Accurate and precise Pharmaceutical analysis methods are essential for detecting impurities, quantifying active ingredients, and ensuring compliance with regulatory standards. Among the various analytical techniques, the Atomic Absorption Spectrophotometer (AAS) stands out for its sensitivity and specificity in detecting and quantifying metal elements in pharmaceutical samples.

Principles of AAS

Atomic Absorption Spectrophotometer (AAS) operates on the principle of atomic absorption. It measures the concentration of metal elements by detecting the amount of light absorbed by their atoms. When a sample is introduced into a flame or graphite furnace, the analyte is atomized, and the resulting ground-state atoms absorb light at specific wavelengths emitted by a hollow cathode lamp containing the element of interest. The amount of light absorbed is directly proportional to the concentration of the metal element in the sample.

Types of AAS

There are two primary types of AAS:

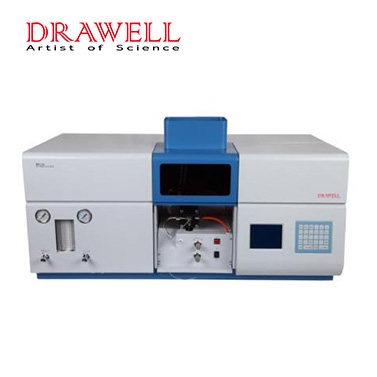

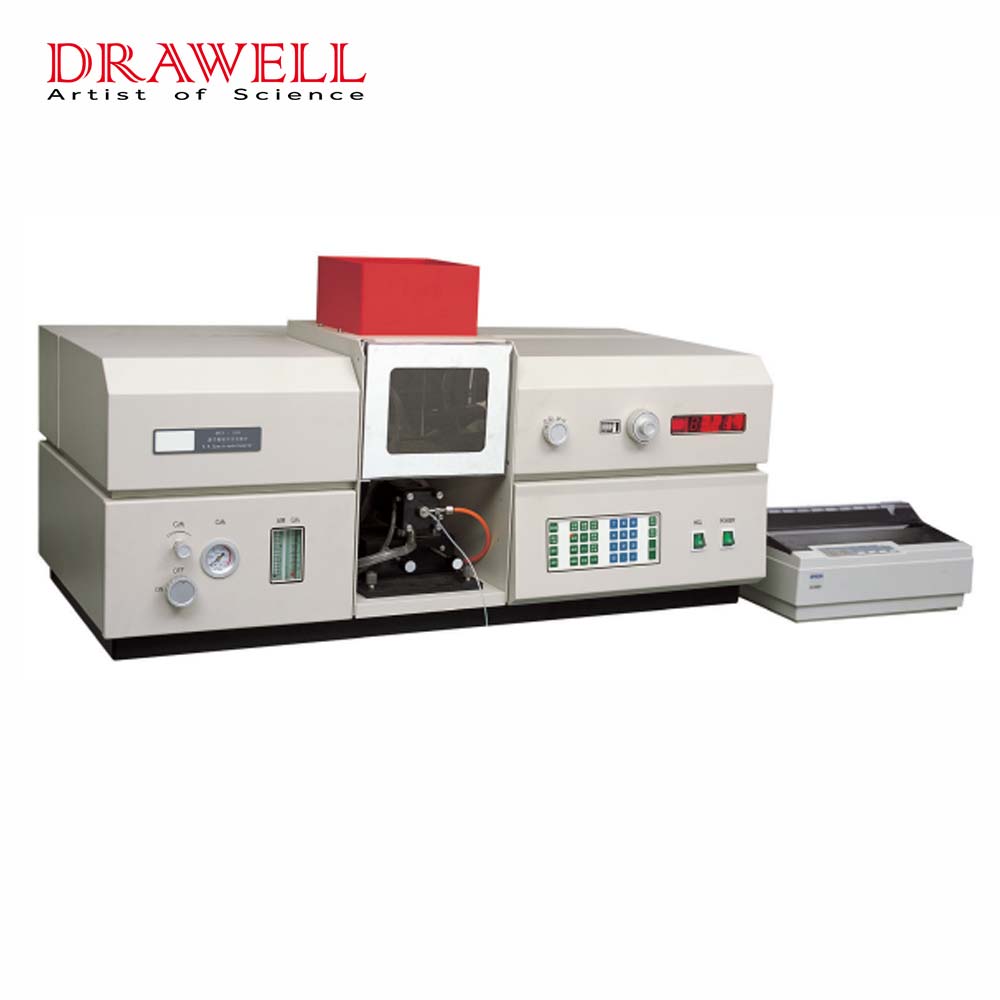

Flame Atomic Absorption Spectrophotometer (FAAS): In this method, A liquid sample is aspirated into a flame, where it is atomized. It is suitable for analyzing elements like sodium, potassium, and calcium.

