ICP Emission Spectrometer (ICP-AES/ICP-OES)

Features | Application | Working Principle | | Why Choose Drawell | How to Install/Maintain | Other Products | FAQ

Inductively coupled plasma atomic emission spectroscopy (ICP-AES), also referred to as inductively coupled plasma optical emission spectroscopy (ICP-OES), is an analytical technique used for the detection of chemical elements. It is a type of emission spectroscopy that uses inductively coupled plasma to produce excited atoms and ions that emit electromagnetic radiation at wavelengths characteristic of a particular element. The plasma is a high-temperature source of ionized source gas (often argon). The plasma is sustained and maintained by inductive coupling from electrical coils at megahertz frequencies. The source temperature is in the range of 6000 to 10,000 K. The intensity of the emissions from various wavelengths of light is proportional to the concentrations of the elements within the sample.

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is an analytical technique used to determine how much of certain elements are in a sample. The ICP-OES principle uses the fact that atoms and ions can absorb energy to move electrons from the ground state to an excited state.

The difference between ICP-AES and ICP-OES is that ICP-AES tests each element one by one, while ICP-OES tests all elements at once.

ICP-AES

ICP-OES

Features of ICP-AES/ICP-OES

ICP-AES is often used for the analysis of trace elements in soil, and it is for that reason it is often used in forensics to ascertain the origin of soil samples found at crime scenes or on victims, etc. Taking one sample from a control and determining the metal composition and taking the sample obtained from evidence and determining that metal composition allows a comparison to be made. While soil evidence may not stand alone in court it certainly strengthens other evidence.

ICP-OES can even detect a variety of non-metals, which is a limitation of other similar techniques, including AAS and AFS. In addition, ICP-OES can be used to identify multiple elements simultaneously. This is another major advantage compared to AAS and AFS, both of which can only detect one element at a time.

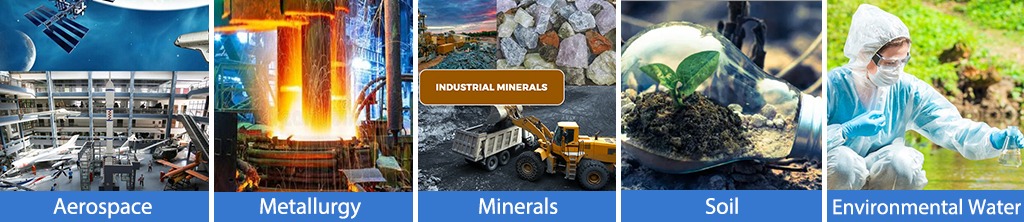

Applications of ICP-AES/ICP-OES

ICP-AES is well-suited for a wide range of sample types, including liquids, solids, and gases. It is often preferred for the analysis of complex matrices. For example:

- Geological and Mining Analysis: ICP-AES can handle geological, mining, and rare earth elements. Analysis of geological samples, including rocks, ores, and minerals, to determine the elemental composition and identify valuable or economically significant elements. Many mines use ICP-OES to check for the purity of the extracted ores of manganese, nickel, or precious metals.

- Metallurgy and Material Science: Quality control and analysis of metals and alloys in industries like metallurgy, manufacturing, and aerospace for alloy composition and impurity detection.

- Environmental Analysis: Determination of trace metals and non-metals in environmental samples such as soil, water, and air for pollution monitoring and compliance with environmental regulations.

ICP-OES is commonly used for liquid samples, making it an excellent choice for routine analyses in applications such as environmental testing, metallurgy, and quality control. For example:

- Routine Elemental Analysis: Widely used for routine analysis of various liquid samples in quality control, manufacturing, and industrial applications.

- Metallurgical Analysis: Analysis of metals and alloys in metallurgy, foundries, and manufacturing processes for quality control and material characterization.

- Environmental Monitoring: Monitoring and analyzing environmental samples, including water and soil, to detect and quantify trace elements and contaminants.

- Petrochemical Analysis: Analysis of petrochemical products, including fuels, lubricants, and chemicals, for quality control and compliance. Petrochemistry uses also ICP-OES, for petroleum refining and lubricant oil production, but also for some applications such as wear metals in oil analysis that allow preventive maintenance to be done for engines (mining trucks, airplanes, etc.).

