Density is a fundamental physical property defined as mass per unit volume (typically expressed in units such as g/cm³ or kg/m³). It is a critical parameter in various scientific and industrial applications, including material characterization, quality control, and research. Accurate density measurement is essential in understanding the properties of solids, liquids, and gases. Laboratories rely on various instruments to measure density, depending on the nature of the sample and the required precision. Here we explores the principles behind density measurement, the types of instruments used, and their applications in laboratory settings.

Principles of Density Measurement

Density measurement is based on determining the relationship between the mass and volume of a sample. Mathematically, density (ρ) is expressed as:

ρ = Mass (m) / Volume (V)

Mass Measurement: Determined using precise balances or scales, ensuring accuracy to an appropriate number of decimal places.

Volume Determination: The volume of a sample can be measured directly (e.g., with volumetric containers) or indirectly (e.g., using displacement methods or specialized devices).

Methods of Density Measurement:

- Direct Measurement: Suitable for simple cases where both mass and volume are easily measurable.

- Archimedes’ Principle: Based on buoyancy, where the volume of a sample is determined by the amount of fluid it displaces.

- Oscillatory Techniques: Used in advanced digital density meters, measuring changes in oscillation frequency caused by the sample’s density.

The choice of principle depends on the sample type (solid, liquid, gas) and the desired precision. So, let get to know the density measurement instruments based on these principles.

Types of Density Measurement Instruments

Density measurement instruments vary widely based on the sample’s physical state and the precision requirements. Here we list some common instruments:

A. For Solids

Pycnometers: A pycnometer is a glass container with a precisely measured volume. The sample’s mass is measured, and its volume is determined by the liquid it displaces.

