Many people don’t understand the difference between biosafety cabinet and ultra-clean workbench, thinking that the two have similar uses. There are many misunderstandings. There are still many differences between an ultra-clean workbench and a biosafety cabinet. This article will introduce the difference between them in principle and use.

The Difference Between Biosafety Cabinet And Clean Bench In Working Principle

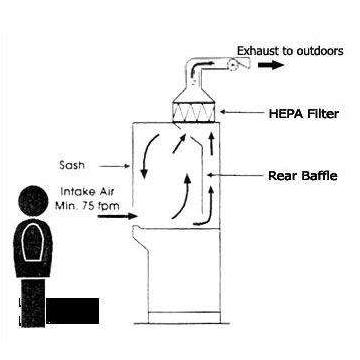

Working principle of biosafety cabinet

First of all, this part will define the two in principle. The biosafety cabinet is a negative pressure purification workbench, which can prevent the operator and the environment from being exposed to harmful aerosols generated during the laboratory process. It is a cage for infectious microorganisms. Correct operation of the biosafety cabinet can completely protect the operator and samples, and the working environment.

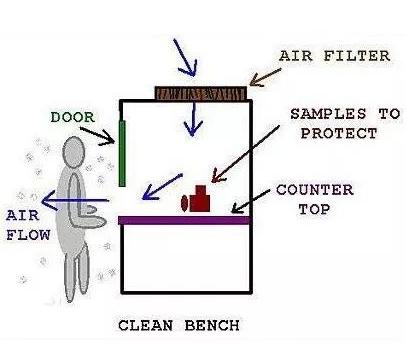

Working principle of clean bench

The working principle of the ultra-clean workbench is to blow the purified air through the high-efficiency filter downward or horizontally through the work area to protect the samples. Since the work area is a positive pressure area, the airflow overflows through the operation window to only protect the samples, while the operators and the environment are not protected. If the operation contains any known or potential pathogenic aerosols, it will bring great danger to the operator.

The Differences While Using Biosafety Cabinet and Clean Bench

Special requirements for using a biosafety cabinet

- Do not place objects and materials on window grilles. Cleaned, used, and virus-containing items should be placed separately. Keep unclean items away from openings as much as possible.

- Operators should try their best to wear long-sleeved threaded cuff work clothes and rubber gloves, and at least wash their hands with an antiseptic soap before and after work.

- Minimize the crossing of airflow in front of the window as much as possible. You can put all the items you need into the biosafety cabinet in an orderly manner before starting the machine, to reduce unnecessary entry and exit of arms.

- After preparation, the fan runs for 2-3 minutes to fully purify the air in the biosafety cabinet.

- The tightness of the biosafety cabinet should be tested according to the frequency of use, generally not less than twice a year.

Special requirements for using ultra-clean workbenches

- Before starting the experiment, let the fan run for at least 5 minutes.

- The ultra-clean bench does not protect the operator, so the operation of pathogenic bacteria and microbial agents that may cause harm to the human body should not be performed. The operator should keep in mind the airflow direction to prevent unsafe factors.

The biosafety cabinet is negative pressure. The air enters the machine from the external environment through the glass front window, and then the air flows upward and is discharged after passing through the high efficiency. Some are fully exhausted, and some are partially circulated. The ultra-clean workbench is positive pressure, and the clean air after high-efficiency filtration is blown from top to bottom, or blown horizontally, and finally enters the environment through the glass window. Which one is better? It depends on your requirement. In a word, the more applicable the better. If you want to buy biosafety cabinets, you can visit our website to know more. Drawell is a reliable biosafety cabinet manufacturer that you can trust.