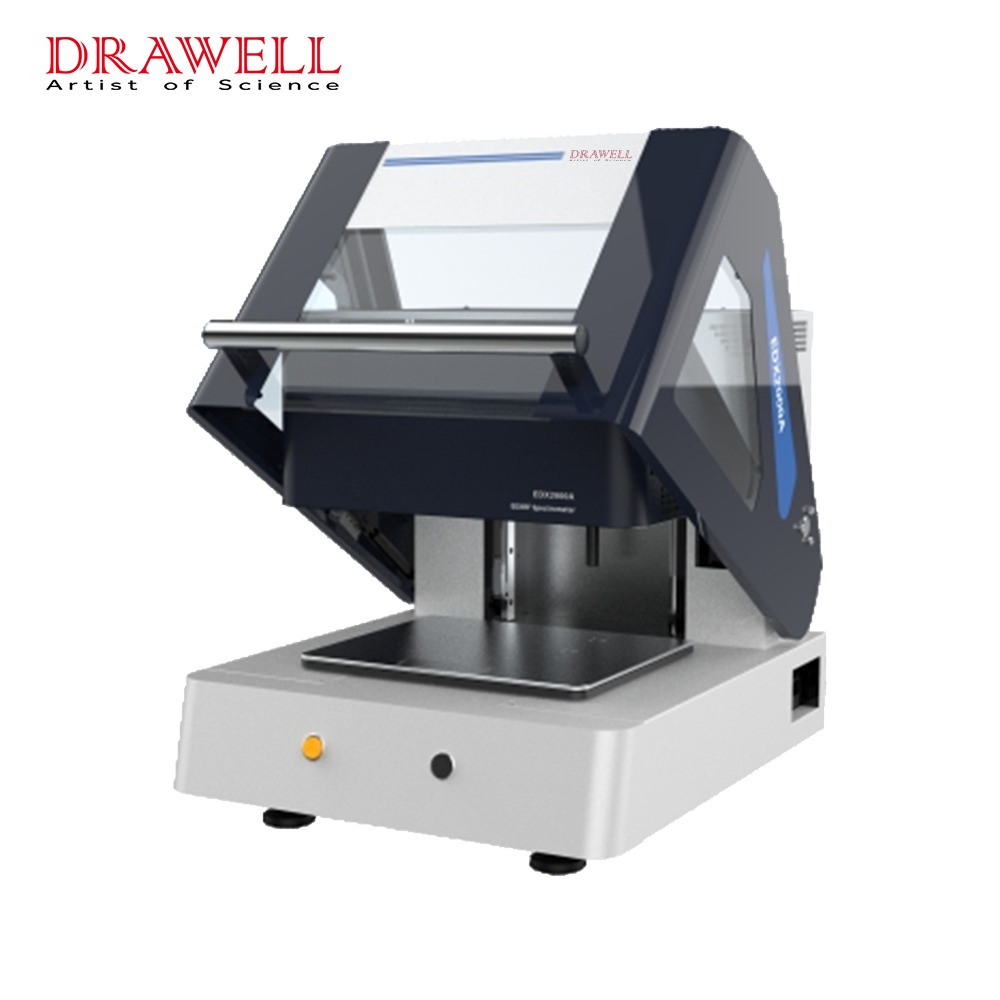

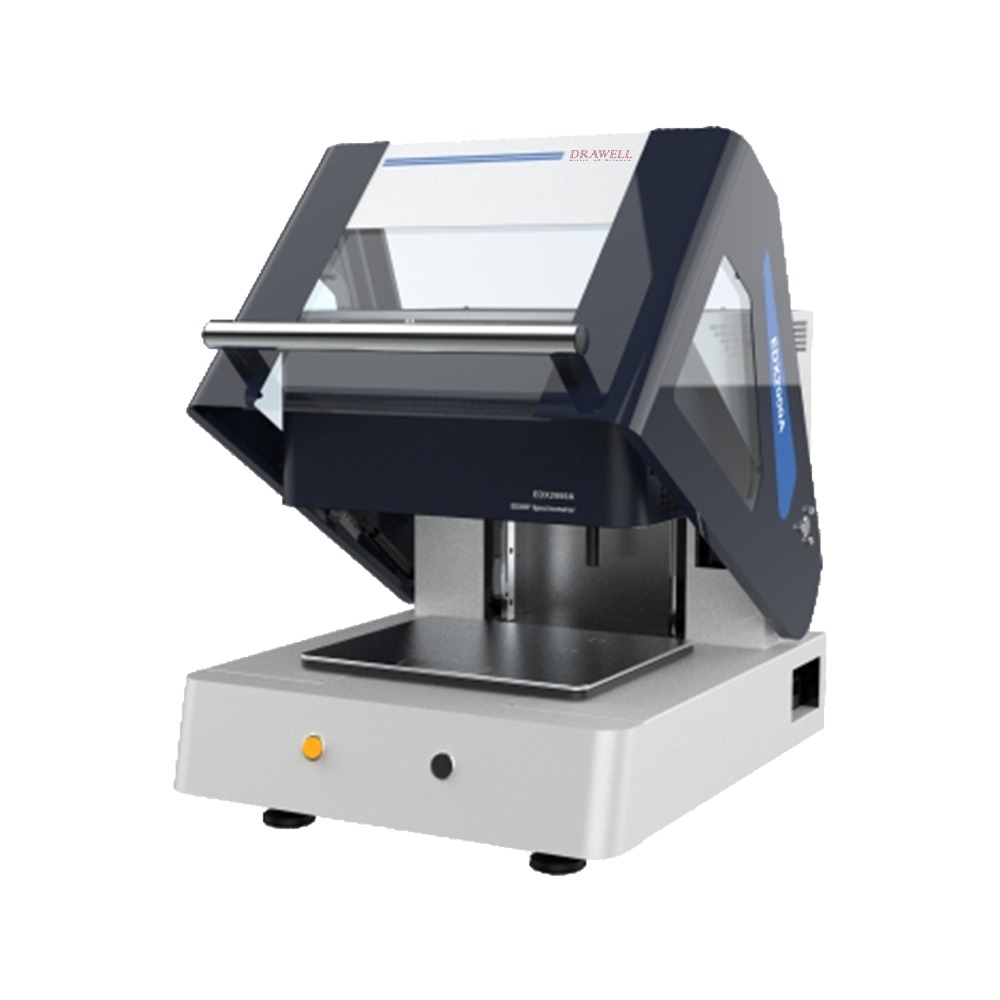

Desktop X-Ray Fluorescence Spectrometer (XRF)

What is Desktop X-Ray Fluorescence Spectrometer (XRF)?

X-ray fluorescence (XRF) uses X-rays and fluorescence technology. When primary X-rays are irradiated on the sample to be tested, the secondary X-rays generated are called X-ray fluorescence. The composition and energy of the substance are analyzed by analyzing the wavelength and energy of the fluorescence.

The High-Performance Desktop XRF is equipped with globally advanced analysis technology, an intelligent vacuum system, and developed electronic technology. Combined with a low-energy tube vacuum system and low background technology. It