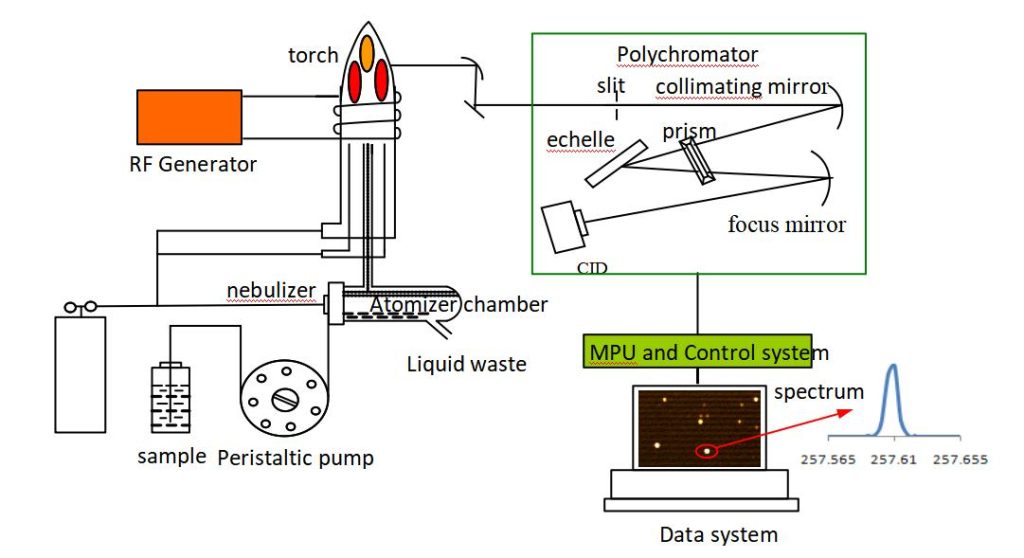

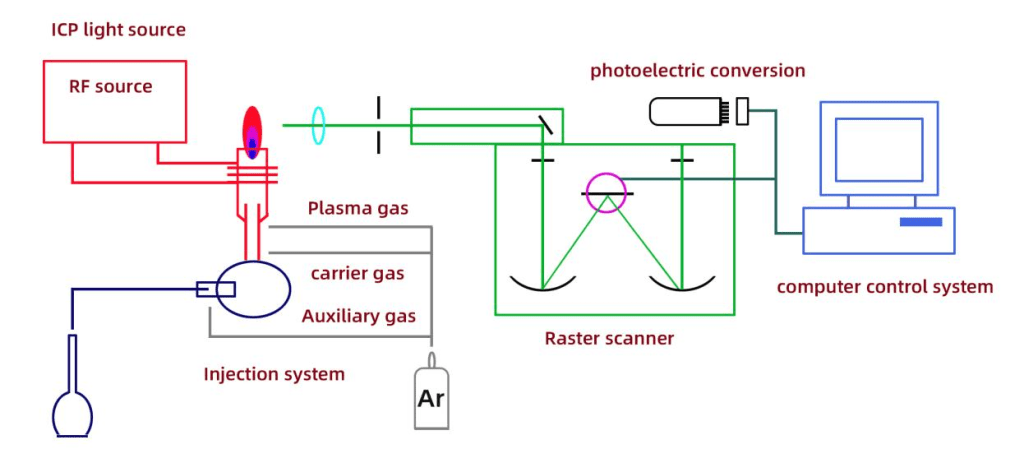

Working Principle for ICP-AES/ICP-OES

RF generator applies the high frequency power onto the tri-concentric quartz torch via induction coil to generate a high-frequency oscillating electromagnetic field; Ar is purged from the outer layer of the quartz tube and charged by HV discharging, those charged particles reciprocate in the high-frequency electromagnetic field and collide with other Ar atoms to produce more charged particles, finally generate Ar plasma(6000K~8000K) with a rise of temperature.

The aerosol generated by aqueous sample passing through the nebulizer is excited the characteristic lines of the elements under high temperature by entering the quartz torch center channel, which is correctly positioned to CID detector pixels by using a Plasma source and a polychromator for spectroscopic imaging and transform the spectral intensity into signal, transmit to the computer for data processing,finally print the result out.

How to Choose the Model?

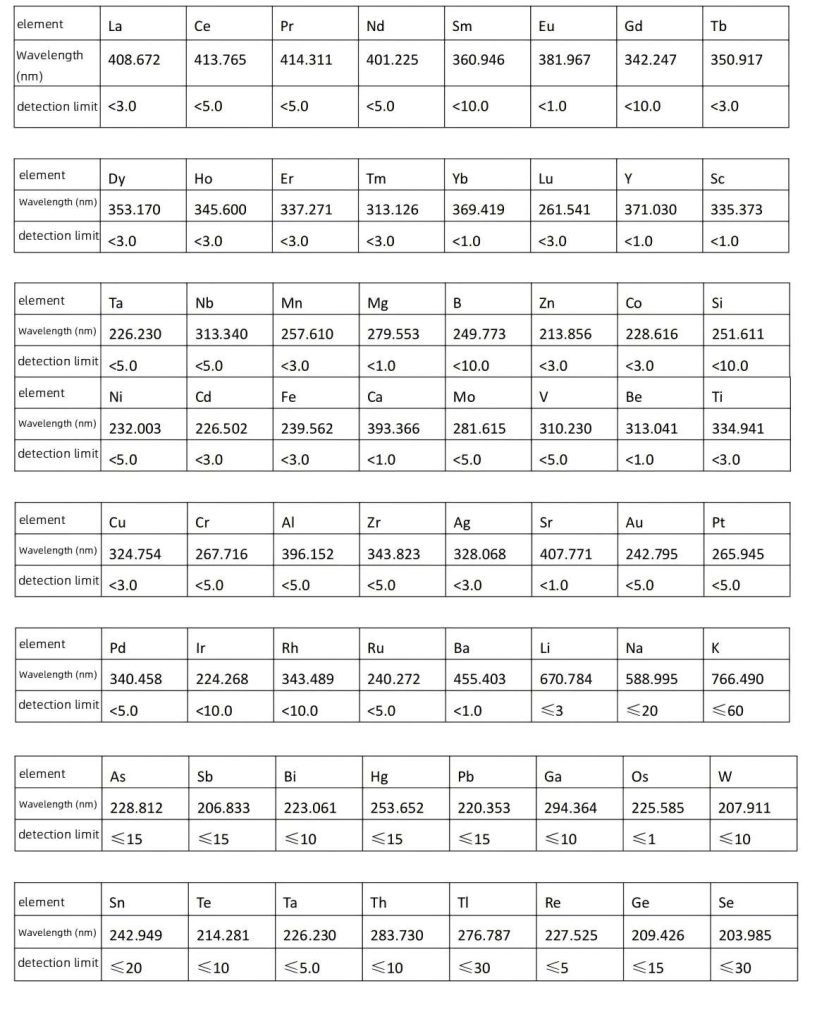

The user needs to provide the application field used, what is the sample to be tested, what elements need to be detected, what is the detection level, ppm or ppb, and so on. Then we will recommend the appropriate product model.

Why Choose Us for ICP-AES/ICP-OES?

