What is a High Pressure Homogenizer (HPH)?

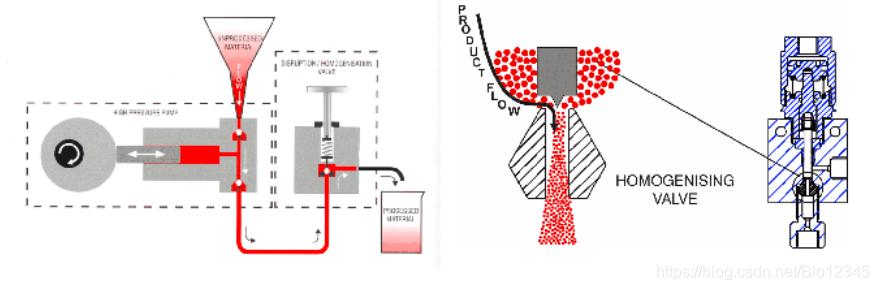

High-pressure homogenizer HPH is online dispersion equipment with high efficiency, energy saving, and continuous production of ultrafine emulsion. In contrast to other in-line equipment from IKA, the dispersing action of the HPH is not based on the rotor/stator principle. Better homogenization is achieved in the homogenizer by self-decompression of the liquid from up to 2000 bar to ambient pressure.

Drawell HPH has the same energy input and produces more acceptable emulsions than conventional gear ring dispersers. When disintegration down to the nanoscale is required, high-pressure homogenizers are recommended; however, these homogenizers achieve lower flow rates than conventional dispersions.

How to Use a High Pressure Homogenizer?

1. Installation

Place the high-pressure homogenizer on a flat and sturdy desktop, and install the high-pressure pump, homogenizer valve, pressure gauge, check valve, sample tank, and other components one by one after they are in place (each component is relatively independent and can be disassembled and installed independently).

At the same time, prepare an air compressor or nitrogen tank and circulate cooling water. The air compressor or nitrogen tank is used to provide the minimum pressure (5-10bar) required by the dynamic homogenization valve and the pressure when the pipeline is flushed, and the circulating cooling Water is used as a cold source when the sample is refrigerated, which can ensure that the sample maintains a low temperature during the homogenization process, avoiding sample denaturation and inactivation.

2. Cleaning and Disinfection

Before starting the machine, check the entire sample path to ensure the cleanliness of the tubing. Remove all components in the entire sample channel, rinse with pure water first, then rinse with 0.5M NaOH for a short time, and finally rinse with warm water.

After cleaning, each component can be sterilized with hot steam, and the pipeline can also be sterilized by a hot steam cycle for about 10 minutes after installation.

3. Operation

Before the homogenizer is started, check the homogenized liquid to ensure that it does not contain impurities. Impurity particles, especially metal particles, will damage the pipeline and the homogenizing valve and shorten the service life of the homogenizer.

Check the pipeline of the high-pressure homogenizer to ensure that all components are properly installed and sealed, and the bolts are fully locked; check the air source (compressor or nitrogen tank, etc.) to ensure that the pressure required for work can be provided; check the cooling water, to ensure that the cooling circulating water has been prepared in advance according to the process requirements, and the cooling water pipeline is connected.

Before the HPH of the high-pressure homogenizer starts working, the small amount of liquid remaining in the pipeline is completely emptied, and then the sample is introduced into the sample tank and pre-homogenized twice under air pressure.

Then increase the homogenization pressure according to the work requirements and start homogenization. After the homogenization is completed, the pressure is reduced to zero, and the material liquid is emptied.

4. Maintenance

Immediately after the homogenization is completed, rinse with warm water and 0.5M NaOH in a cycle, and finally rinse with clean water. During this process, it can be properly aerated and pressurized to speed up the cycle, so that the pipeline can be rinsed more quickly and thoroughly. Rinse 1-2 times with 50% alcohol to complete the entire cleaning process.

After cleaning the tubing, fill the sample tank and tubing with 70% alcohol solution for the next use. If it is necessary to sterilize the entire pipeline, after the cleaning is completed, the pipeline is sterilized by a hot steam cycle for about 10 minutes.

Finally, shut down, cut off the power supply, turn off the air source and cooling water, etc.

Precautions for Using High Pressure Homogenizer

1. Homogenizing pressure

The homogenization pressure of the high-pressure homogenizer is determined according to the characteristics of the material and liquid. During the process of increasing the pressure, the pressure should be gradually adjusted to avoid sudden changes in the pressure.

During the homogenization process, the material homogenization pressure should generally not exceed 2000bar. The high-pressure homogenizer allows overload operation to a certain extent. The equipment can run at 20% overpressure for a short time. After that, the control box circuit will automatically turn on the cut-off protection function to stop the equipment from running. After 30 seconds, it can be turned on and work again.

If the pressure cannot rise during the homogenization process, it means that the upper one-way valve is blocked, just use a thin iron wire to pass the ball valve.

2. What to Do When the Sample in the High-pressure Homogenizer Contains Air Bubbles?

A high-pressure homogenizer with a dynamic homogenization valve allows the sample to contain air bubbles or to empty the sample.

When the sample contains air bubbles or goes empty, the homogenizing valve stem and valve seat will collide to a certain extent during the homogenization process, which will cause great wear on the valve stem and valve seat, especially for the manually adjusted homogenizing valve, not only It is easy to cause the homogenizing valve to be worn, and even directly lead to the fragmentation of the homogenizing valve and make it unusable. In addition, it will cause great noise during the homogenization process.

The dynamic homogenizer valve will reduce its damage and noise better, but it is generally recommended to avoid the long-term use of samples containing a large number of air bubbles and the occurrence of empty samples in the pipeline, which can effectively prolong the service life of the homogenizer valve.

3. What to Do If the Liquid Leaks in the High-pressure Homogenizer?

There are no o-rings or gaskets in the entire sample path of the high-pressure homogenizer, and all face seals are precision-machined metal-to-metal or metal-to-ceramic seals, which generally do not leak liquids.

However, if it is installed improperly, if the sample tank and the one-way valve are not fully buckled, or if a component is not installed properly after disassembly, it will cause liquid leakage. At this time, you only need to check the pipeline and install each component correctly in strict accordance with the requirements of the installation manual.

In addition, when the sample channel is flushed with air and pressure, if the sample tank is not completely covered, the liquid will be flushed out of the sample tank due to the action of air pressure, resulting in the leakage of the sample liquid. This will not affect the homogenization process but will stain the entire external piping, affecting the aesthetics and maintenance of the machine.

If the sample is poisonous and harmful, it will endanger and pollute the operating environment and operators. In this case, the above phenomenon can be avoided by simply tightening the sample tank and then flushing the sample passage with air and pressure.