efficiently reduces testing interference and improves energy resolution of Mg, Al, Si P, and other light elements in geology and minerals, and accordingly an ideal choice for quality control in large and middle-scaled enterprises.

Drawell provides you with two types of XRF – Handheld XRF and Desktop XRF.

Features of Desktop XRF

- High precision, fast testing speed, easy operation, etc.

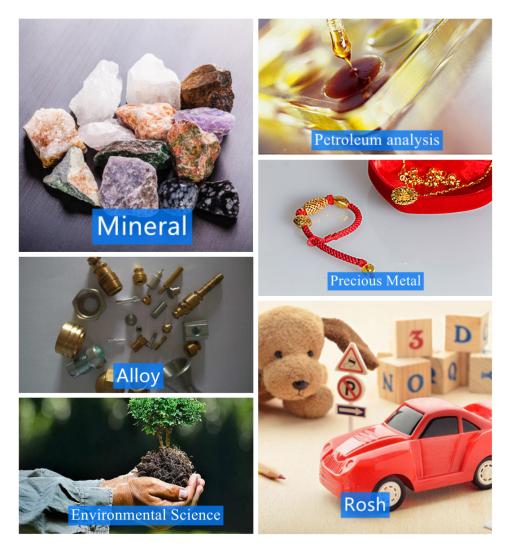

- Bear several testing analysis modes, including alloy soil precious, and RoHS.

- Testing samples can be solids, liquids, and powders.

- Highly efficient super-thin window-ray light tube, which is specially developed for mineral testing, reaches the international advanced level.

