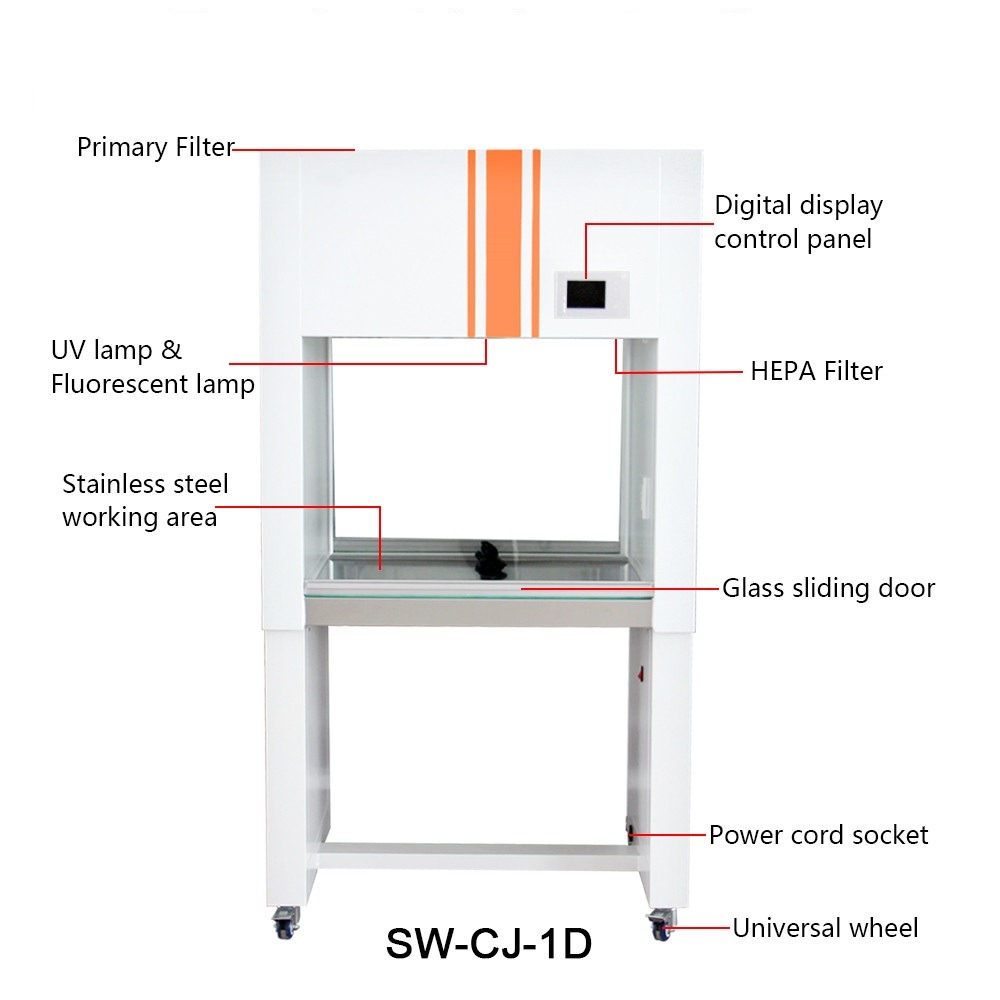

Vertical Laminar Flow Cabinet SW-CJ-1D

The air is inhaled through the fan and then filtered by the HEPA filter through the static pressure box. After that, the filtered clean air is sent out in the state of vertical or horizontal airflow, so that the operation area continues to reach 100-level cleanliness under the control of clean air and to ensure the production of environmental cleanliness requirements.

Application Range

The vertical flow clean bench is noisier than the horizontal clean bench because its fan is installed at the top. The wind blows vertically so it is often used in medical engineering to ensure the operator’s health.

Vertical laminar flow clean bench is widely used in areas requiring partial cleaning, laboratories, biopharmaceuticals, optoelectronics, microelectronics, hard disk manufacturing, and other fields.

Characteristics

- Adopting arbitrary positioning sliding door system.

- The shell is welded by cold-rolled plates, the surface is electrostatically sprayed, and the work surface is SUS304 brushed stainless steel, which is corrosion-resistant and easy to clean.

- Digital display LCD control interface, more user-friendly design.

- The vertical quasi-closed table top and the formation of a downward flow air curtain in the operation room can effectively prevent the input of external air and the operation area is clean.

- Equipped with HEPA filter, with primary filter for preliminary filtration, which can effectively extend the service life of the HEPA filter life span.

Technical Parameters

|

Model |

SW-CJ-1D |

|

Clean grade |

Grade 100(209 E U.S. Federal) |

|

Number of bacteria |

≤ 0.5 per utensil.hour(90mm utensil) |

|

Noise |

≤62dB |

|

Power |

220V/50HZ |

|

wind speed |

0.25-0.45m/s (fast and slow 2 speeds) |

|

illumination |

≥300LX |

|

Working area dimension(W*D*H) |

700×550×580mm |

|

Overall dimension(W*D*H) |

860×590×1600mm |

|

HEPA filter size and quantity |

685×455×50×① |

|

Fluorescent/UV lamp specifications and quantity |

12W×① 20W×① |

|

Operator |

one person |