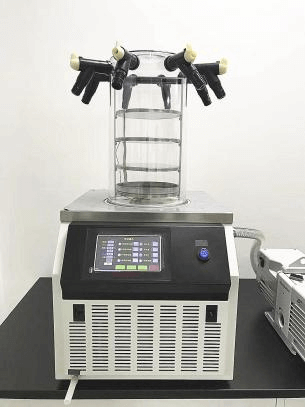

In the ever-evolving landscape of pharmaceuticals, the quest to improve drug stability, extend shelf life, and enhance the quality of sensitive pharmaceutical products is unceasing. One remarkable technology that has revolutionized the industry is freeze-drying. In this article, we will delve into the intricacies of freeze drying, explore the benefits it offers for pharmaceutical applications, and focus on the pivotal role of lab freeze dryers in achieving these objectives.

What is Freeze Drying?

Freeze drying, also known as lyophilization, is a dehydration process that removes water from a product by freezing it and then sublimating the ice under a vacuum. Freeze drying is a gentle process that preserves the physical structure and biological activity of sensitive products, such as vaccines, proteins, and antibodies.

Freeze drying is a valuable tool in the pharmaceutical industry. It is used in research and development, clinical trials, and manufacturing to produce high-quality, stable pharmaceutical products with extended shelf lives.

Benefits of Using a Lab Freeze Dryer for Pharmaceutical Applications

There are many benefits to using a lab freeze dryer for pharmaceutical applications. Some of the key benefits include:

- Extend shelf life: Freeze drying can significantly extend the shelf life of pharmaceutical products. Freeze-dried products can be stored at room temperature for many years without losing their potency or stability. This makes freeze-drying an ideal process for preserving temperature-sensitive products and for products that need to be transported long distances.

- Preserve biological activity: Freeze drying is a gentle process that preserves the biological activity of sensitive pharmaceutical products. This is because the freezing and sublimation process does not damage the structure of the product. This makes freeze-drying an ideal process for preserving vaccines, proteins, and antibodies, which are all highly sensitive to heat and other forms of stress.

- Improve product quality: Freeze drying can improve the quality of pharmaceutical products by reducing their moisture content and making them less susceptible to degradation. Freeze-dried products are also typically more soluble and reconstitute more quickly than liquid or frozen products.

- Enhance physical properties: Freeze drying can also enhance the physical properties of pharmaceutical products. For example, freeze-dried products are often more lightweight and have a longer shelf life than liquid or frozen products. This makes them easier to transport and store.

Applications of Lab Freeze Dryers in the Pharmaceutical Industry

Lab freeze dryers are used in a variety of pharmaceutical applications, including:

- Research and development: Lab freeze dryers are used in pharmaceutical research and development to develop and test new drugs and formulations. Freeze drying is used to preserve the stability of new drug candidates and to produce small batches of drugs for preclinical testing and clinical trials.

- Clinical trials: Lab freeze dryers are also used in clinical trials to produce investigational drugs for testing in human subjects. Freeze-dried drugs are typically more stable and easier to administer than liquid or frozen drugs. This makes them ideal for use in clinical trials, which often involve multiple doses and long-term follow-up.

- Manufacturing: Lab freeze dryers are also used in pharmaceutical manufacturing to produce small batches of drugs for clinical trials and commercialization. Freeze drying is a versatile process that can be used to produce a wide variety of pharmaceutical products, including vaccines, proteins, antibodies, and small-molecule drugs.

Conclusion

Lab freeze dryers are an essential tool in the pharmaceutical industry. They are used in research and development, clinical trials, and manufacturing to produce high-quality, stable pharmaceutical products with extended shelf lives. Freeze drying is a gentle process that preserves the physical structure and biological activity of sensitive products, making it an ideal process for a wide variety of pharmaceutical applications.