Graphite Furnace AAS (GFAAS): This technique uses an electrically heated graphite furnace to atomize the sample. A small sample is placed in a graphite cuvette and dried, ashed, and atomized by controlled heating. GFAAS offers higher sensitivity than FAAS, so it’s ideal for detecting trace elements.

AAS in Pharmaceutical Analysis

The presence of metals in pharmaceuticals can significantly impact their safety and efficacy. Metals can originate from raw materials, manufacturing processes, or contamination. Therefore, accurate metal analysis is vital.

Applications of AAS in pharmaceutical

- Assay of drug compounds: AAS is used to determine the concentration of metal-containing drugs, such as those containing iron, copper, or zinc.

- Impurity profiling: Trace metal impurities can originate from raw materials, manufacturing processes, or packaging. AAS helps identify and quantify these impurities.

- Drug stability studies: AAS monitors metal content during drug storage to assess stability and predict shelf life.

- Biological sample analysis: AAS can be used to determine metal levels in biological fluids (e.g., blood, urine) for pharmacokinetic and pharmacodynamic studies.

Advantages and Limitations of AAS

| Advantages | Limitations |

| High Sensitivity and Specificity | Matrix Interferences |

| Detection of trace elements | Complex sample matrices can interfere with accuracy |

| Element-specific analysis | Requires mitigation techniques (e.g., matrix matching) |

| Precision and Accuracy | Instrumental Limitations |

| Consistent results | Sensitivity for certain elements may be low |

| High reproducibility | Regular maintenance and calibration required |

| Cost-Effectiveness | Sample Preparation Complexities |

| Lower operational costs | Requires proper sample pre-treatment |

| Suitable for routine analysis | Risk of contamination during preparation |

| Speed and Efficiency | Regulatory and Validation Challenges |

| Rapid analysis | Ensuring compliance with standards is resource-intensive |

| User-friendly instruments | Extensive documentation and record-keeping needed |

| Versatility | Limited Multielement Capability |

| Wide range of applications | Typically analyzes one element at a time |

| Less efficient for multielement analysis compared to other techniques |

Despite these limitations, AAS remains a widely used and valuable tool in pharmaceutical analysis, providing critical insights into metal content that ensure the safety, efficacy, and quality of pharmaceutical products.

Sample Preparation and Data Analysis

Sample preparation and data analysis are the critical step to make accurate AAS results in pharmaceutical analysis.

Sample Preparation

Sample preparation involves dissolving the sample in a suitable solvent and possibly performing pre-concentration steps to enhance sensitivity. The prepared sample is then introduced into the AAS instrument for analysis. Through the processes, here are three aspects to keep in mind:

1. Sample Weighing and Dilution:

Accurately weigh a representative sample of the pharmaceutical product.

Dilute the sample to a suitable concentration using a solvent compatible with AAS. Common solvents for AAS include deionized water, organic solvents, or mixtures thereof. The choice of solvent depends on the solubility of the sample and the elements of interest.

2. Digestion (if necessary):

Depending on the sample matrix, digestion with acids or other reagents may be required to break down the sample and release the elements of interest. For example, if you are analyzing a solid pharmaceutical dosage form, you may need to digest the sample in an acid solution to dissolve the excipients and release the metal analytes.

3. Filtration (optional):

Filtration may be necessary to remove undigested material that could interfere with the AAS analysis. Undigested material can cause clogging of the nebulizer in the AAS instrument and lead to inaccurate results.

Data Analysis

Data analysis in AAS involves comparing the absorbance of the sample to that of known standards. Calibration curves are used to determine the concentration of metals in the sample. Advanced software tools are often employed to ensure accurate data interpretation and reporting.

Calibration Curve Construction:

- Prepare standard solutions containing known concentrations of the element(s) of interest. These standards are used to calibrate the AAS instrument and relate the absorbance signal to the concentration of the element in the sample.

- Measure the absorbance of each standard solution using AAS. Absorbance is a measure of the amount of light absorbed by the sample at a specific wavelength.

