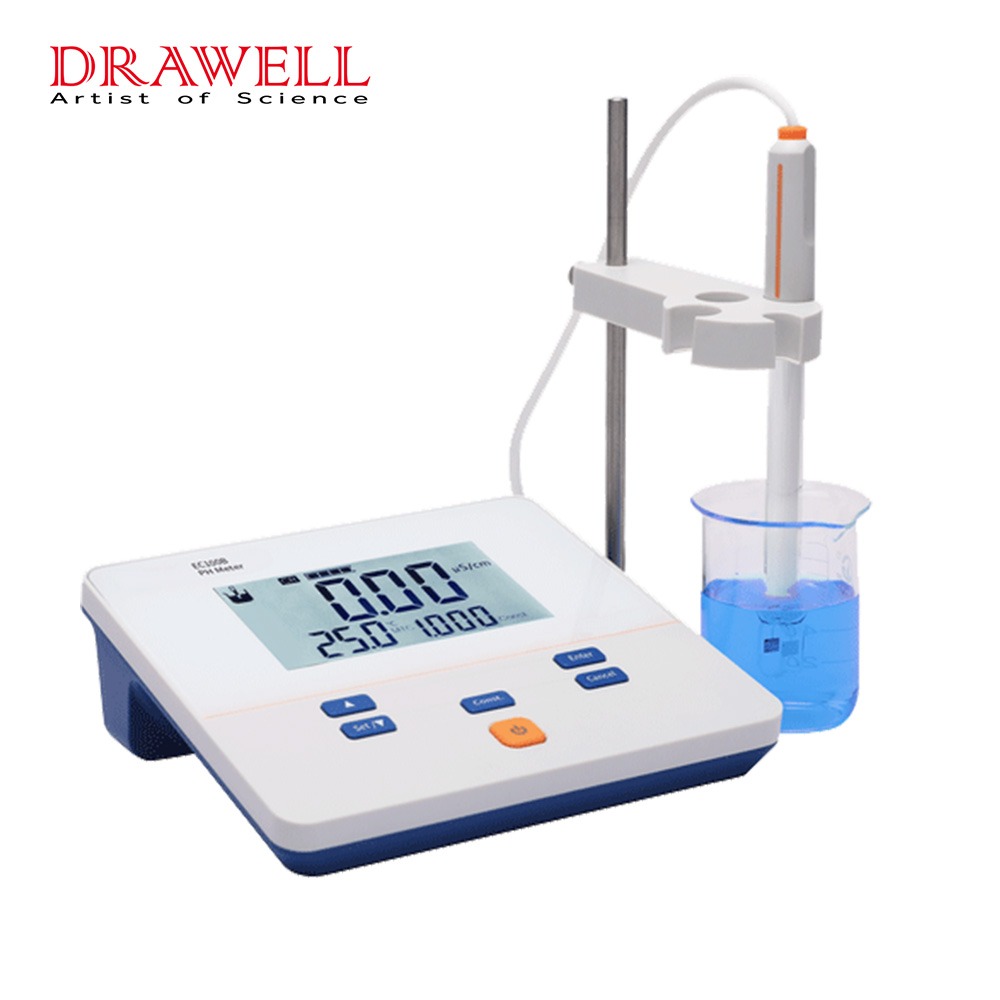

Benchtop Conductivity Meters: Benchtop conductivity meters are larger, stationary instruments designed for use in laboratory settings. They typically feature a stable platform with a clear display and user-friendly controls for precise measurement and data analysis. Benchtop meters are suitable for applications requiring high accuracy and repeatability, such as scientific research, quality control, and educational purposes.

Portable Conductivity Meters: Portable conductivity meters are compact and lightweight instruments designed for on-the-go measurements in various field settings. These meters are battery-powered and often feature rugged construction to withstand harsh environmental conditions. Portable meters offer convenience and flexibility for applications such as environmental monitoring, water quality analysis, and on-site testing in industries like agriculture, food processing, and wastewater treatment.

