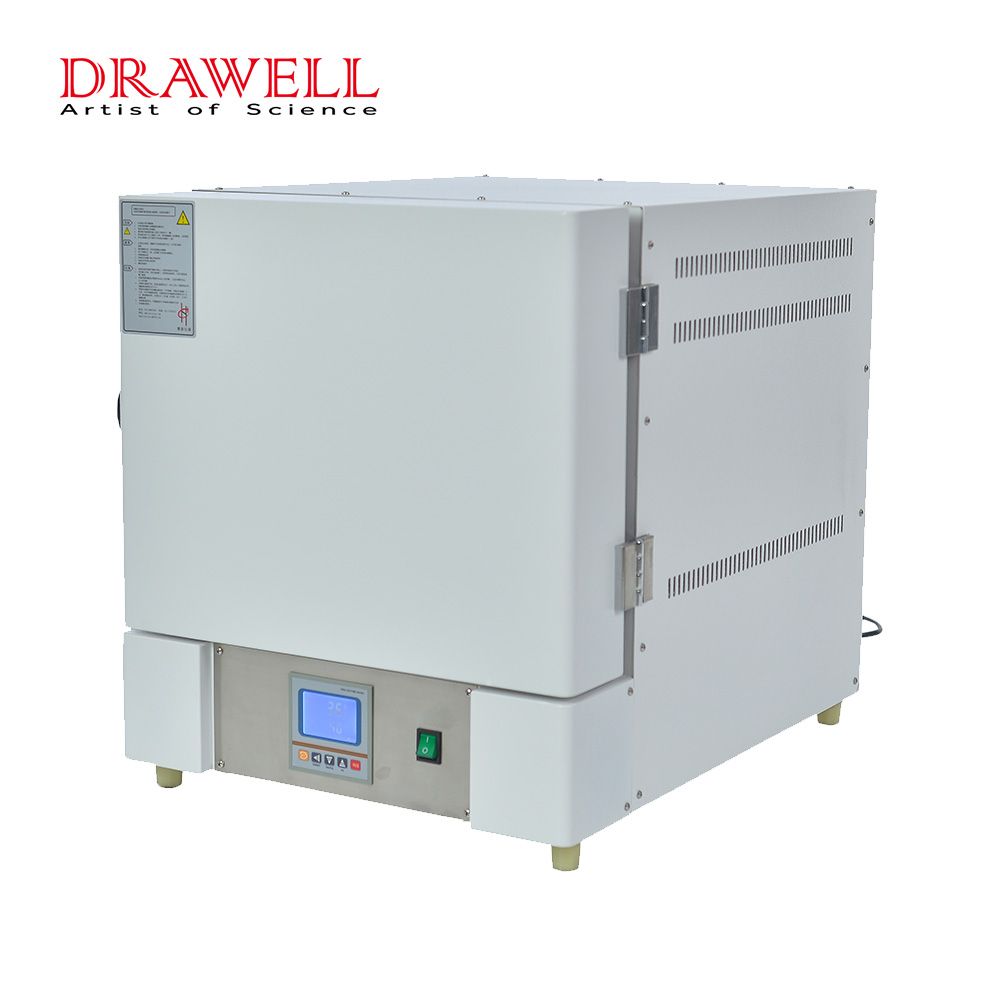

Muffle furnaces are indispensable tools in the world of materials testing and research, providing a controlled environment for high-temperature applications. These robust devices are essential for processes such as annealing, sintering, and heat treatment, which are critical for studying various materials’ properties. In this article, we will explore the muffle furnace temperature range, factors affecting muffle furnace temperature, and the wide-ranging applications of muffle furnaces in materials testing and research.

Definition of Muffle Furnace Temperature Range

Muffle furnaces are designed to reach and maintain specific temperature ranges, making them versatile instruments for a variety of heat-related processes. The temperature range of muffle furnaces and high-temperature muffle furnaces can vary depending on the specific model and manufacturer. However, as a general guideline:

- Muffle Furnace: Standard muffle furnaces typically have a temperature range of around 300°C (572°F) to 1,200°C (2,192°F). These are suitable for a wide range of applications, including ashing, annealing, and general heat treatment processes.

- High-Temperature Muffle Furnace: High-temperature muffle furnaces, as the name suggests, are designed for applications that require extremely high temperatures. They can often reach temperatures in the range of 1,200°C (2,192°F) to 1,800°C (3,272°F) or even higher, depending on the specific model. These are used for more specialized applications, including materials testing, ceramics production, and certain advanced heat treatment processes.

It’s important to note that there are variations among different furnace models and manufacturers, so you should always consult the product specifications provided by the manufacturer to determine the precise temperature range of a specific muffle furnace or high-temperature muffle furnace.

