High-speed centrifuges are essential instruments in scientific and industrial laboratories, used for separating components of a mixture based on their density. The sample capacity and flexibility offered by high-speed centrifuges are critical factors that enhance their utility across a wide range of applications. This article explores these capabilities, highlighting their importance and impact on diverse fields.

Understanding High-speed Centrifuges

High-speed centrifuges are designed to spin samples at very high speeds, typically ranging from 10,000 to 30,000 revolutions per minute (RPM). The centrifugal force generated during this process separates particles based on their size, shape, and density. This separation is crucial for numerous scientific and industrial processes, including biological research, chemical analysis, and pharmaceutical development.

Sample Capacity of High-speed Centrifuges

The sample capacity of these centrifuges is influenced by several key factors, including rotor design, tube and bottle size, and balance requirements.

1. Rotor Design

Fixed-Angle Rotors

- Description: Hold samples at a constant angle relative to the axis of rotation.

- Capacity: Typically support smaller volumes but offer higher speeds.

- Applications: Ideal for quick separations and smaller samples, such as pelleting cells or subcellular fractions.

Swinging-Bucket Rotors

- Description: Allow sample containers to swing out to a horizontal position during centrifugation.

- Capacity: Accommodate larger sample volumes and provide versatility in handling different sample types.

- Applications: Suitable for gradient centrifugation and separating larger volumes of liquids.

Vertical Rotors

- Description: Hold tubes vertically, reducing the path length for particle sedimentation.

- Capacity: Generally used for density gradient separations, handling moderate to large sample volumes.

- Applications: Useful in purifying viruses, organelles, and macromolecules.

2. Tube and Bottle Size

Microcentrifuge Tubes

- Volume Range: Typically 0.5 mL to 2 mL.

- Usage: Commonly used for micro high-speed centrifuge in molecular biology for small-scale applications such as DNA/RNA extraction.

Standard Tubes

- Volume Range: 5 mL to 50 mL.

- Usage: Suitable for a wide range of biological and chemical applications, including cell culture and protein purification.

Large Bottles

- Volume Range: 250 mL to several liters.

- Usage: Used in industrial and large-scale laboratory settings for bulk separations and large-volume sample processing.

3. Balance and Symmetry

To ensure the efficient and safe operation of a high-speed centrifuge, samples must be balanced symmetrically. This balance requirement can affect the number of samples that can be processed simultaneously:

Symmetrical Loading

- Description: Samples must be evenly distributed around the rotor to maintain balance.

- Impact on Capacity: This requirement can limit the number of samples processed if uneven or odd numbers of samples are being handled. Using adapters and spacers can help achieve balance.

4. Accessories and Adaptations

Adapters

- Function: Allow the use of smaller tubes in rotors designed for larger tubes, increasing flexibility and capacity options.

- Benefits: Enhance the versatility of the centrifuge by accommodating various tube sizes within the same rotor.

Spacers

- Function: Help balance the rotor when processing fewer samples or samples of different volumes.

- Benefits: Ensure balanced loading, reducing wear and tear on the centrifuge and improving safety.

Flexibility in High-speed Centrifuges

High-speed centrifuges are versatile instruments designed to accommodate a wide range of applications across various industries. Their flexibility is a key attribute that allows them to handle diverse sample types, meet specific processing requirements, and enhance efficiency in scientific and industrial settings.

1. Interchangeable Rotors

One of the primary features contributing to the flexibility of high-speed centrifuges is the availability of interchangeable rotors. These rotors vary in size, configuration, and capacity, allowing users to select the most suitable option based on their specific needs:

- Fixed-Angle Rotors: Hold tubes at a fixed angle relative to the axis of rotation. They are ideal for high-speed applications and are commonly used in molecular biology and biochemistry for pelleting and isolating cellular components.

- Swinging-Bucket Rotors: Allow tubes or bottles to swing outward during centrifugation, providing more uniform separation of samples, especially useful for gradient separations and large-volume processing.

- Vertical Rotors: Hold tubes vertically, reducing the path length for sedimentation. They are preferred for density gradient separations and processing of larger volumes.

The ability to interchange these rotors enables the centrifuge to handle different sample volumes, densities, and specific separation requirements effectively.