- Plot a calibration curve of absorbance vs. concentration. The calibration curve is a linear relationship between the absorbance of the standards and their known concentrations.

Sample Analysis:

- Measure the absorbance of the prepared sample solution using AAS.

- Use the calibration curve to determine the concentration of the element(s) in the sample. By comparing the sample’s absorbance to the calibration curve, you can determine the concentration of the element in the unknown sample.

Here are some additional factors to consider during sample preparation:

Interferences:

Matrix interferences can occur when other components in the sample absorb light at the same wavelength as the element of interest. This can lead to inaccurate results. There are several ways to address matrix interferences, such as using chemical modifiers or dilution.

Standard Selection:

It is important to choose standards that are similar in matrix composition to the samples being analyzed. This will help to minimize matrix interferences.

By following these steps and considering these factors, you can ensure that your AAS samples are properly prepared and that your data analysis is accurate.

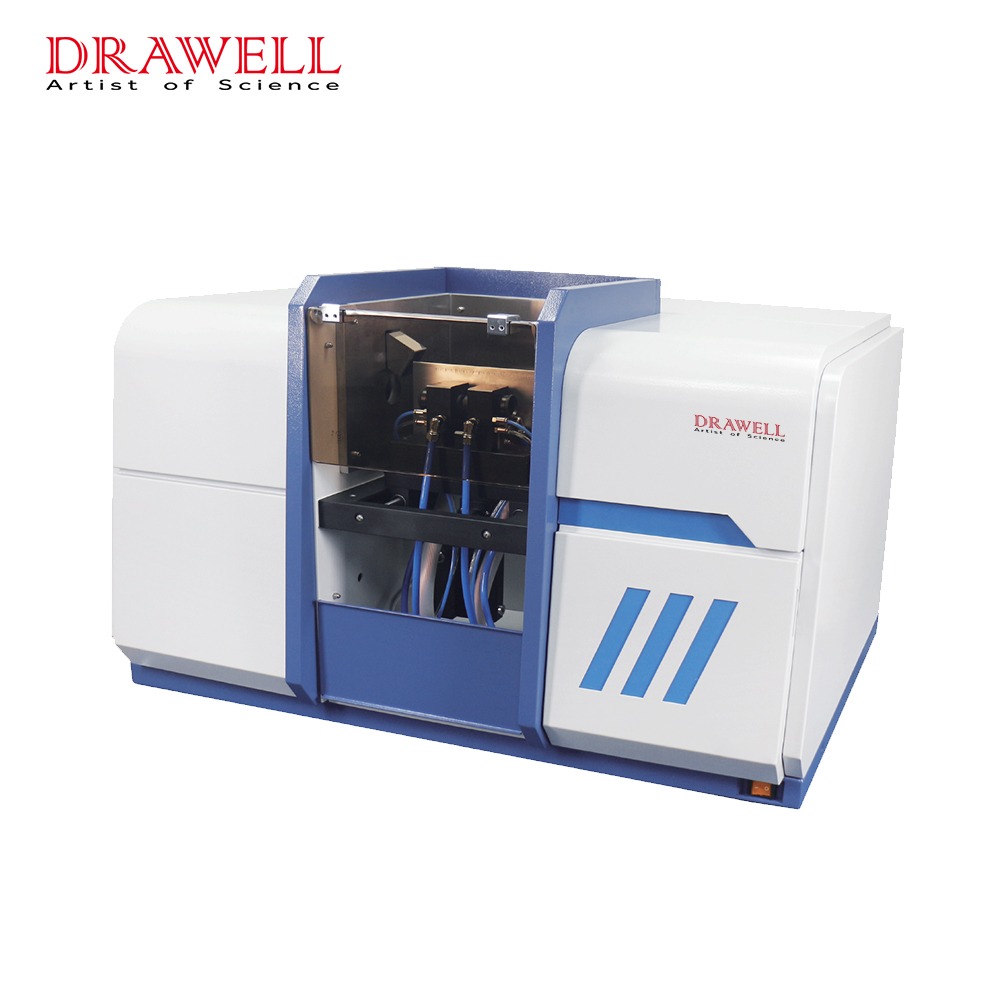

Looking for a AAS Supplier

Selecting the right AAS system is crucial for efficient and accurate pharmaceutical analysis. A reliable supplier can provide high-quality instruments, comprehensive support, and tailored solutions.