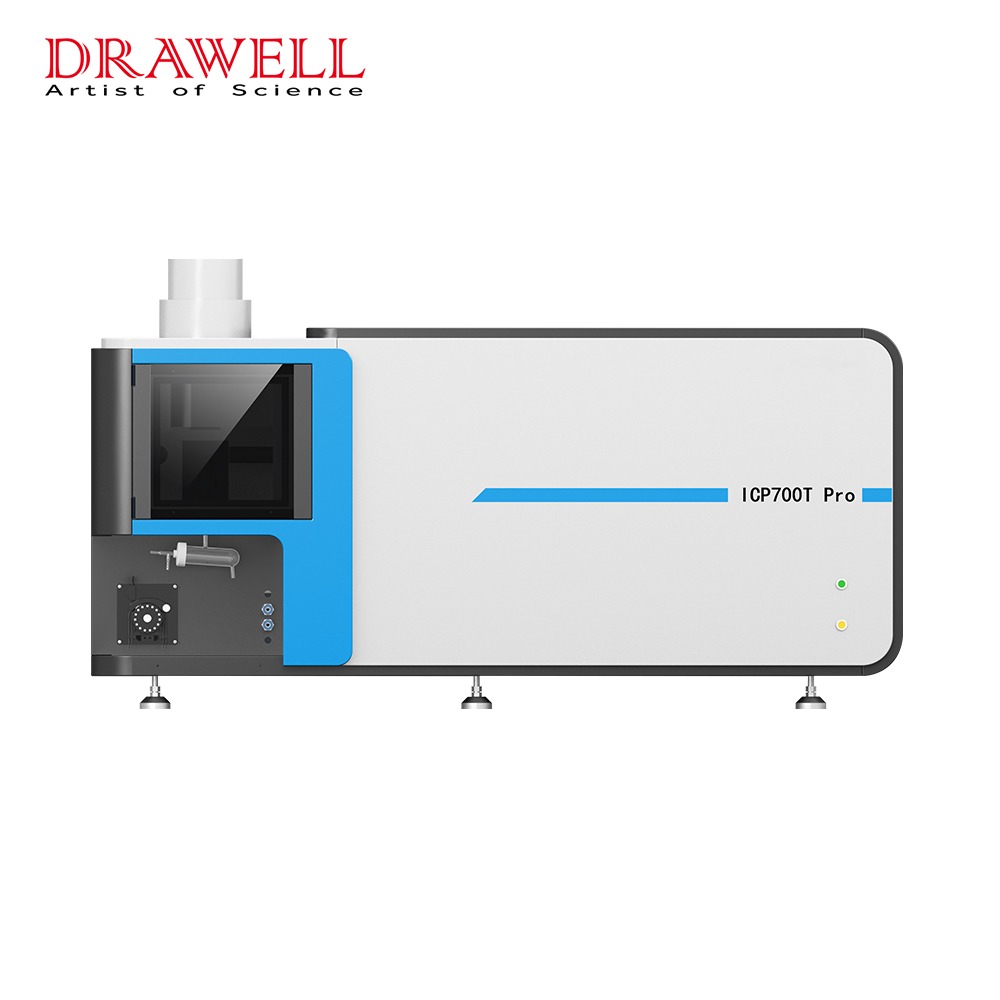

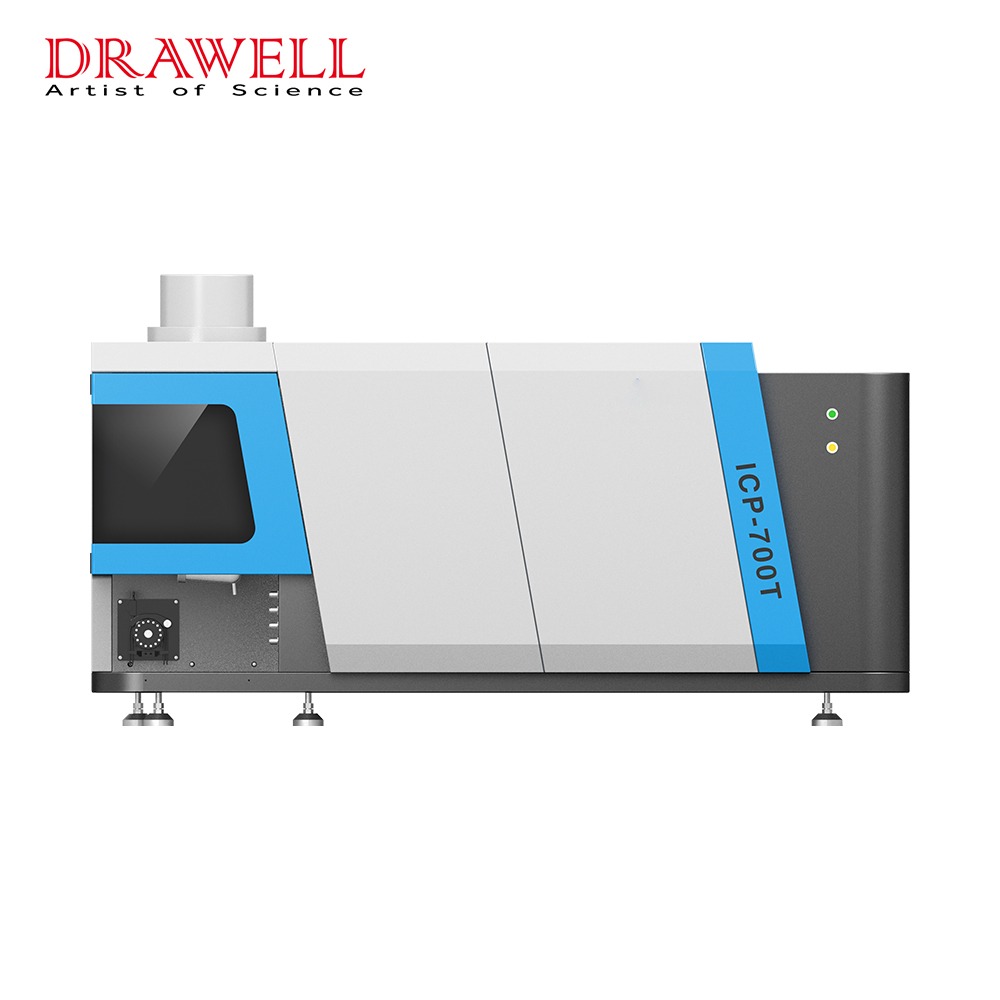

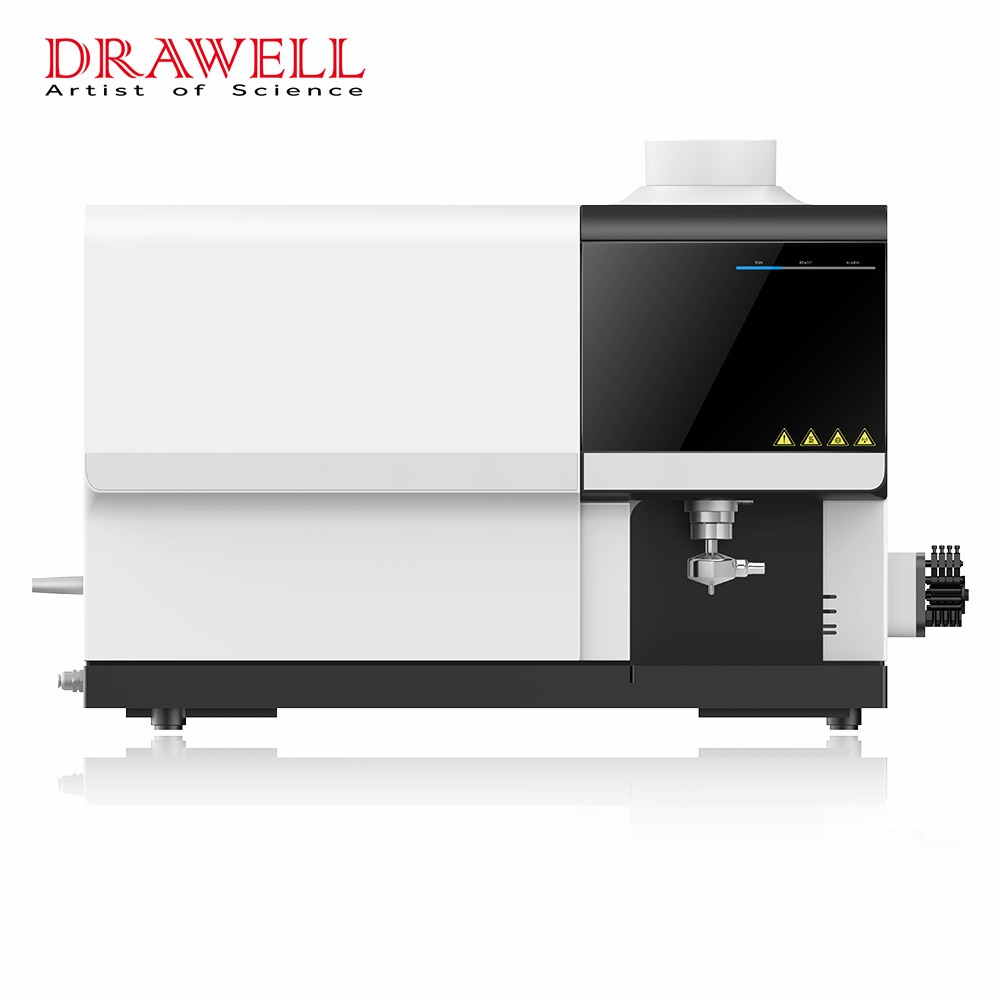

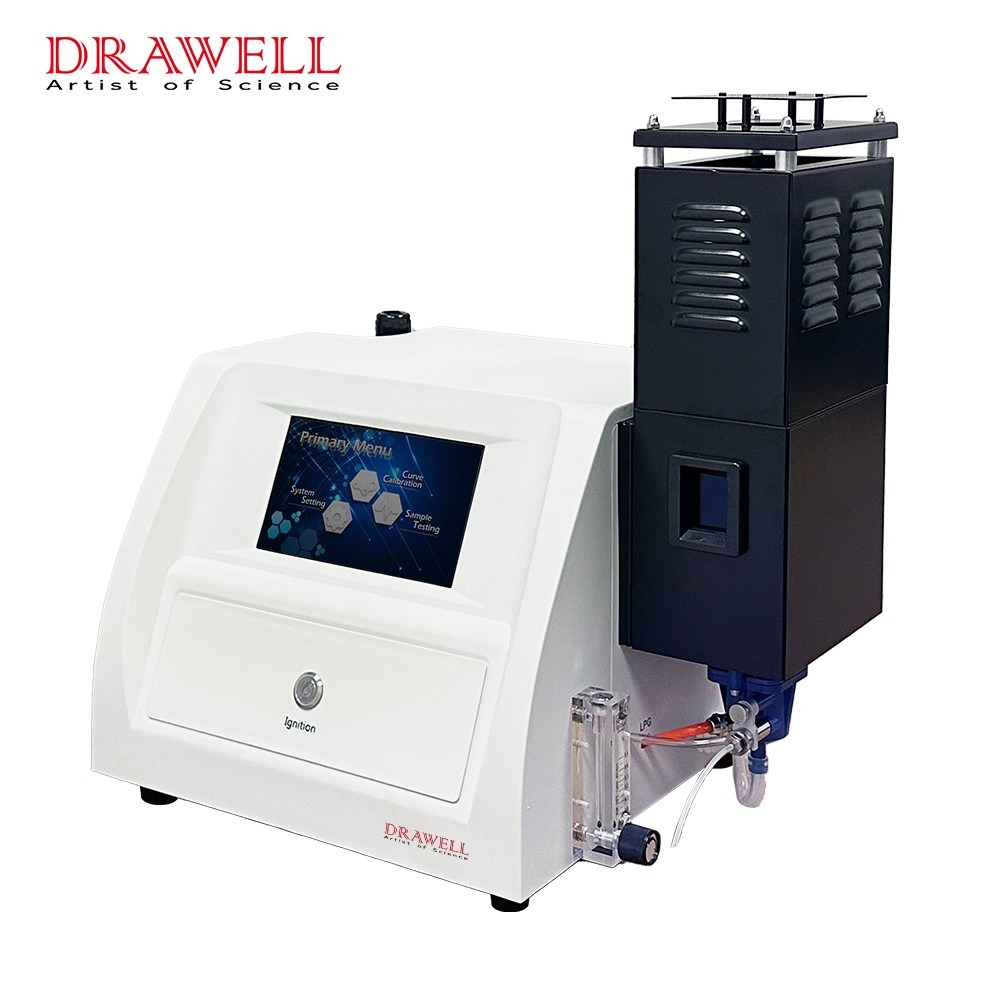

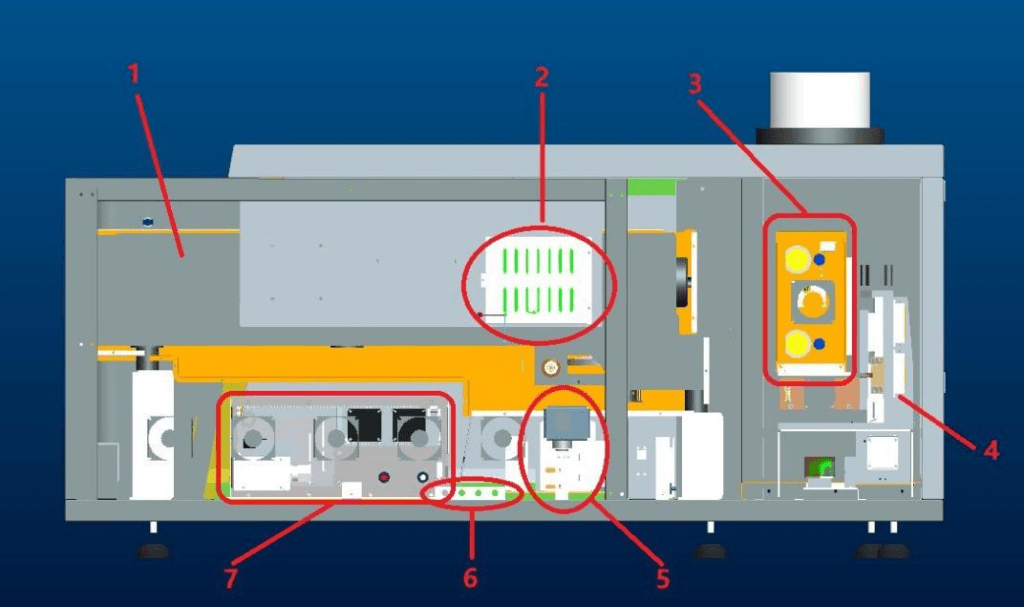

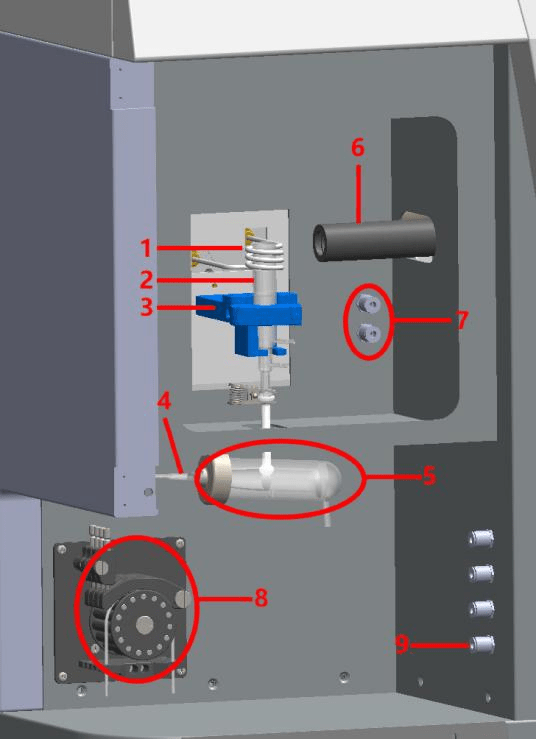

Structure Appearance and Main Components of ICP-AES

The instrument mainly consists of the following main parts: host control system, power matching system, injection system, etc. The details are as follows:

1) Internal structure diagram of the instrument

- Spectroscopic system

- Main control system

- Matcher

- Mobile platform

- Cooling the water route protection system

- Gas route module

- Solid-state RF power supply

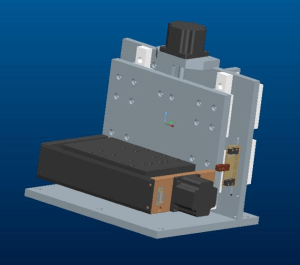

2) Automatic observation and regulation system

Automatic observation and adjustment platform: The automatic observation platform has the X-axis and Y-axis bidirectional adjustable, the computer software automatic control, used to adjust the size of the flame center position, to achieve the best observation position.