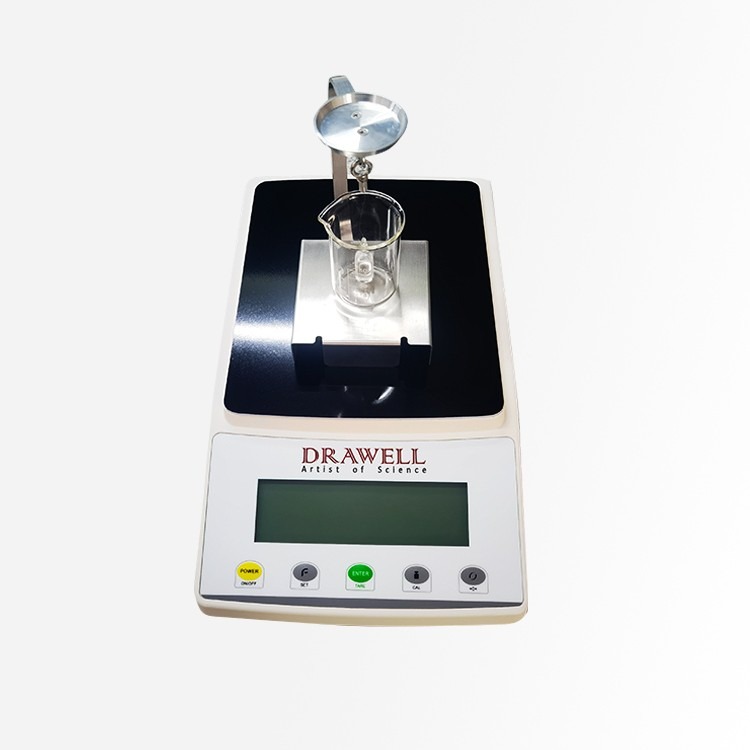

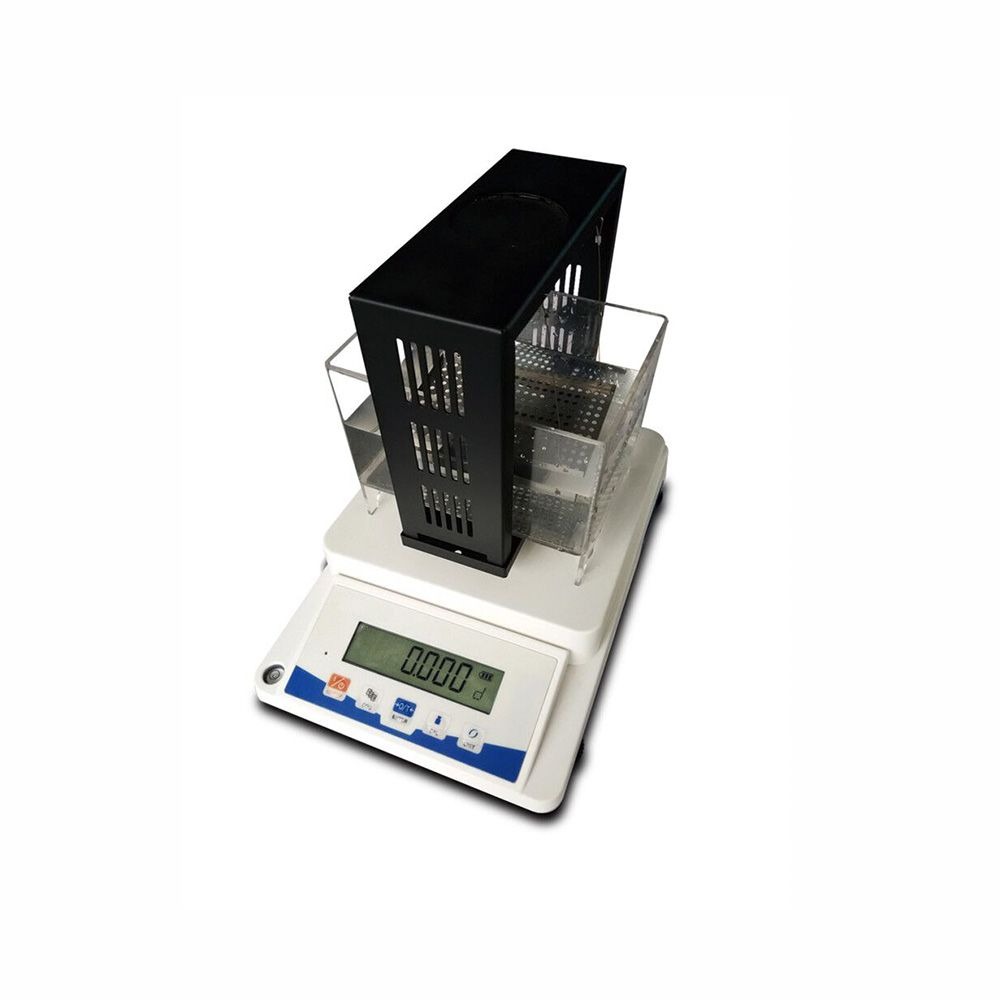

Density Determination Kits (Archimedes Principle): Used with balances, these kits measure density based on buoyancy when the solid is submerged in a liquid.

| Instruments for Solids | Description | Applications | Precision |

| Pycnometers | Glass containers with precise volumes used to determine density via displacement. | Powdered and granular solids. | High |

| Density Determination Kits | Kits based on Archimedes’ Principle; measure buoyancy in a liquid. | Irregularly shaped solids. | Moderate to high |

B. For Liquids

Hydrometers: A simple device that floats in the liquid, with the depth of immersion indicating density.

Digital Density Meters: Automated devices based on oscillating U-tube technology.

Pycnometers for Liquids: Glass containers used to measure the density of liquids by determining their mass and volume.

| Instruments for Liquids | Description | Applications | Precision |

| Hydrometers | Floating devices; immersion depth indicates density. | Beverages, petroleum products. | Moderate |

| Digital Density Meters | Automated devices using oscillating U-tube technology. | Precise density measurements of liquids. | Very high |

| Pycnometers | Glass containers for liquid density measurement by mass and volume determination. | Research labs. | High |

C. For Gases

Gas Pycnometers: Instruments that determine gas density by measuring pressure changes in a known volume.

