High Pressure Homogenizers (HPHs) have become an indispensable tool in the pharmaceutical industry, revolutionizing the way drugs are formulated and produced. By applying extremely high pressures to substances, HPHs break down particles and create uniform, stable mixtures. This process is crucial for ensuring the effectiveness, stability, and bioavailability of pharmaceutical products. This article explores the reasons for using HPHs in pharmaceuticals, their applications in manufacturing, and their impact on the industry.

Why using High Pressure Homogenizers in Pharmaceuticals?

High Pressure Homogenizers (HPHs) are critical tools in the pharmaceutical industry due to their ability to improve drug formulations significantly. Here are the key reasons for their widespread use:

Enhanced Bioavailability

One of the primary advantages of HPHs is their ability to enhance the bioavailability of drugs. Bioavailability refers to the proportion of a drug that reaches the bloodstream and, consequently, the site of action. Many new drug candidates have poor water solubility, which limits their absorption in the body. HPHs address this issue by reducing the particle size of these drugs to the nanometer scale. The increased surface area of the smaller particles leads to a higher dissolution rate, which in turn improves the drug’s bioavailability. This enhancement is crucial for ensuring that the drug is effective at lower doses, reducing potential side effects and improving patient compliance.

Improved Stability and Shelf Life

HPHs play a vital role in enhancing the stability and shelf life of pharmaceutical formulations. The homogenization process creates uniform and stable emulsions and suspensions, preventing the separation of ingredients over time. This stability is essential for maintaining the efficacy and safety of the drug during storage and transportation. By producing smaller and more uniform particles, HPHs minimize the risk of degradation and improve the chemical and physical stability of the formulation. This results in a longer shelf life and consistent performance of the pharmaceutical product.

Consistent Product Quality

Consistency in product quality is a critical factor in pharmaceutical manufacturing. Variations in particle size and distribution can lead to differences in drug performance, safety, and efficacy. HPHs ensure that each batch of product meets the same high standards by producing uniform particle sizes and distributions. This uniformity is crucial for achieving consistent therapeutic outcomes and for meeting regulatory requirements. The ability to maintain consistent quality across batches enhances the reliability of the pharmaceutical product and builds trust with healthcare providers and patients.

Scalability and Efficiency

High pressure homogenization is a scalable process, making it suitable for both small-scale laboratory research and large-scale industrial production. The technology allows for efficient processing of large volumes of material, which is essential for cost-effective mass production. The continuous nature of the homogenization process reduces batch-to-batch variability and increases overall production efficiency. Additionally, HPHs can be integrated into existing manufacturing processes, providing flexibility and scalability as production demands change.

Enhanced Drug Delivery Systems

HPHs contribute to the development of advanced drug delivery systems, such as liposomes and nanoparticles, which offer targeted and controlled release of drugs. These delivery systems improve therapeutic outcomes by delivering the drug directly to the site of action, minimizing systemic side effects and enhancing patient compliance. HPHs enable the production of these sophisticated drug delivery vehicles with high precision and uniformity, supporting the advancement of personalized medicine and innovative treatments.

High Pressure Homogenizers have become indispensable in the pharmaceutical industry due to their ability to enhance bioavailability, improve stability, ensure consistent product quality, and offer scalability and efficiency. Their versatility in various applications, from particle size reduction to advanced drug delivery systems, makes them a valuable asset in the development and production of effective pharmaceutical formulations. Let’s know more about its applications.

Applications of HPHs in Pharmaceutical Manufacturing

From improving the bioavailability of poorly soluble drugs to producing sophisticated nanoparticle and liposomal formulations, High Pressure Homogenizers (HPHs) play a pivotal role in modern pharmaceutical processes. The table below provides an overview of these applications, including descriptions and practical examples, highlighting the versatility and indispensability of HPH technology in the pharmaceutical industry.

| Application | Description | Examples |

| Particle Size Reduction | Reduces the size of drug particles to the nanometer scale, enhancing dissolution rates and bioavailability. | Cancer therapies, cardiovascular drugs |

| Emulsification | Creates fine, stable emulsions by forcing immiscible liquids through a narrow gap under high pressure. | Creams, lotions, injectable drugs |

| Suspension Homogenization | Ensures uniform distribution and stability of solid particles in a liquid medium. | Antibiotic suspensions, corticosteroid suspensions |

| Liposomal Encapsulation | Produces liposomes, enhancing drug delivery and reducing toxicity by encapsulating drugs within lipid bilayer vesicles. | Cancer therapies, vaccine formulations |

| Nanoparticle Formation | Generates nanoparticles for controlled release and targeted drug delivery. | Precision medicine, advanced drug delivery systems |

| Cell Disruption | Disrupts cells to extract intracellular contents like proteins and enzymes, important for biopharmaceutical production. | Biopharmaceuticals, enzyme extraction |

Choosing a High Pressure Homogenizer Manufacturer

High Pressure Homogenizers (HPHs) have become an essential technology in pharmaceutical manufacturing, offering a myriad of applications that significantly enhance drug formulations. By improving bioavailability, stability, and consistency, HPHs contribute to the development of more effective and reliable pharmaceutical products. Their versatility in applications such as particle size reduction, emulsification, suspension homogenization, liposomal encapsulation, and nanoparticle formation underscores their pivotal role in the industry.

As pharmaceutical companies continue to innovate, the demand for advanced homogenization technologies will grow. High pressure homogenizer manufacturers are responding to this demand by developing more sophisticated and efficient machines that can meet the stringent requirements of modern drug production. However, potential buyers must carefully consider the high pressure homogenizer price, as it can vary widely based on the machine’s capabilities, capacity, and the manufacturer’s reputation. Investing in high-quality HPHs can lead to long-term benefits, including improved drug efficacy, lower production costs, and enhanced patient outcomes.

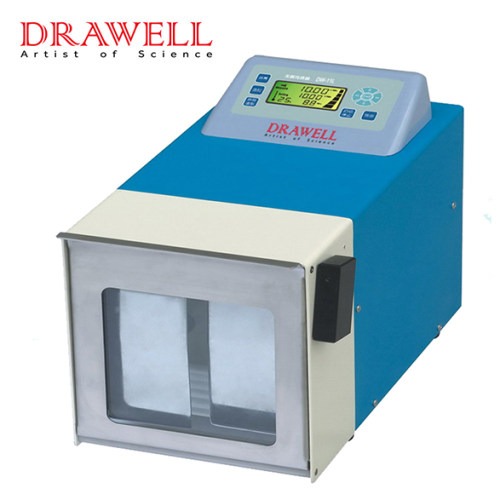

Drawell is a professional lab equipment manufacturer and supplier, can providing you high quality high pressure homogenizer with reliable services. Feel free to contact them when you need.