As you know there are many types of drying ovens, today this article will introduce the types of drying ovens and the precautions for vacuum ovens.

Types of Drying Ovens

Drying ovens can generally be divided into electric drying ovens and infrared drying ovens. The electric drying oven is usually called a vacuum oven or a drying oven. It is a device that uses an electric heating wire to heat through air convection to dry objects. The electric drying oven commonly used in the laboratory is suitable for constant temperature baking within the range of room temperature to 300°C, drying samples, reagents, utensils, and other materials, and determining moisture. The infrared drying oven uses the infrared rays generated by the heating element to penetrate the object to be heated, so the heating speed is fast, the energy consumption is small, and the heating quality is high.

1. Vacuum oven

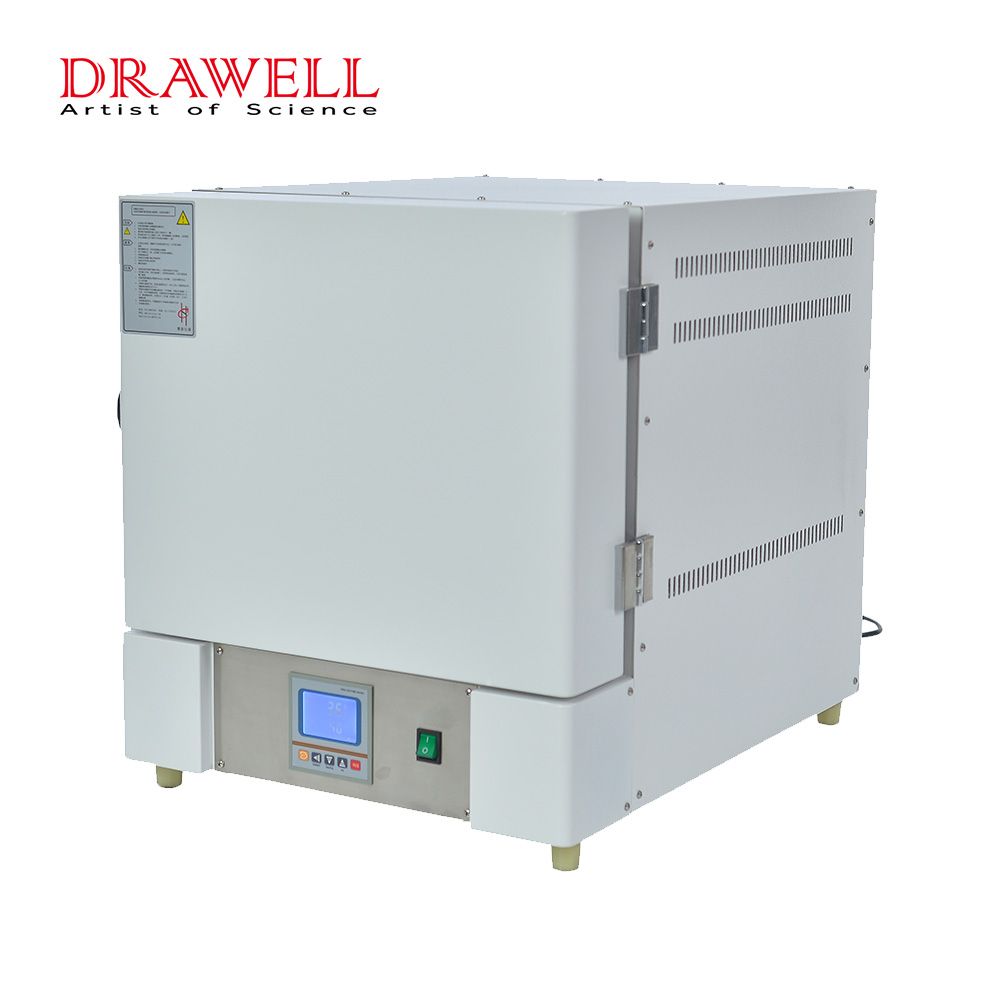

There are many types of vacuum ovens. Common drying ovens include electric heating constant temperature drying ovens, electric heating blast drying ovens, electric heating constant temperature blast drying ovens, electric heating vacuum drying ovens, etc. Their structures are similar, mainly composed of three parts: a box body, an electric heating system, and an automatic constant temperature control system.

The box body of the vacuum oven includes the shell, the insulation layer, the working room, the glass door, and other parts. The porcelain tank is fixed in the interlayer of the box body. The automatic constant temperature system includes a temperature controller and a temperature indicator.

As you know, many varieties, models, and specifications of vacuum ovens exist in the world. According to the highest constant temperature and humidity, there are two types: 10-200°C and 10-300°C, and according to the electric power, it is divided into 1kw, 2kw, 4kw, 5kw, etc.

2. Infrared drying oven

An infrared ray is a kind of electromagnetic wave with a wavelength of 0.75-1000μm. When the infrared ray is projected onto an object, the object absorbs a large amount of infrared energy, thereby changing and furnishing its molecular motion to achieve heating.

The characteristics of infrared heating are: infrared rays can be injected into the surface of the object to be heated to a certain depth, so the heating speed is accelerated, the power consumption is less, and the heating quality is high.

The infrared heating drying oven commonly used in analytical laboratories mainly uses lamp-type electric heating elements, that is, infrared lamps, as heat sources. One of them is a group of infrared lamps (250W each) connected in parallel for heating without an automatic temperature control system. A maximum of 12 infrared bulbs can be used in parallel in one group, and the other is an infrared drying oven with automatic constant temperature control, depending on the used The power size and the maximum operating temperature can be divided into two specifications: 10-300°C and 10-450°C.

Precautions for the Use of Vacuum Oven

- Flammable, explosive, and corrosive substances such as volatile chemicals, low-concentration explosive gases, and low-fire point gases cannot be commonly used in vacuum ovens.

- When using rapid auxiliary heating, the staff should continuously observe the temperature rise on the spot, and when the required temperature is reached, turn the switch to the constant temperature position.

- Reagents and glass instruments should be dried separately to avoid mutual contamination. There should be space between the items in the vacuum drying box, and it should not be too dense.

- When using a drying oven without the blast, the thermometer should be inserted close to the object to be baked, to accurately indicate and control the temperature. In addition, it is not allowed to place the object to be baked on the bottom plate of the oven, because the bottom plate is directly heated by the electric heating wire, and the temperature greatly exceeds the temperature controlled by the drying oven.

5. For the electric drying oven with a blower device, the blower must be turned on during the heating and constant temperature process, otherwise it will affect the uniformity of the temperature in the working room and damage the heating element.

6. When the vacuum oven is in use, the exhaust valve on the top should be unscrewed to allow water vapor to escape. When the vacuum oven is stopped, the exhaust valve should be closed in time to prevent moisture and dust from entering.

7. When you need to observe the condition of the items in the box, you can open the outer door to observe through the glass, but you should open the door as little as possible to avoid affecting the constant temperature. Especially when the working temperature does not exceed 200°C, opening the door may cause the glass door to freeze and break.

If you want to know more about precautions for vacuum drying oven, please click here.