2. Variable Speed and Temperature Control

High-speed centrifuges offer adjustable speed settings, typically ranging from 10,000 to 30,000 RPM or higher. Variable speed control allows users to optimize centrifugation conditions based on the sample type and desired separation protocol:

- Speed Control: Enables precise adjustment of centrifugal force, essential for separating particles of varying sizes and densities.

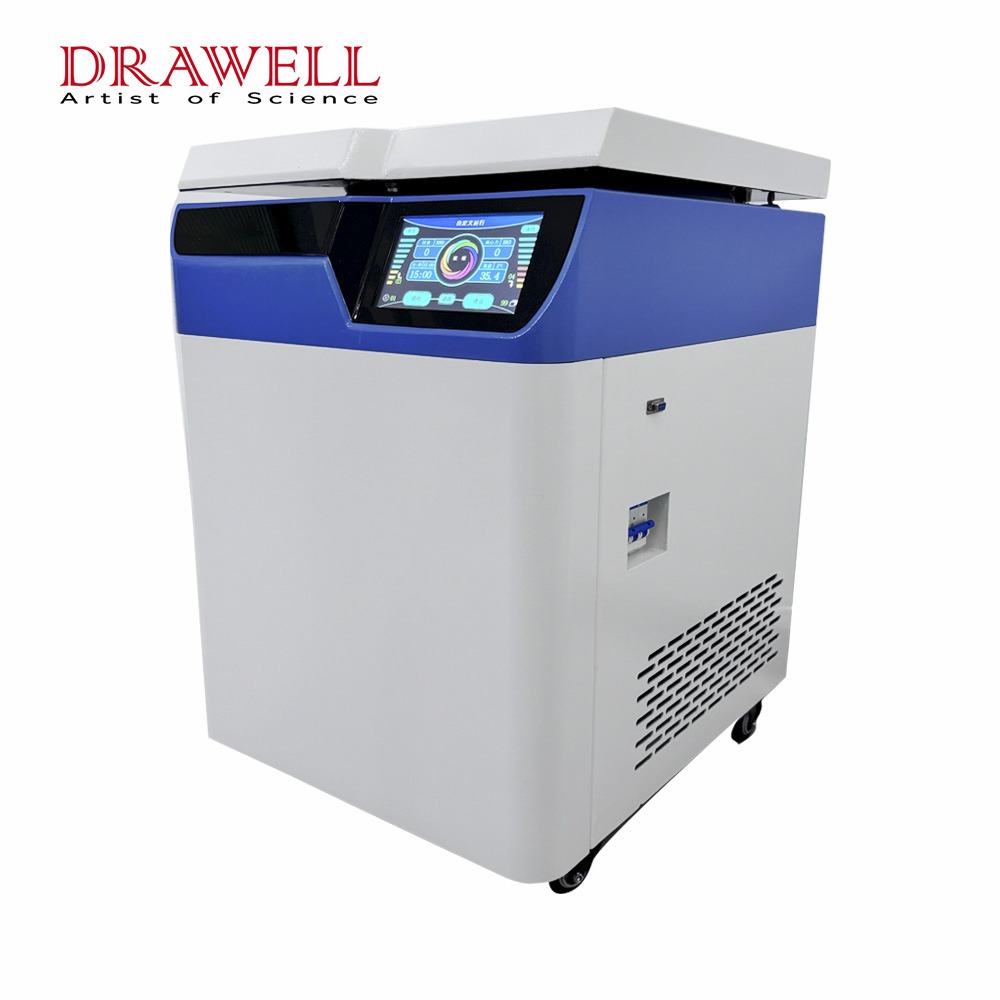

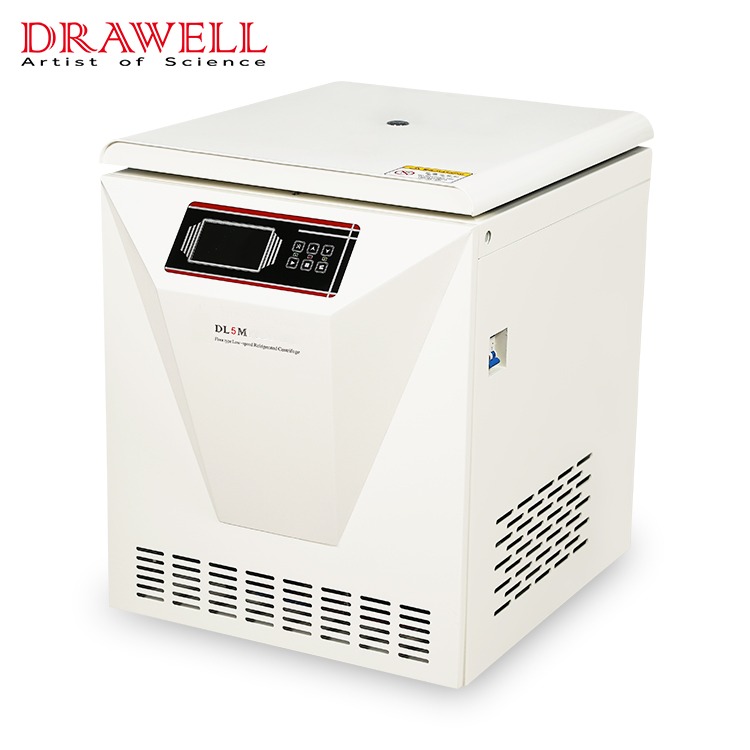

- Temperature Control: Many advanced models feature temperature control capabilities, allowing samples to be cooled or heated during centrifugation. High-speed refrigerated centrifuge is critical for preserving sample integrity, especially for temperature-sensitive materials such as proteins, enzymes, and biological samples.

3. Programmable Settings

Modern high-speed centrifuges often come equipped with programmable settings that allow users to customize centrifugation protocols:

- Acceleration and Deceleration Rates: Adjustable rates ensure gentle handling of delicate samples and reduce the risk of sample disturbance or damage.

- Spin Time: Users can set specific spin durations to achieve optimal separation without unnecessary centrifugation.

- Speed Profiles: Programmable speed profiles accommodate complex separation protocols, such as multi-step gradients or sequential sample processing.

These programmable features enhance reproducibility, efficiency, and flexibility in centrifuge operations, particularly in high-throughput environments where consistent results are crucial.

4. Compatibility with Various Sample Types

High-speed centrifuges are designed to accommodate a wide range of sample types, including:

- Biological Samples: Such as cells, tissues, and subcellular components for applications in molecular biology, microbiology, and clinical diagnostics.

- Chemical Samples: Including solvents, reagents, and chemical mixtures for analytical and industrial processes.

- Environmental Samples: Such as water, soil, and air particulates for environmental monitoring and analysis.

