Centrifuges are indispensable tools in laboratories, playing a crucial role in various processes, from separating blood components to purifying cellular materials. However, like all precision instruments, centrifuges require regular care and maintenance to function correctly. Unfortunately, many labs overlook key aspects of centrifuge upkeep, leading to equipment failures, compromised results, and even safety hazards. Here we will highlight common centrifuge maintenance mistakes and provide best practices for preventing them. By understanding these critical points, laboratories can optimize centrifuge performance, enhance safety, and extend equipment lifespan.

Common Mistakes in Centrifuge Maintenance

Centrifuges are precision instruments that require careful handling and maintenance. Overlooking essential care steps can lead to various problems, from reduced efficiency to equipment damage.

Mistake 1: Skipping Routine Inspections

Routine inspections are the backbone of effective centrifuge maintenance, yet they are often neglected due to time constraints or a lack of awareness. Skipping these inspections can lead to the unnoticed deterioration of components, which can ultimately cause significant damage to the machine and affect its performance.

Solution: Implement a regular inspection schedule, ensuring that all moving parts, seals, and electrical connections are checked. Pay attention to unusual sounds or vibrations during operation, which can indicate underlying issues.

Mistake 2: Ignoring Manufacturer Guidelines

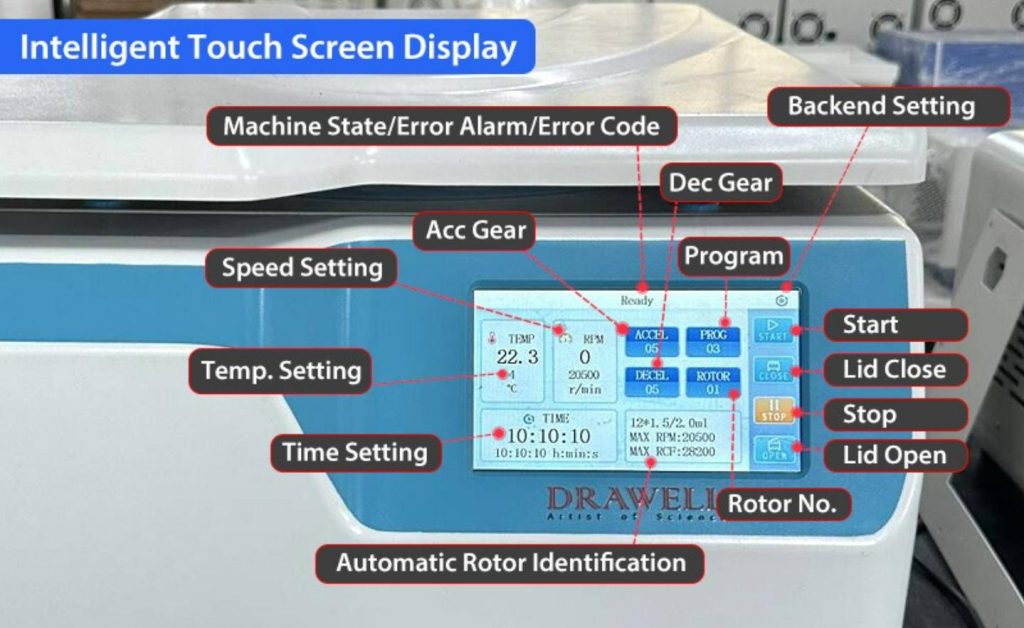

Every centrifuge comes with a manufacturer’s manual that outlines specific maintenance procedures tailored to the machine’s design. Ignoring these guidelines can lead to improper handling, resulting in damage or reduced efficiency.

Solution: Always follow the manufacturer’s recommendations for maintenance intervals, cleaning agents, and operational procedures. Keep the manual accessible and ensure all lab personnel are familiar with its contents. If you still cannot work it well, feel free to contact them.

Mistake 3: Overloading the Centrifuge

Overloading is a common mistake that can cause significant harm to a centrifuge. Exceeding the weight limit or improperly balancing the load can strain the rotor and other critical components, leading to premature wear and potential failure.

Solution: Always balance the load according to the centrifuge’s specifications. Use a balance scale if necessary, and ensure that the weight is evenly distributed.

