Oil/Arc Emission Spectrometer

OILA-I Oil Emission Spectrometer is a proven means of precisely determining the elemental composition of wear metals, pollutants, and additives in lubricating oil, hydraulic oil, heavy fuel coolant, and electrolytes. It is used as both a quality control tool and a machine health monitor.

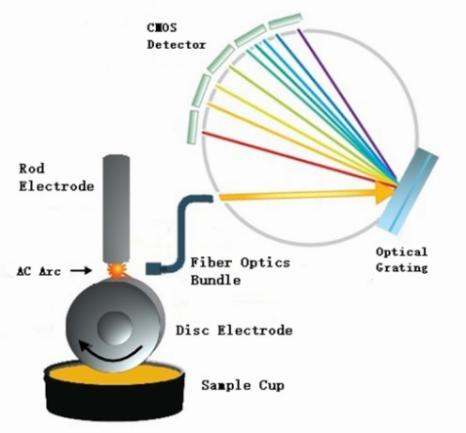

Oil Emission Spectrometer, also known as the rotating disc Electrode Atomic emission spectrometer (RDE-AES), is a standard analytical instrument for oil element detection recognized in the global market. It is specially used to accurately quantify the composition of trace elements in various industrial oils and liquids.

OILA-I provides simultaneous multi-element analysis in tens of seconds without using gases and cooling water. It is an effective tool for preventive maintenance of equipment.

AES-8000 Arc Emission Spectrometer adopts high-sensitivity CMOS as the detector, and realizes full-spectrum acquisition within the band range. It can be widely used in geology, non-ferrous metals, and chemical industries. It can directly analyze powder samples without sample dissolution, which is an ideal instrument solution for qualitative and quantitative analysis of trace and trace elements in insoluble powder samples.

Features of Oil Emission Spectrometer

- Fast and Easy to Operate

- No sample preparation required without the sample dilution or preheating required by other technologies

- No gases and cooling water required

- Tens of seconds analysis time

- Minimal training/background required to operate

- No highly skilled or trained users are required

- Stable and Reliable Structure

- Classical Pashen-Rungel optical path structure

- High precision multi-CMOS acquisition system

- Full spectrum measurement while ensuring good resolution and accuracy

- Overall structural light chamber and seismic system design to ensure stability

- Human Safety Protection Design

- Humanized excitation chamber design, more convenient sample replacement.

- Excitation chamber door safety interlock, electromagnetic shield design, to protect the safety of users.

- Intelligent Oil Analysis and Diagnosis Platform

- Integrating oil data trend tracking analysis and oil condition automatic diagnosis function;

- Multi-peak separation computing ability, a variety of digital filtering algorithm modules and adaptive background function;

- Real-time calibration, interference correction, element identification and measurement, trend analysis and diagnosis, historical tracing;

- Analysis software platform specially tailored for oil detection.

Features of AES-8000 Arc Emission Spectrometer

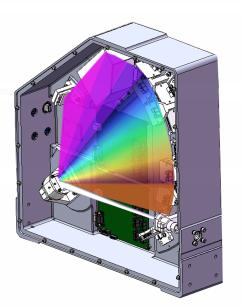

- Efficient Optical Imaging System

Ebert-Fastic optical system and three-lens optical path are adopted to effectively remove stray light, eliminate halo and chromatic aberration, reduce background, enhance light gathering ability, good resolution, uniform spectral line quality, and fully inherit the optical path of a one-meter grating spectrograph The advantages.

- Compact optical structure and high sensitivity;

- Good image quality, straight focal plane;

- Inverted line dispersion rate 0.64nm/mm;

- The theoretical spectral resolution is 0.003nm (300nm).

- High-performance linear array CMOS sensor and high-speed acquisition system

- Using UV-sensitive CMOS sensor, high sensitivity, wide dynamic range, small temperature drift; no need for coating, no device spectrum broadening effect, no film aging problem.

- The high-speed multi-CMOS synchronous acquisition and data processing system based on FPGA technology not only completes the automatic measurement of analytical element spectral lines, but also realizes the functions of automatic calibration of synchronous spectral lines and automatic background subtraction.

- AC and DC arc excitation light source

It is convenient to switch between AC and DC arcs. According to different samples to be tested, selecting the appropriate excitation mode is beneficial to improve the analysis and test results. For non-conductive samples, select AC mode, and for conductive samples, select DC mode.