Pocket Conductivity Meters: Pocket conductivity meters, also known as pen or handheld conductivity meters, are the smallest and most portable type of conductivity meter. They are designed to fit easily into a pocket or tool belt for quick and convenient measurements. Pocket meters typically have simplified controls and a compact display, making them ideal for simple conductivity measurements in situations where space and mobility are limited. They are commonly used by field technicians, inspectors, and hobbyists for quick spot checks and basic testing needs.

Each type of conductivity meter has its own advantages and limitations, making it important to choose the most suitable instrument based on the specific requirements of the application.

Comparison of Different Designs of Conductivity Meters

| Feature | Benchtop Conductivity Meters | Portable Conductivity Meters | Pocket Conductivity Meters |

| Size | Larger | Compact | Very Small |

| Mobility | Stationary | Portable | Highly Portable |

| Power Source | Mains power | Battery | Battery |

| Display and Controls | Clear display and user-friendly controls | Typically have a smaller display and simplified controls | Simplified controls and compact display |

| Environmental Resistance | Suitable for controlled laboratory environments | Rugged construction for field use; withstands harsh environmental conditions | Rugged construction for field use; withstands harsh environmental conditions |

| Cost | High | Moderate | Low to Moderate |

This table offers a concise comparison of the key features and characteristics of different types of conductivity meters based on their instrument design, aiding users in selecting the most suitable option for their specific needs and requirements.

Factors to Consider When Choosing a Conductivity Meter

When selecting a conductivity meter, several factors should be considered to ensure that the chosen instrument meets your specific requirements and applications. Here are the key factors to consider:

Measurement Range and Accuracy: Determine the range of conductivity values you need to measure and ensure that the meter offers sufficient accuracy and precision within that range. Consider whether you require high-precision measurements for laboratory analysis or broader ranges suitable for field applications.

Measurement Method: Choose between contact and inductive conductivity meters based on your application needs. Contact meters provide direct immersion of electrodes into the solution and are suitable for precise laboratory measurements, while inductive meters offer non-contact measurements and are preferable for industrial applications or solutions with particles.

Instrument Design: Consider the instrument’s design in terms of portability and size. Decide whether you need a benchtop meter for stationary laboratory use, a portable meter for field measurements, or a pocket-sized meter for quick spot checks.

Ease of Use: Look for meters with user-friendly interfaces, intuitive controls, and clear displays to facilitate easy operation and accurate readings. Consider whether you need advanced features such as data logging, calibration options, or automatic temperature compensation.

Environmental Conditions: Assess the environmental conditions in which the conductivity meter will be used. Choose a meter with appropriate environmental resistance, such as rugged construction and waterproofing, if it will be exposed to harsh conditions or used outdoors.

Power Source: Determine whether the meter requires mains power or operates on batteries. Battery-powered meters offer greater portability but may require frequent battery replacement or recharging.

Calibration and Maintenance: Consider the ease of calibration and maintenance requirements of the conductivity meter. Look for meters with simple calibration procedures and readily available calibration standards. Additionally, assess the availability of spare parts and technical support for maintenance and repairs.

Budget: Set a budget based on your requirements and consider the cost-effectiveness of different conductivity meters. Balance the features and performance you need with the available budget to make a cost-effective choice.

By carefully evaluating these factors, you can select the most suitable conductivity meter for your specific applications, ensuring accurate measurements and efficient operation.

Conclusion

Conductivity meters play a vital role in various industries and scientific research fields by providing accurate measurements of solution conductivity. Understanding the different types of conductivity meters, their basic principles, and factors influencing their selection is crucial for achieving reliable and precise results in conductivity measurement applications. By considering these aspects, users can choose the most appropriate conductivity meter to meet their specific requirements and optimize their processes and experiments. If you a looking for a conductivity meter supplier, please feel free to conatct Drawell.