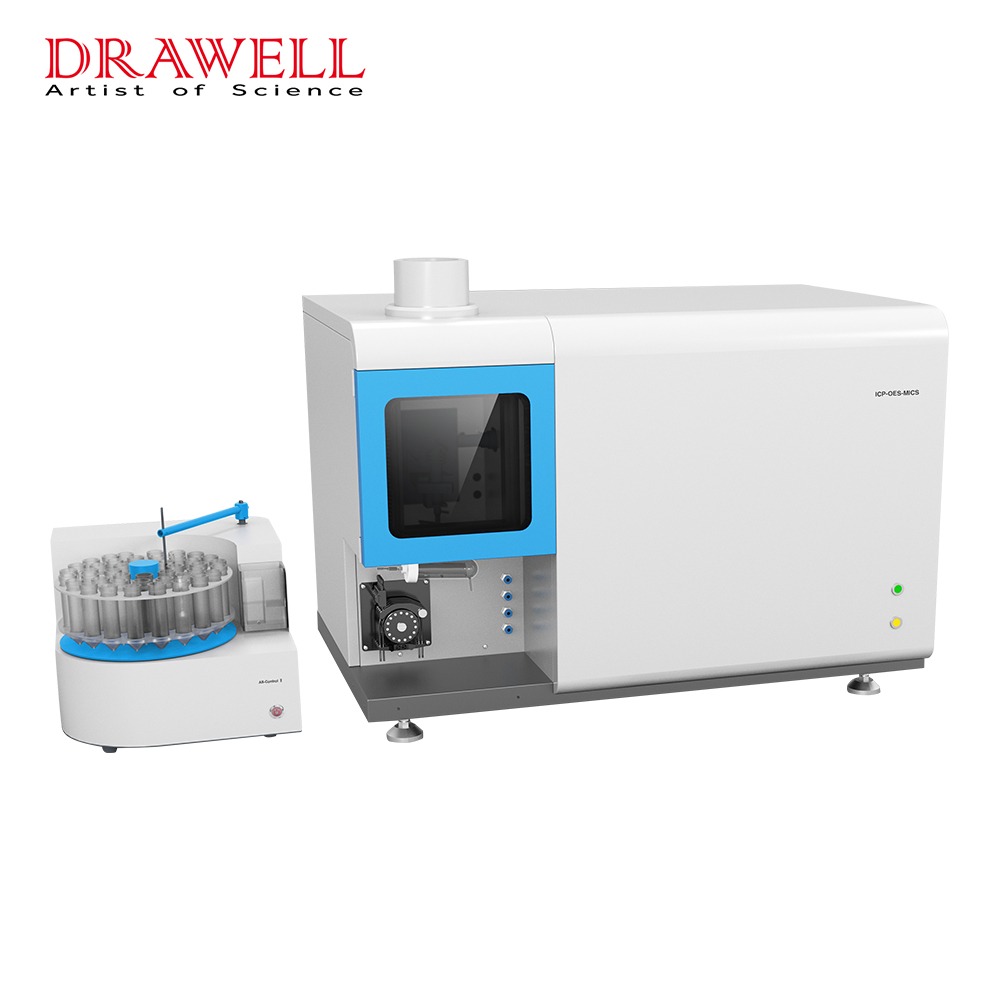

3)Sampling system (The injection system mainly includes: atomizer, double-cylinder fog chamber, plasma gas, carrier gas, auxiliary gas, torch tube and peristaltic pump.)