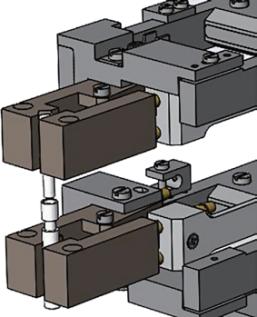

- Electrode Automatic Alignment

The upper and lower electrodes automatically move to the designated position according to the software parameter settings, and after the excitation is completed, remove, and replace the electrodes, which is easy to operate and has high alignment accuracy

- Convenient viewing window

The patented electrode imaging projection technology displays all the excitation process on the observation window in front of the instrument, which is convenient for users to observe the excitation of the sample in the excitation chamber, and helps to understand the properties and excitation behavior of the sample.

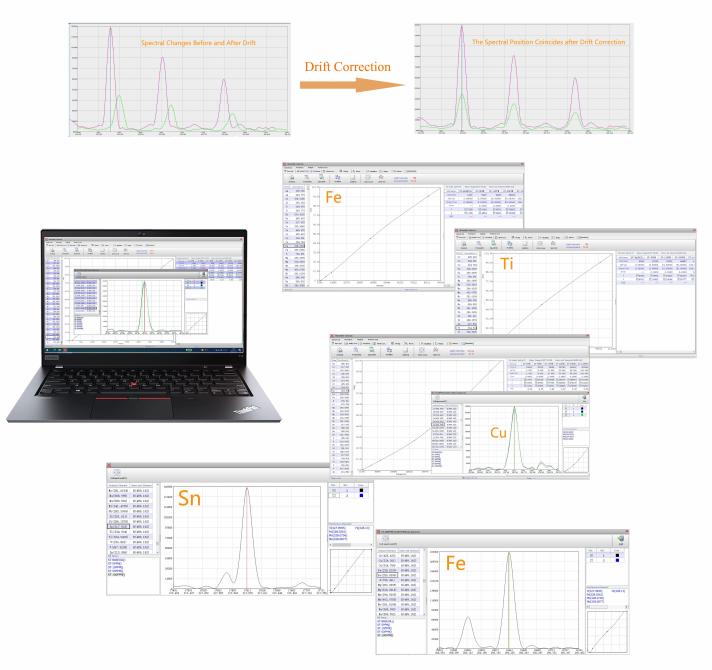

- Powerful Analysis Software

- Real-time automatic calibration of spectral lines to eliminate the influence of instrument drift;

- Background is automatically deducted to reduce the interference of human factors;

- Through the spectral line separation algorithm, reduce the influence of spectral interference;

- Automatic switching of multi-spectrum determination to broaden the range of detection content;

- The combination of two fitting methods improves the accuracy of sample analysis;

- Abundant spectral line information, broadening the application field of analysis;

- Special analysis software, suitable for different sample testing requirements.

- Convenient data post-processing function shortens the experimental process and makes data processing more flexible;

- Safety protection

- The cooling circulating water flow monitoring of the electrode clip can avoid the high temperature burning of the electrode clip;

- Activate the safety interlocking of the chamber door to protect the safety of operators.

Applications of Oil Emission Spectrometer

- Industrial Oil Monitoring: Monitor the wear condition of equipment and the pollution and aging condition of lubricating oil.

- Quality Control of Lubricants, Fuels, and Electrolytes: Process preparation and monitoring of derivative or pollutant concentration in fuel oil.

- Cooling System Monitoring: Monitor the element concentration in the cooling system antifreeze.

- Industrial Water Monitoring: Measuring power plant cooling water and turbine wash water provides unique system condition insights and ensures compliant disposal or reuse.

Applications of AES-8000 Arc Emission Spectrometer

- Simultaneous determination of Ag, Sn, B, Mo, Pb, Zn, Ni, Cu and other elements in geological samples; it can also be used for the detection of trace precious metal elements in geological samples (after separation and enrichment);

- Determination of several to dozens of impurity elements in high-purity metals and high-purity oxides, powder samples such as tungsten, molybdenum, cobalt, nickel, tellurium, bismuth, indium, tantalum, niobium, etc.;

- Analysis of trace and trace elements in insoluble powder samples such as ceramics, glass, coal ash, etc.

One of the indispensable supporting analysis programs for geochemical exploration samples.

Ideal for detection of impurity components in high-purity substances.