- Automatic switch of collimator and filter according to different samples, eliminating the troublesome manual operation.

- Software protection: Automatic shut-down of software program when opening the cover during testing.

- Principle of Wavelength Dispersive Spectroscopy.

Specifications of Desktop XRF

| Picture | Model | Main Application |

| DW-EDX3000 | Energy Dispersive X-Ray Fluorescence Spectrometer, for all precious metals in gold jewelries |

| DW-EDX3600H | Mineral analyzer(light elements)Na to U |

| DW-EDX 800 | Gold XRFAnalyzer (Au, Zm, Cu, Ni, Zn in gold jewelries) |

| DW-WDX200 | Wavelength Dispersive X-ray Fluorescence Spectrometer, for cement testing instrument |

| DW-NP-5010 | Energy Dispersion X-ray Fluorescence Spectrometer, any element from Na(11)-U(92) |

| DW-BP-9010 | Metal, ore, cement testing, any 9 or 10 elements from 11Na~92U |

| DW-EDX6000C | Ore, alloy, precious metal, soil, cement analysis. Fluorine (F) to Uranium (U) |

| EDX2000A | Semiconductor, chip and PCB, metal coating thickness analysis. Elements detection range from 13AI~92U, measurable range of coating from 3Li~92U. |

Applications of Desktop XRF

- Environmental protection: analysis of heavy metals in soil; analysis of harmful metals in paints, paints, pigments, and plastics

- Metal identification, scrap metal classification

- Petrochemical industry, catalyst, and additive element analysis

- QC/QA in metal production, casting, etc.

- Pharmaceutical Biomedicine

- Geological and mineral fields: mines, ore analysis, mineral analysis, beneficiation process control

- Material field: component analysis and quality control of refractory materials, glass, ceramics, cement, etc.

Different Applications of Spectrophotometer

| Application | Spectrophotometer Type | Picture | Model |

| Gold in Ore, Metallurgy. Geology, Mining, Petroleum. Cement, Soil, Medicine, etc. |

AAS |  |

DW-AA320N |

| Alloy, Mineral, Precious Metal, RoHS, Catalyst etc. | XRF |  |

DW-NP-5010 |

|

EDX3600H | ||

|

TrueX 900 | ||

|

EDX800 | ||

| MaterialsAnalysis, Geology, Petrochemicals, Biology, Cement, Soil, Cosmetics, Food, etc. |

ICP-AES |  |

ICP700T |

| Foundry, Steel, Metal Recovery, Smelting, MilitaryAerospace, etc. | Full Spectrum Direct Reading Spectrometer |  |

DW-TY9000 |

How to Choose the Desktop XRF Model?

The user needs to provide the application field used, what is the sample to be tested, what elements need to be detected, what is the detection level, ppm or ppb, and so on. Then we will recommend the appropriate product model.

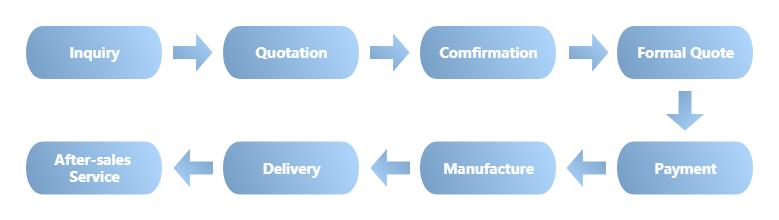

Order Process of Desktop XRF

Why Choose Us for XRF?

“Multiple suppliers” have always been an issue in the procurement process. Drawell as a one-stop laboratory equipment and scientific instruments supplier, can perfectly solve this problem. In addition to manufacturing our own equipment, we also represent other laboratory equipment. Our product lines are rich and diverse at competitive prices. Provide one-stop service to customers.

User Training – Training by Drawell skilled engineers about installation, debug tests, technical services, etc. It can happen in our factory in China, or at the site in the customers’ country. Cost depends on where and when the training happens.

To discuss the problem and get it resolved, online chats, real-time video calls, and remote guidance. For the after-sales stage, our online technical guidance is free and ready forever.

1 year free official warranty, including repairing quality-damaged parts, and offering replacements of selected parts (shipping cost is extra). 5% of the product price is charged for extending the warranty before the end of the official warranty.

Customer Feedback of XRF