In modern industrial environments, ensuring consistent product quality is vital. The real-time Near-Infrared (NIR) spectrometer for inline quality control has emerged as a crucial technology to achieve this goal. Through providing real-time, non-invasive measurements during production processes, NIR spectrometers allow manufacturers to monitor and adjust product quality continuously, improving efficiency and reducing waste.

What is NIR Spectroscopy

This chart provides a concise overview of NIR spectroscopy, including its key principles, applications, and advantages.

| Aspect | Details |

| Full Name | Near-infrared Spectroscopy |

| Wavelength Range | 780 nm to 2500 nm (near-infrared region of the electromagnetic spectrum) |

| Principle | Based on absorption of near-infrared light by molecular bonds in materials |

| Common Molecular Bonds | O-H, C-H, N-H, and C-O bonds, which absorb NIR light at specific wavelengths |

| Application Areas | Pharmaceuticals, Food and Beverage, Agriculture, Polymers, Chemicals |

| Non-Destructive Analysis | Yes, allows analysis without damaging or altering the sample |

| Speed | Fast, real-time measurements are possible |

| Data Output | Spectra showing absorbance or reflectance at different wavelengths |

| Advantages | Non-invasive, rapid, no sample preparation, real-time monitoring |

| Typical Uses | Moisture content, protein, fat, chemical composition, and material identification |

| Limitations | Less sensitive than mid-infrared, requires calibration, cannot measure all compounds |

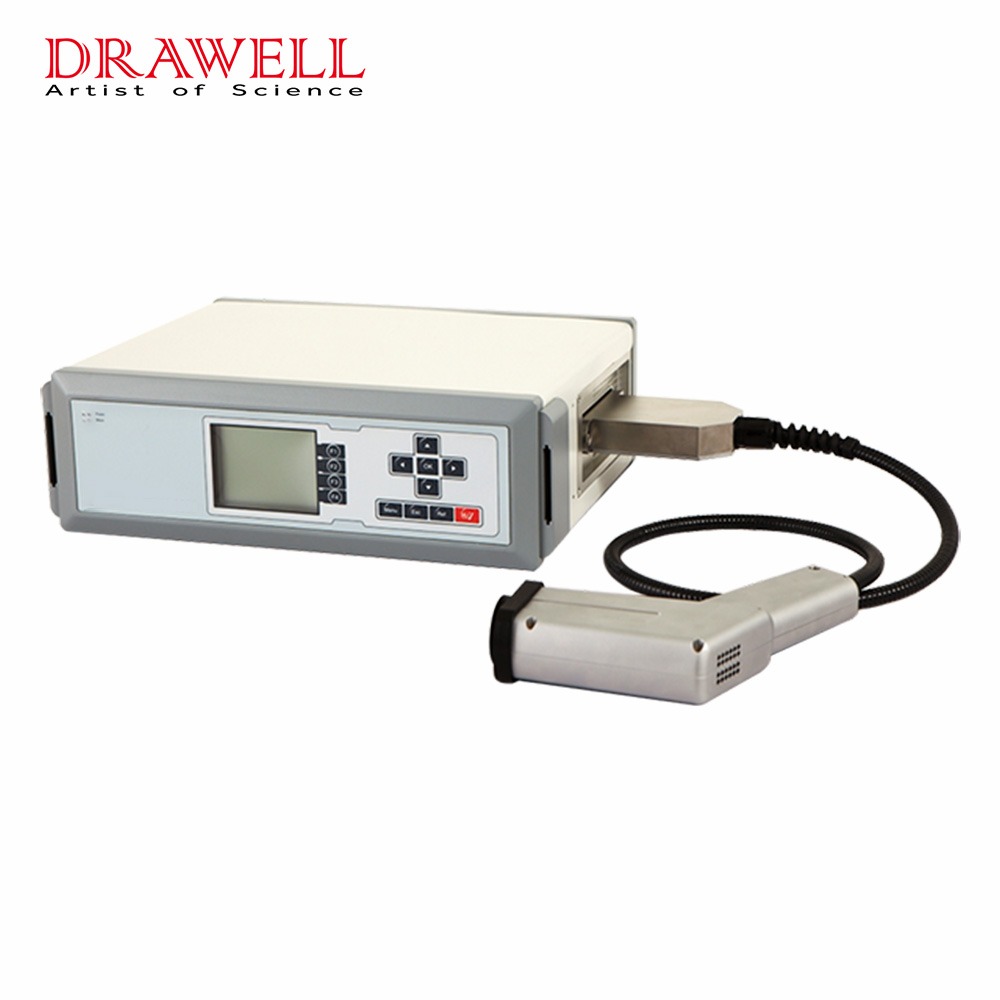

| Key Instruments | Benchtop spectrometers, handheld devices, inline/real-time spectrometers |

| Data Analysis Techniques | Multivariate analysis, calibration models, chemometrics |

Benefits of Real-Time NIR Spectrometers for Inline Quality Control

- Non-Destructive Analysis: Real-time Near-infrared spectrometers provide non-invasive measurements, allowing manufacturers to assess product quality without altering or damaging the material.