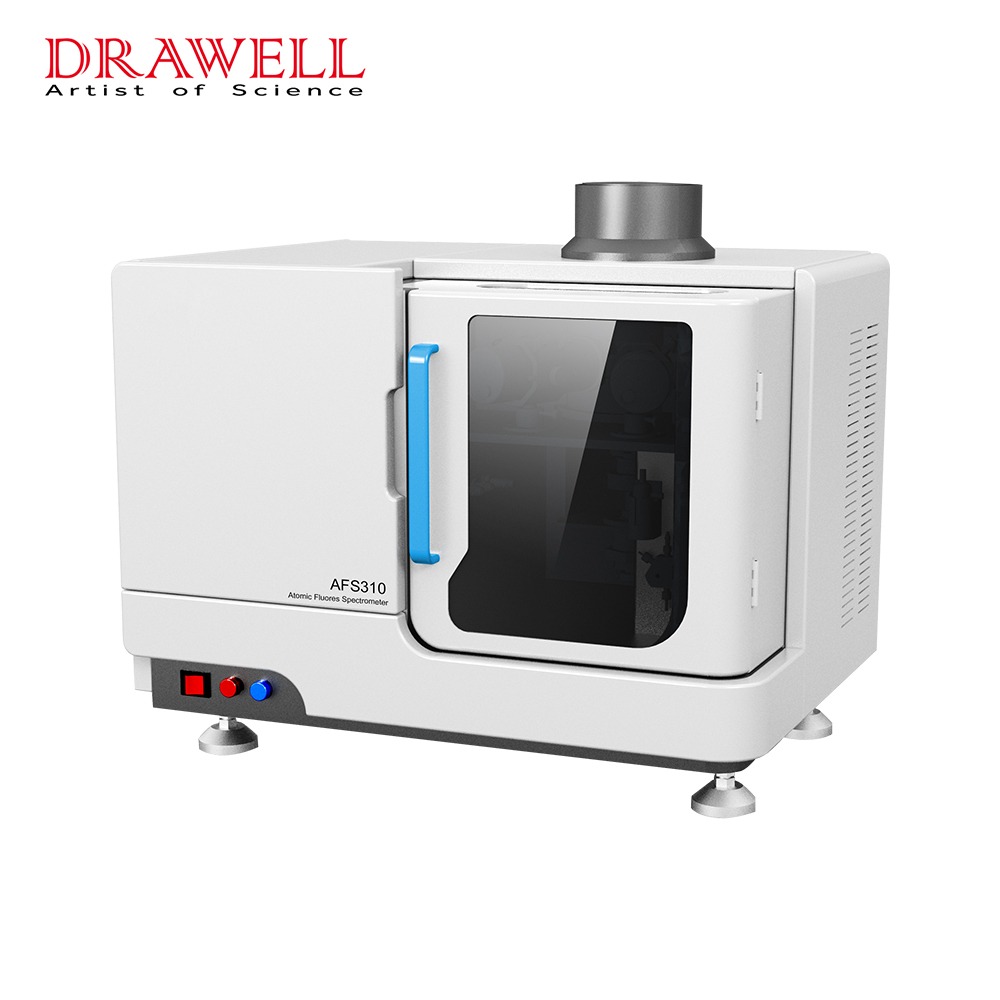

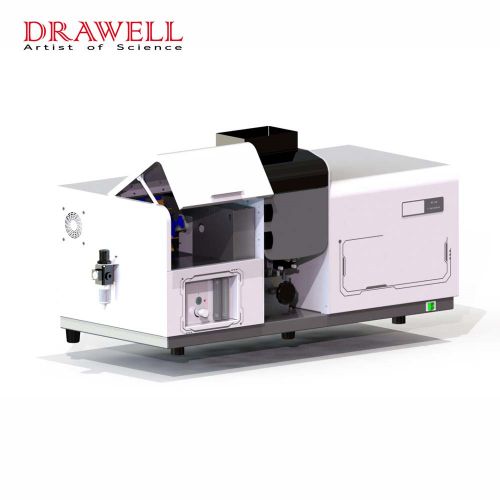

Drawell is a prominent name in the field of laboratory equipment, specializing in Spectrophotometer, Chromatography, Centrifuge and other laboratory analytical instruments. With a strong focus on research and development, Drawell offers a range of AAS models to cater to diverse analytical needs.

Drawell’s commitment to quality and customer satisfaction makes them a strong contender for your AAS requirements. By partnering with Drawell, you can access advanced technology and expert support to optimize your pharmaceutical analysis workflow.