- high-frequency coil

- Torch tube

- Torch pipe fixation device

- Atomization device

- Atomizer chamber

- Lens cone

- Auxiliary gas and plasma gas joint

- Peristogenic pump gas inlet

- Gas inlet

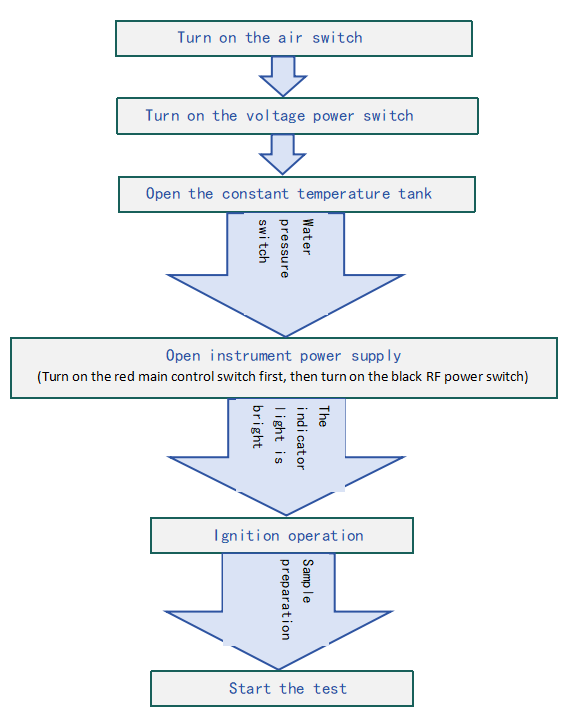

Operation Steps of ICP-AES

- Instrument operation process

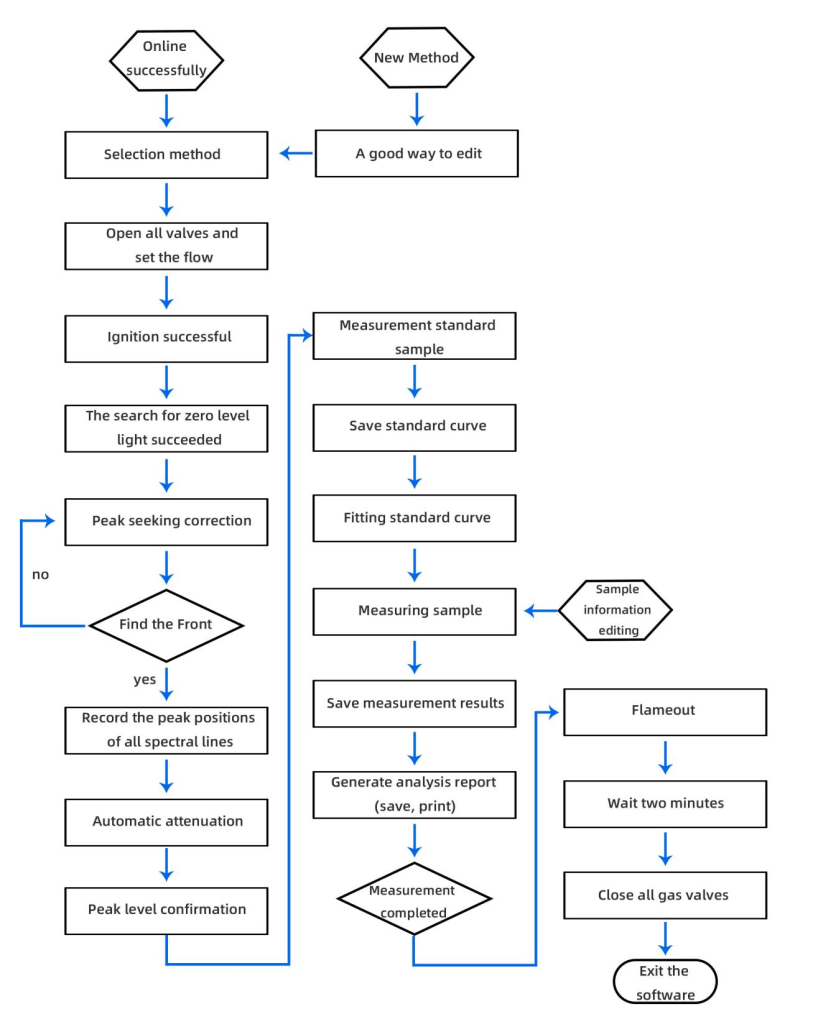

- Flow chart of the software operation

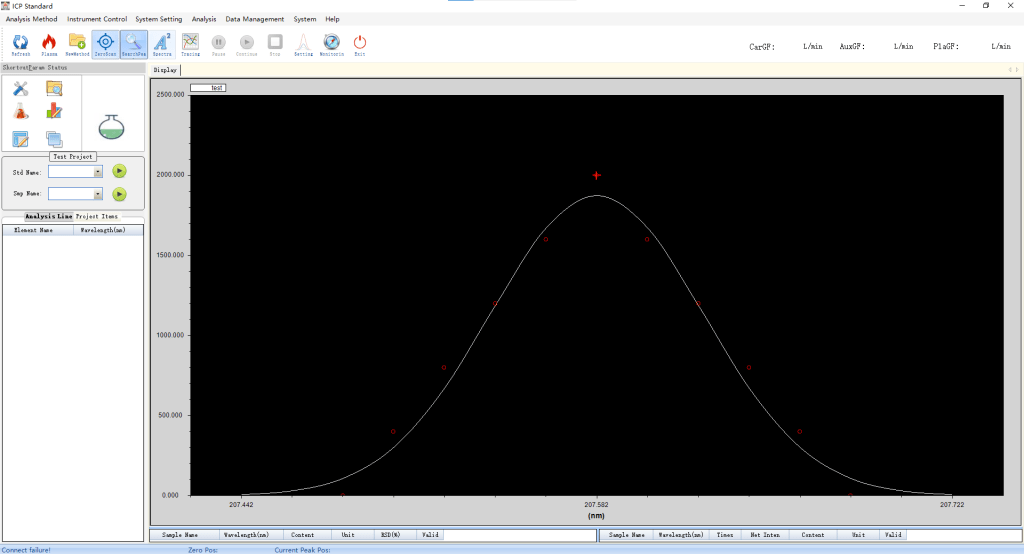

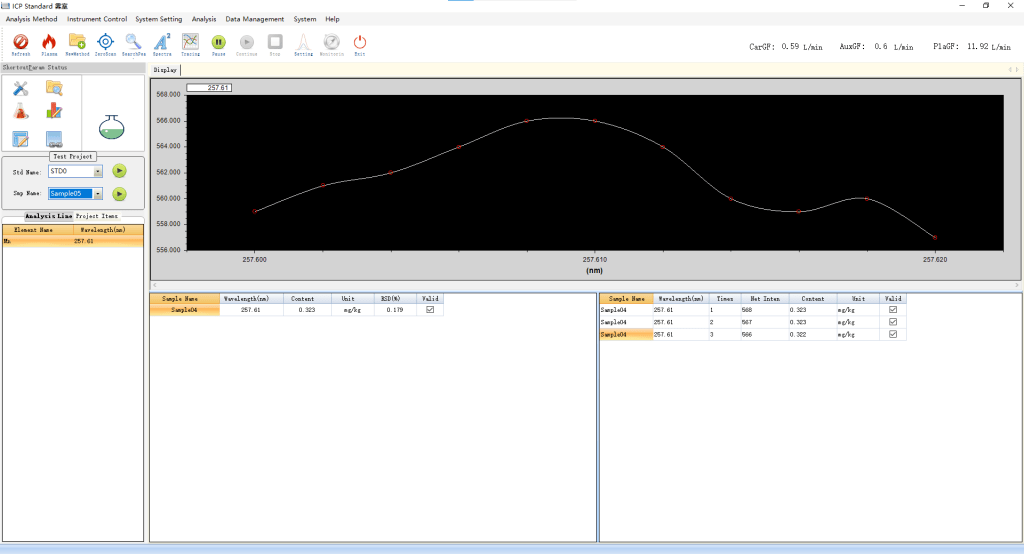

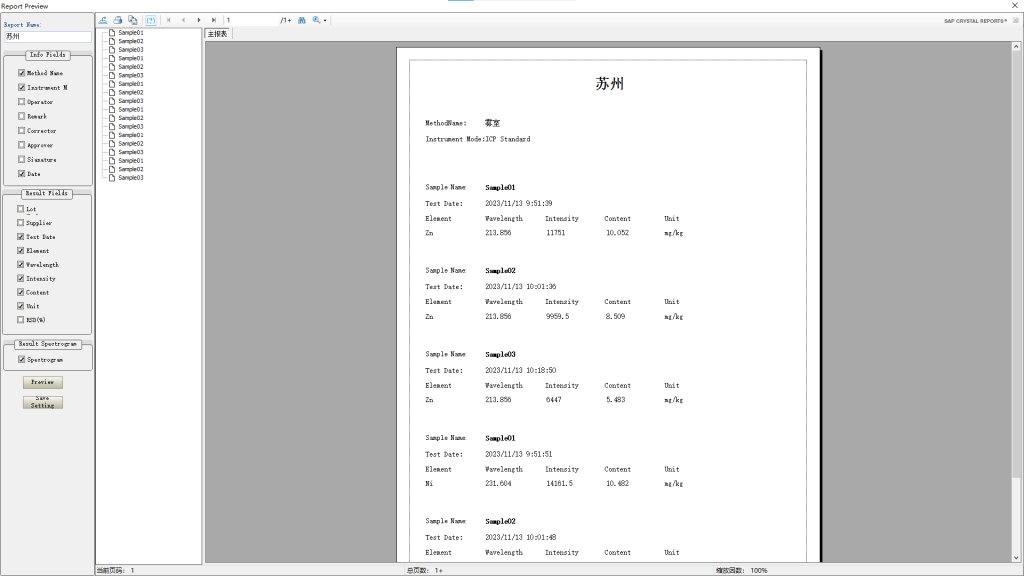

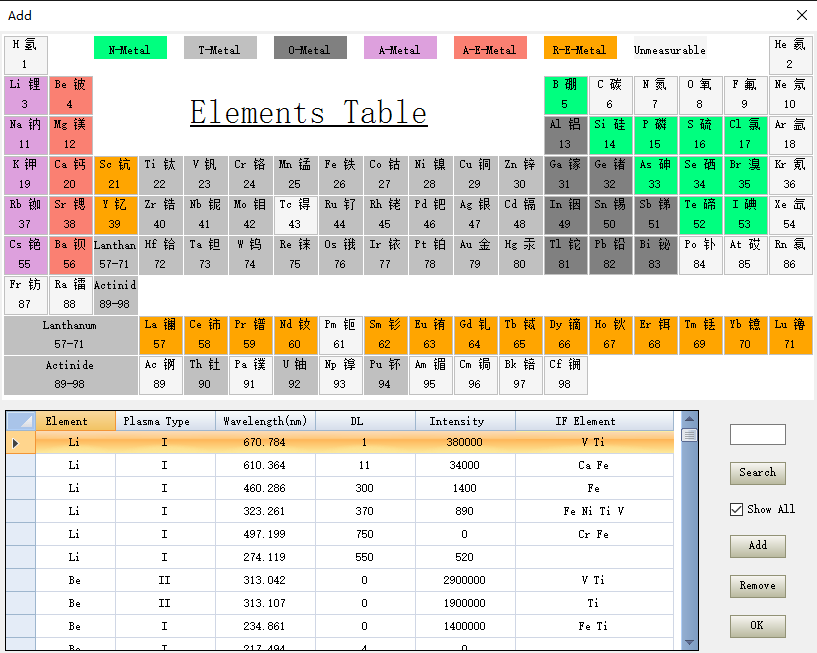

Software Interface/Test Results of ICP-AES

The main interface of the software is divided into seven parts: file, control, setting, analysis and measurement, data management, system and help.

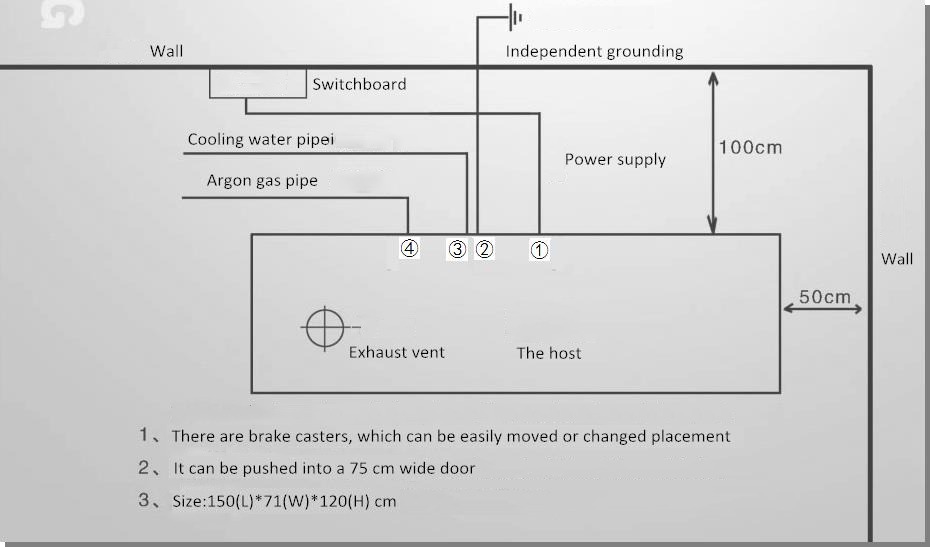

How to Install ICP-AES?

The back of the ICP-AES, from left to right are main ICP power socket, ground wire, cooling water inlet and outlet(two parts), plasma gas and carrier gas inlets.

- Schematic diagram of the installation position of ICP-AES in the laboratory.

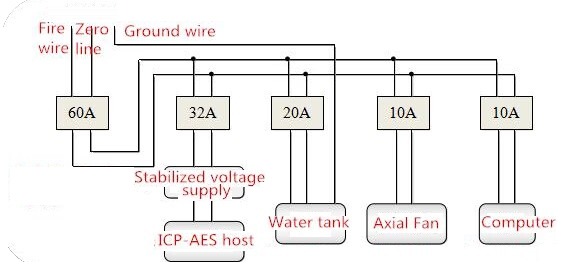

- Circuit breaker installation wiring diagram

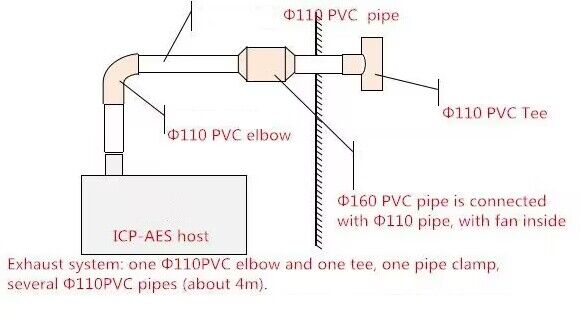

- Schematic diagram of installation of exhaust equipment

Daily Maintenance and Precautions For ICP-AES/ICP-OES

- Ambient temperature: The normal working environment temperature requirement of ICP spectrometer (25℃±3℃) (temperature change rate within 2℃/h). Relative humidity: the relative humidity should be below 70% for storage and normal operation. If the humidity is strong, please equip a dehumidifier. The room is clean, dry, free of dust, corrosive gas, acid mist, etc., and no vibration on the ground. Doors and windows are tightly sealed to prevent sand and moisture from entering. Especially after testing the sample (because it is a corrosive solution, the volatilized gas will easily corrode the instrument) is not allowed to be placed in the ICP room.

- Power lines: In order to ensure the safe operation of this instrument, the power lines capacity must be sufficient to load the voltage,otherwise excess voltage will affect the life of the instrument.

- Precautions for Turn On/Off: Before turn on the measurement, you need to make various preparations in advance to avoid damage to the instrument frequently during a period of time. Because when the instrument is turned on, the instantaneous strong current impact can easily cause the tube filament to fuse, or short-circuit between electrodes, and cause premature aging of the tube. Therefore, as far as possible to minimize the shutdown during use.

- Argon pressure: the pressure of argon used in ICP-AES must be controlled at 0.25MPa—0.3MPa and kept stable. To check whether the plasma gas pressure is stable within 5-10 minutes after each opening. If there is any pressure fluctuation, the operator must immediately turn off the gas and check the cause, and then turn on the gas again after troubleshooting.

- Parts installation: To replace the parts installed on the working coil( such as the torch), the high-voltage power supply must be turned off(or the ICP power supply). When performing maintenance on the power box, the operator must shut it down for 30 minutes before you can handle it, so as to avoid the high-voltage electric energy stored in the high-voltage filter capacitor from discharging, causing equipment or personal injury.

2.jpg)