The ability to handle diverse sample types makes high-speed centrifuges indispensable tools in research, pharmaceutical development, quality control, and environmental sciences.

Applications Enhanced by Sample Capacity and Flexibility of High-speed Centrifuges

This chart illustrates how the sample capacity and flexibility of high-speed centrifuges enhance their applications across various industries, highlighting the specific requirements and benefits for each application.

| Industry | Application | Specific Requirements | Benefits |

| Biological Research | Isolation of nucleic acids, proteins, and organelles | Variable speed and temperature control, ability to handle different sample volumes | Enhanced precision, reproducibility, and efficiency |

| Clinical Diagnostics | Separation of blood components (plasma, serum) | Flexibility to process various sample volumes, programmable settings | Efficient workflow, accurate diagnostic results |

| Pharmaceutical Development | Purification of compounds, separation of active ingredients | Precision in speed and temperature control, compatibility with various sample types | Improved purity and yield, critical for drug development |

| Environmental Analysis | Analysis of water and soil samples | Ability to process large sample volumes, interchangeable rotors | Increased accuracy and efficiency in contaminant detection |

| Industrial Applications | Processing of chemical mixtures, sedimentation | High sample capacity, robust design to handle industrial-scale volumes | Enhanced processing speed, reliability, and scalability |

| Food and Beverage Industry | Separation of ingredients, quality control | Adjustable speed settings, ability to handle diverse sample types | Improved product quality and consistency |

Conclusion

The capabilities of high-speed centrifuges in terms of sample capacity and flexibility make them invaluable tools in numerous scientific and industrial applications. Their ability to handle diverse sample types, volumes, and separation requirements ensures they meet the specific needs of various fields.