Ultrasonic Density Meters: Measure the density of gases by analyzing the speed of sound through the sample.

| Instruments for Gases | Description | Applications | Precision |

| Gas Pycnometers | Instruments measuring pressure changes in a known volume to calculate density. | Material science and gas research. | Very high |

| Ultrasonic Density Meters | Measure gas density by analyzing sound speed through the sample. | Specialized industrial and research settings. | High |

For routine measurements, graduated cylinders, top-loading balances, and simple hydrometers are often used for routine density measurements where high accuracy is not critical.

For high-precision measurements, analytical balances, pycnometers, digital densitometers, and gas pycnometers are used for high-precision density measurements required in research and quality control applications.

These instruments are tailored to meet the diverse needs of laboratory applications, ensuring reliable and accurate density measurements. By selecting the right tool for the sample type and required precision, researchers and technicians can achieve optimal results.

Factors to Consider When Choosing a Density Measurement Instrument

Selecting the appropriate density measurement instrument is essential for achieving accurate and reliable results. Here are the key factors to consider:

- Sample Type

Determine whether the sample is a solid, liquid, or gas.

Choose instruments designed specifically for the physical state of the material (e.g., pycnometers for solids, digital density meters for liquids).

- Required Precision and Accuracy

High-precision applications (e.g., pharmaceutical or chemical industries) may require advanced instruments like digital density meters.

Moderate precision needs can often be met with simpler tools like hydrometers or Archimedes-based kits.

- Volume of Sample

For small samples, use instruments that require minimal material, such as micro-pycnometers.

For large volumes, ensure the instrument can accommodate the sample size.

- Ease of Use

Consider whether the instrument is manual or automated.

Digital instruments often provide faster results with less user intervention.

- Budget Constraints

Basic instruments like hydrometers are cost-effective for general applications.

Advanced instruments like oscillating U-tube density meters involve higher costs but deliver superior accuracy.

- Environmental Conditions

Ensure the instrument can function under specific environmental conditions, such as temperature or pressure variations.

For gases, instruments like ultrasonic meters may require controlled environments.

- Sample Properties

Consider sample-specific factors such as viscosity, corrosiveness, or reactivity.

Select materials for the instrument that are compatible with the sample to avoid damage or contamination.

By carefully evaluating these factors, laboratories can select the most suitable density measurement instrument to meet their specific needs and ensure high-quality results.

Applications of Density Measurement in Labs

Density measurement is indispensable in various scientific and industrial fields. Key applications such as:

Chemical Analysis:

- Determining the concentration of solutions (e.g., molarity, molality).

- Identifying unknown substances based on their density.

- Monitoring the progress of chemical reactions.

Materials Characterization:

- Assessing the quality and purity of materials.

- Determining the composition of alloys and other materials.

- Investigating the microstructure of materials.

Pharmaceutical Research:

- Ensuring the quality and purity of drugs.

- Optimizing drug formulations and dosage.

- Conducting stability studies on pharmaceuticals.

Environmental Monitoring:

- Analyzing water and soil samples for pollutants.

- Monitoring the quality of air and other environmental factors.

Food Science:

- Monitoring the quality and consistency of food products.

- Detecting adulteration in food.

- Optimizing food processing techniques.

Density measurement is a vital process across various scientific disciplines and industries, providing insights into the physical properties of materials. The choice of instrument depends on the type of sample (solid, liquid, gas) and the required precision. Instruments like pycnometers, hydrometers, and digital density meters have unique features tailored to specific applications. By understanding the principles and selecting the appropriate tools, laboratories can achieve accurate and reliable density measurements, ensuring the success of their research and quality control processes. Want to know more about digital density meters, please feel free to contact us.