Factors Affecting Muffle Furnace Temperature

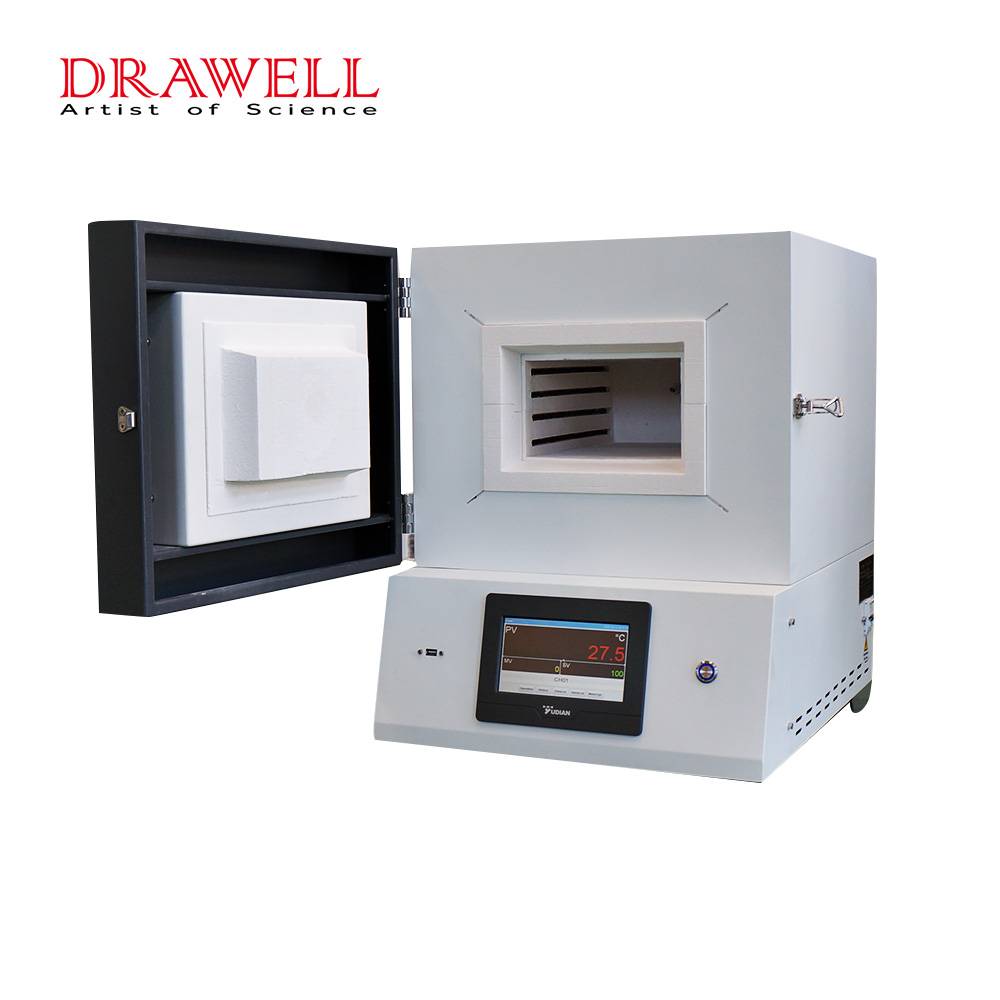

- Heating Elements: The primary factor influencing muffle furnace temperature is the type and quality of the heating elements used. Most muffle furnaces employ either resistance wire or silicon carbide heating elements. The choice of heating element impacts the furnace’s maximum temperature, heating speed, and overall durability.

- Insulation: The furnace’s insulation material plays a vital role in maintaining temperature stability. High-quality insulation materials help reduce heat loss, improve energy efficiency, and ensure a more uniform temperature distribution within the chamber.

- Temperature Control: Accurate temperature control is achieved through the use of advanced controllers and sensors. Modern muffle furnaces are equipped with digital controllers that can maintain temperature within tight tolerances, ensuring precise and consistent heat treatment.

- Airflow and Ventilation: Adequate ventilation is essential to prevent overheating and maintain temperature uniformity. Many muffle furnaces have built-in fans and vents to control airflow and prevent temperature fluctuations.

- Sample Size and Load: The size and composition of the sample inside the muffle furnace can affect the temperature. Larger or denser samples may require more time to reach the desired temperature, and their presence can impact heat distribution within the furnace chamber.

Applications in Materials Testing and Research Owing to Versatility in Muffle Furnace Temperature Range

Muffle furnaces find a wide array of applications in materials testing and research, owing to their versatility in handling different temperature-controlled processes. Some of the key applications include:

- Annealing: Annealing is a heat treatment process that alters the properties of materials, making them more ductile or reducing hardness. Muffle furnaces are used to heat materials to specific temperatures and then cool them slowly to achieve desired material properties.

- Sintering: In the field of ceramics and powder metallurgy, muffle furnaces are crucial for sintering processes. They help bind fine particles together through controlled high-temperature heating, creating solid materials with improved mechanical strength.

- Drying: Muffle furnaces are commonly used for drying and removing moisture from samples, a critical step in sample preparation for materials testing.

- Catalyst Activation: Researchers often use muffle furnaces to activate catalysts by heating them to precise temperatures. This is vital in catalytic chemistry and catalysis research.

- Pyrolysis: Muffle furnaces are employed for pyrolysis, a process that involves the decomposition of organic materials at high temperatures, resulting in the formation of new materials or charred residues.

- Quality Control: Muffle furnaces are used in quality control laboratories to verify the properties of materials, ensuring they meet the required standards for strength, hardness, and other characteristics.

- Environmental Testing: Muffle furnaces are also used in environmental testing, such as simulating high-temperature conditions to study materials’ behavior in extreme environments.

Conclusion

Muffle furnaces are invaluable tools in materials testing and research, enabling scientists and engineers to perform a wide range of high-temperature processes with precision and control. Understanding the muffle furnace temperature range and the factors that affect it is essential for ensuring reliable and repeatable results in various applications. Whether it’s annealing, sintering, catalyst activation, or quality control, muffle furnaces play a crucial role in advancing our knowledge of materials and their properties.