Selection of melting point meter: There are many kinds and brands of melting point meters in the current market. How select a suitable melting point meter can refer to the following aspects:

1. Test Conditions of Samples

The melting point meter based on the capillary melting point measurement method can be used for powder samples, and the visual melting point instrument or automatic melting point meter can be determined according to specific indicators such as whether the sample is transparent after melting, the initial melting of the sample, and the melting range. For sheet or block samples, a micro melting point meter can be used.

2. Test Accuracy, Repeatability of Test Results, and Test Range Are the Reference for Selecting a Melting Point Meter

According to the actual needs, the higher the accuracy and repeatability, the better after meeting the measurement range.

3. Verification of Melting Point Meter

The melting point meter needs to be verified when it is turned on for use or has been used for one year. Due to the large error caused by long-term use and seasonal temperature difference, the verification is also performed once a year. The reference materials commonly used in the calibration of melting point meter are naphthalene (final melting 80.6 ℃), adipic acid (final melting 152.9 ℃), and anthraquinone (final melting 285.7 ℃).

4. Precautions for Use of Melting Point Meter

1) The melting point meter shall be placed in a dry, dust-free, and ventilated laboratory environment to avoid excessive humidity and dust pollution and reduce the service life of the melting point meter. The principle of the instrument is acid, alkali, and other corrosive liquids;

2) During capillary sampling, pay attention to avoid capillary fracture and hand injury. If the sample to be tested generates toxic gas after decomposition, the instrument shall be put in the ventilation kitchen for testing. During the test, avoid contacting the heating part to prevent scalding;

3) After the instrument is used, the temperature drops to room temperature. Before the instrument is used, check whether the tube sleeve is assembled with the furnace body; Check whether the light source output is good.