Mistake 4: Neglecting Regular Cleaning

A dirty centrifuge is not just unsightly—it can also harbor contaminants that compromise the integrity of your samples and lead to mechanical issues. Neglecting regular cleaning can result in clogged vents, corroded parts, and an overall decline in performance.

Solution: Establish a cleaning routine that includes wiping down the rotor, bucket, and chamber after each use. Use the appropriate cleaning agents recommended by the manufacturer, and avoid harsh chemicals that could damage the equipment.

Mistake 5: Using the Wrong Cleaning Agents

Using incorrect cleaning agents is another common mistake that can damage centrifuge components, particularly those made from sensitive materials like aluminum or specialized plastics.

Solution: Refer to the manufacturer’s guidelines for recommended cleaning agents. Typically, a mild detergent or alcohol-based cleaner is safe, but always verify to avoid unintended damage.

Mistake 6: Failing to Calibrate Regularly

Calibration ensures that your centrifuge operates within the correct parameters, providing accurate and reliable results. Failure to calibrate regularly can lead to discrepancies in your data and potentially ruin experiments.

Solution: Schedule regular calibration sessions, either in-house or with a certified service provider, depending on the centrifuge model. Keep detailed records of calibration dates and outcomes.

Avoiding these common mistakes is crucial for maintaining the longevity and efficiency of your centrifuge. By adhering to a regular maintenance routine and paying attention to manufacturer guidelines, you can prevent most issues before they start, ensuring your centrifuge remains a reliable tool in your lab.

Best Practices for Preventive Maintenance

Preventive maintenance is key to ensuring optimal centrifuge performance and extending equipment life. By following these best practices, laboratories can avoid costly repairs and downtime.

1. Developing a Maintenance Schedule

A well-planned maintenance schedule is key to keeping your centrifuge in top condition. Create a detailed maintenance schedule that includes daily, weekly, and monthly tasks. Daily tasks might include wiping down the machine, while weekly tasks could involve checking rotor balance, and monthly tasks might include more thorough inspections and calibration checks. Regular maintenance prevents unexpected breakdowns and extends the life of the equipment.

2. Training Laboratory Staff

Provide comprehensive training for all lab personnel who will be using the centrifuge. This should include not only operational training but also instruction on routine maintenance tasks and the importance of following the manufacturer’s guidelines. Investing in staff training can significantly reduce the likelihood of maintenance errors and extend the lifespan of your centrifuge.

3. Documentation and Record-Keeping

Maintain a logbook for each centrifuge, noting the dates and details of all inspections, cleanings, calibrations, and repairs. This log should be easily accessible to all relevant personnel. Proper documentation not only helps in tracking maintenance but also provides a legal record in case of equipment failure, ensuring accountability and compliance with lab standards.

Implementing best practices for preventive maintenance is an investment in the reliability and longevity of your centrifuge. By scheduling regular upkeep, training staff, and keeping detailed records, you can ensure that your centrifuge remains a dependable asset in your laboratory.

Troubleshooting Common Centrifuge Issues

Despite proper maintenance, issues can arise. Understanding common centrifuge problems and their solutions can help minimize downtime and prevent further damage.

Issue 1: Excessive Vibration

Check rotor balance.

Ensure proper load distribution.

Inspect for loose components.

Issue 2: Overheating

Check for blocked ventilation.

Verify rotor speed and load.

Inspect the motor for signs of wear.

Issue 3: Noise

Check for loose components.

Inspect the motor for wear.

Verify rotor balance.

Issue 4: Inefficient Separation

Check rotor speed and time settings.

Ensure proper sample preparation.

Verify rotor condition.

Promptly addressing centrifuge issues is crucial for maintaining optimal performance. By following these troubleshooting steps and consulting the manufacturer’s manual, laboratories can effectively resolve common problems.

Conclusion

Maintaining a centrifuge requires diligence and attention to detail, but the rewards—reliable performance, accurate results, and extended equipment life—are well worth the effort. By avoiding common mistakes, following best practices for preventive maintenance, and being prepared to troubleshoot issues as they arise, you can ensure that your centrifuge remains a reliable tool in your laboratory’s arsenal. Regular care and a proactive approach will not only protect your investment but also contribute to the overall efficiency and safety of your lab.