Conforming Standard of Oil Emission Spectrometer

ASTM D6595 Standard test method for determination of wear metals and contaminants in used lubricating oils or used hydraulic fluids by rotating disc electrode atomic emission spectrometry.

ASTM D6728 Standard test method for determination of contaminants in gas turbine and diesel engine fuel by RDE-AES.

NB/SH/T 0865-2013 Determination of wear metals and contaminants in used lubricating oils RDE-AES–Petrochemistry.

SN/T 1652-2005 Method for determination of contaminants in Import and export gas turbine and diesel engine fuel RDE-AES –CIQ.

HB 2009 4.1-2012 Determination of wear metals in aviation working fluid Part 1: RDE-AES–Aerospace.

DL/T1550-2016 Determination of metallic copper and iron content in mineral insulating oils RDE-AES–Power industry.

Specifications of Oil Emission Spectrometer

| Application | |||

| Sample type | Lubricating oil, hydraulic oil, fuel oil, grease, antifreeze, cooling water, electrolyte, etc | ||

| Analytical Element | A1, Ba, B, Ca, Cr, Cu, Fe, Pb, Mg, Mn, Mo, Ni, K, Na, Si, Ag, Sn, Ti, V, Zn, etc(extensible) | ||

| 0ptical System | Working Parameter | ||

| Optical Structure | Pashen-Rungel | Operating Temperature | -10℃~40℃ |

| Spectral Region | 201nm-810nm | Storage Temperature | -40℃~65℃ |

| Focal Distance | 400mm | Operating Humidity | 0-95%RH, condensation free |

| Detector | Highly sensitive CMOS array | Injection Volume | High-temperature oil cup |

| Temperature Control | Thermally stabilized; 37℃±0.1℃(adjustable) | Injection Mode | Rotating disc electrode |

| Power Source | Consumable | ||

| Voltage Input | 220V/50Hz | Top Electrode | Spectral pure graphite rod electrode |

| Power Consumption | ≤500W | Bottom Electrode | Spectral pure graphite disc electrode |

| Output type | AC arc | Sample Cup | High temperature oil cup |

| Mechanical Specifications | Standard Sample | ||

| Dimensions(mm³) | 500(w)×720(H)×730(D) | Standard 0il | 0#,10#,50#,100#,… |

| Weight | About 82kg | Standard Solution | 1000ppm,… |

Specifications of AES-8000 Arc Emission Spectrometer

| Optical path form | Vertically symmetrical Ebert-Fastic type |

| Plane Grating Lines | 2400 pieces/mm |

| Optical path focal length | 600mm |

| Theoretical spectrum | 0.003nm (300nm) |

| Resolution | 0.64nm/mm (first class) |

| Falling Line Dispersion Ratio | Synchronous high-speed acquisition system based on FPGA technology for high-performance CMOS sensor |

| Current range | 2~20A(AC) 2~15A(DC) |

| Excitation light source | AC/DC arc |

| Weight | About 180Kg |

| Dimensions (mm) | 1500(L)×820(W)×650(H) |

| Constant temperature of spectroscopic chamber | 35°C±0.1°C |

| Environmental conditions | Room temperature 15°C~30°C Relative humidity<80% |

Why Choose Us?

“Multiple suppliers” have always been an issue in the procurement process. Drawell as a one-stop laboratory equipment and scientific instruments supplier, can perfectly solve this problem. In addition to manufacturing our own equipment, we also represent other laboratory equipment. Our product lines are rich and diverse at competitive prices. Provide one-stop service to customers.

User Training – Training by Drawell skilled engineers about installation, debug tests, technical services, etc. It can happen in our factory in China, or at the site in the customers’ country. Cost depends on where and when the training happens.

To discuss the problem and get it resolved, online chats, real-time video calls, and remote guidance. For the after-sales stage, our online technical guidance is free and ready forever.

1 year free official warranty, including repairing quality-damaged parts, and offering replacements of selected parts (shipping cost is extra). 5% of the product price is charged for extending the warranty before the end of the official warranty.

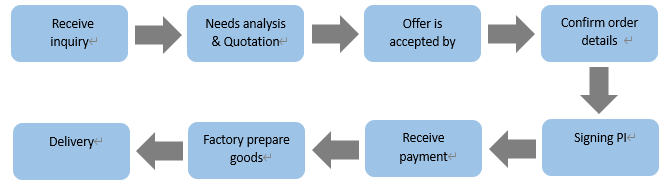

Order Process