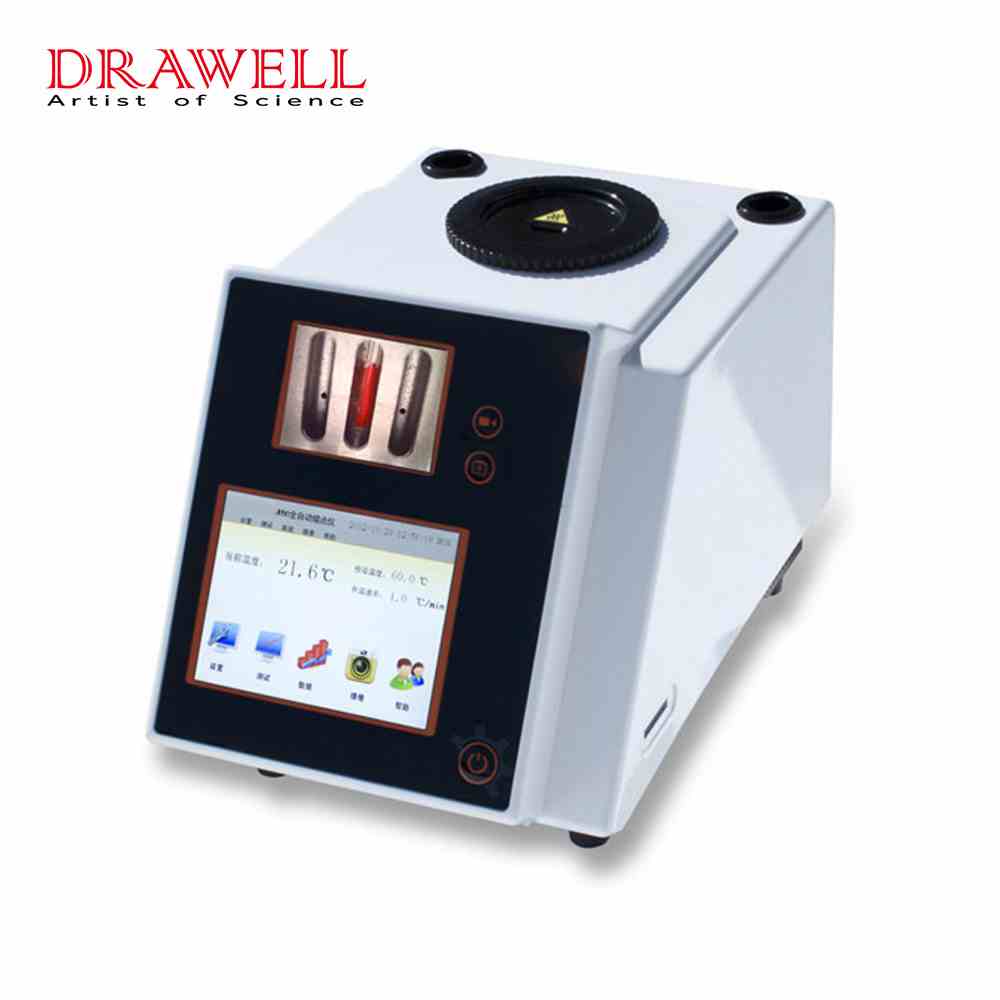

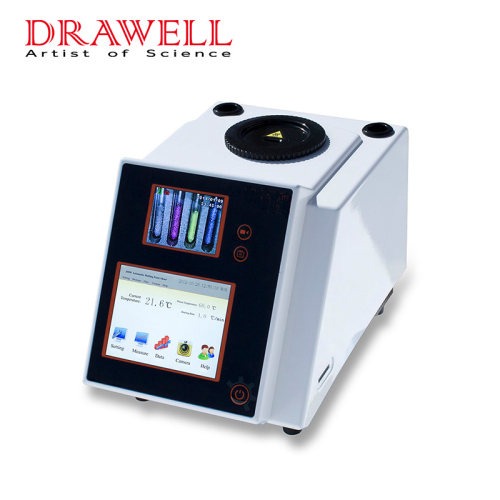

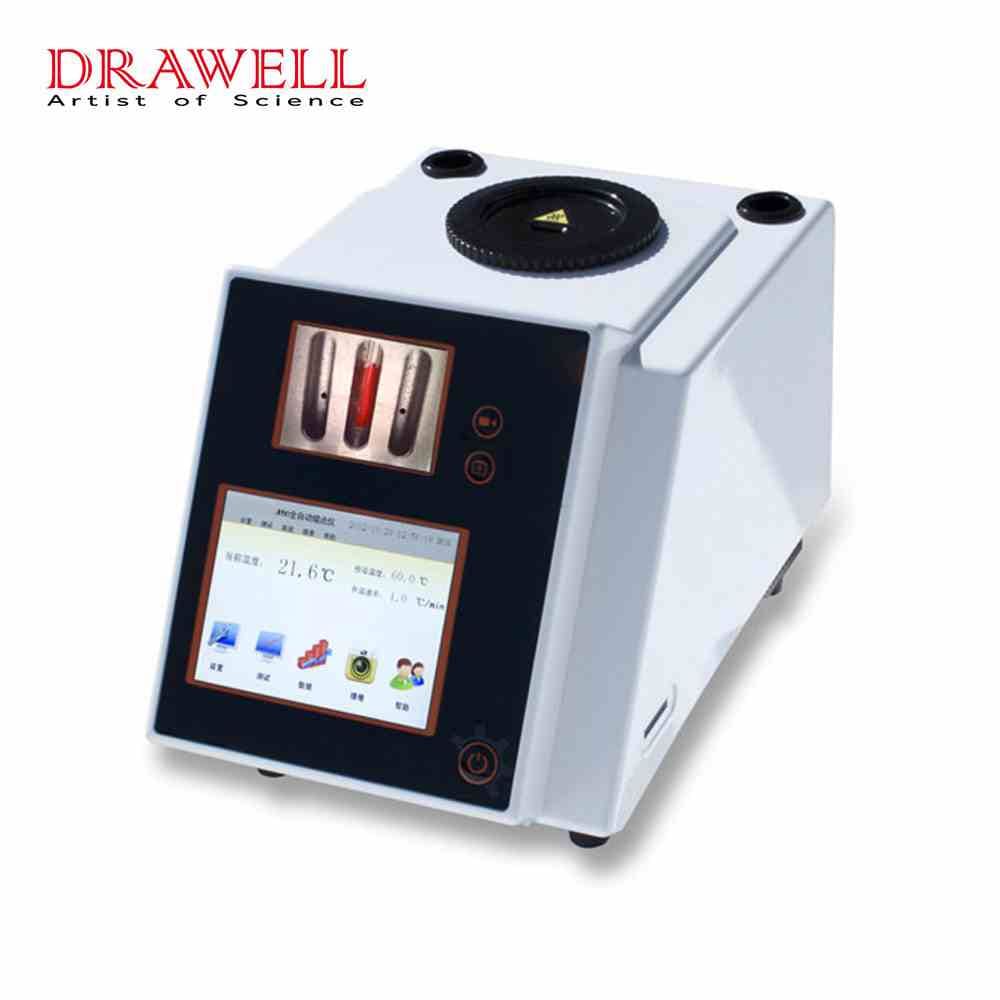

5. Precautions for Using the Automatic Melting Point Meter

1) The test sample is dried in advance and ground into powder by mortar. The capillary tube must be filled firmly with a filling height of 3 mm. It is necessary to remove the contaminants on the outer surface of the capillary tube when the capillary tube is connected to the instrument, to prevent contamination of the instrument, which may lead to failure of detection. If the capillary tube is broken or broken during the test, it should be powered off and taken out immediately.

2) In the sample test, the height of the same batch number should be consistent to ensure the consistency of the test results; Fill 5 pieces in the same batch, remove the maximum and minimum values after determination, and average the intermediate values to reduce experimental error;

3) The test temperature shall not exceed the operating temperature range of the instrument (<300 ℃). The measurement results are inconsistent with different linear heating rates. It is required to formulate certain specifications. The linear heating rate should be 1 ℃/min, the initial temperature should be 3 ℃~5 ℃ lower than the melting point, the linear heating rate should be 3 ℃/min, and the initial temperature should be 9 ℃~15 ℃ lower than the melting point.

Generally, the best test conditions should be determined by experiments. After measuring the sample with a higher melting point, measure the sample with a lower melting point, and directly input the instrument with a lower initial melting point temperature to automatically cool down. If there is a reference sample, the reference sample can be measured first, and a certain initial temperature and heating rate can be selected for comparative measurement according to the requirements. The initial melting point reading of the reference sample is used as the assessment basis. Units with melting point standards as temperature transfer standards can correct the results according to the readings of adjacent standards.