- Instant Feedback: NIR spectrometers enable real-time monitoring of key parameters, ensuring immediate detection of any deviations in quality. This allows for rapid corrective actions, improving consistency.

- Increased Efficiency: By eliminating the need for off-line sampling and lab-based testing, inline NIR spectrometers reduce downtime, allowing continuous production and increased throughput.

- Cost Savings: Real-time quality control minimizes material waste, energy consumption, and rework by identifying quality issues early in the process, leading to overall cost reductions.

- Improved Product Quality: Inline NIR spectrometers offer precise control over quality parameters such as moisture, fat, protein, and other critical components, ensuring consistent product quality throughout the production cycle.

- Reduced Human Error: Automation of the quality control process reduces reliance on manual sampling and testing, minimizing the potential for human errors in production.

- Regulatory Compliance: Many industries, such as pharmaceuticals and food production, benefit from the real-time monitoring capabilities of NIR spectrometers to ensure products meet stringent regulatory standards.

- Enhanced Data Collection: Continuous, real-time data collection allows for detailed analysis of trends in production, enabling process optimization and better decision-making.

- Versatile Application: NIR spectrometers can be applied across multiple industries, including pharmaceuticals, food and beverage, chemicals, and agriculture, to monitor a wide range of quality parameters.

- Sustainability: By reducing waste and rework, inline NIR systems contribute to more sustainable manufacturing practices, conserving resources and minimizing environmental impact.

Key Applications of NIR Spectrometers in Inline Quality Control

1. Food and Beverage Industry

In food production, NIR spectrometry is used to monitor moisture, fat, protein, and sugar levels in real-time. For example, bakeries use inline NIR systems to control dough moisture content, ensuring optimal texture and shelf life. Dairy producers can monitor fat and protein content in milk to maintain consistent quality in cheese and yogurt production.

2. Pharmaceutical Industry

Near-infrared spectrometers help ensure that pharmaceutical products meet strict regulatory standards. Inline systems measure the active pharmaceutical ingredient (API) content, moisture levels, and blend uniformity during tablet production, reducing the risk of dosage errors and improving the efficiency of the manufacturing process.

3. Chemical Industry

In chemical manufacturing, near-infrared technology is used for monitoring and controlling the composition of chemical mixtures. This ensures that products such as plastics, adhesives, and coatings meet precise specifications, enhancing product performance and reducing the risk of defects.

4. Agriculture and Feed Industry

Farmers and feed producers use NIR spectrometers to analyze the nutritional content of crops and animal feed. By monitoring moisture, protein, and fiber content in real-time, they can optimize feed formulations and ensure consistent quality in their products.

Integrating Real-time NIR Spectrometers into Production Lines

The integration of real-time NIR spectrometers into existing production lines requires careful planning and customization.

| Key Steps | Description |

| 1.Understanding Production Needs | Analyze quality parameters to determine how NIR spectrometer integration aligns with production goals. |

| 2. Selecting the Right Spectrometer | Choose a compact, robust near-infrared model tailored for specific industry applications and measurement needs. |

| 3. Mounting and Placement | Position the spectrometer at critical points (e.g., conveyors, mixers) to ensure accurate readings. |

| 4. Integration with Control Systems | Connect the NIR spectrometer to the central control system for automated process adjustments. |

| 5. Data Communication | Ensure digital connectivity via Ethernet, OPC, or fieldbus for efficient data sharing. |

| 6. Calibration and Testing | Develop and regularly update calibration models to maintain accuracy. |

| 7. Real-time Monitoring | Set up real-time monitoring and alerts for immediate quality control interventions. |

| 8. Training and Support | Train staff on operating the near-infrared system, interpreting data, and responding to alerts. |

| 9. Maintenance and Upkeep | Perform regular cleaning and maintenance to maintain spectrometer accuracy and functionality. |

| 10. Compliance with Standards | Ensure compliance with industry standards and regulatory requirements for quality assurance. |

In summary, real-time NIR spectrometers are revolutionizing inline quality control across a wide range of industries. By providing immediate, non-destructive analysis of product composition, near infrared spectrometers enhance efficiency, reducing costs, and ensuring that products meet the highest quality standards.