Features and Advantages

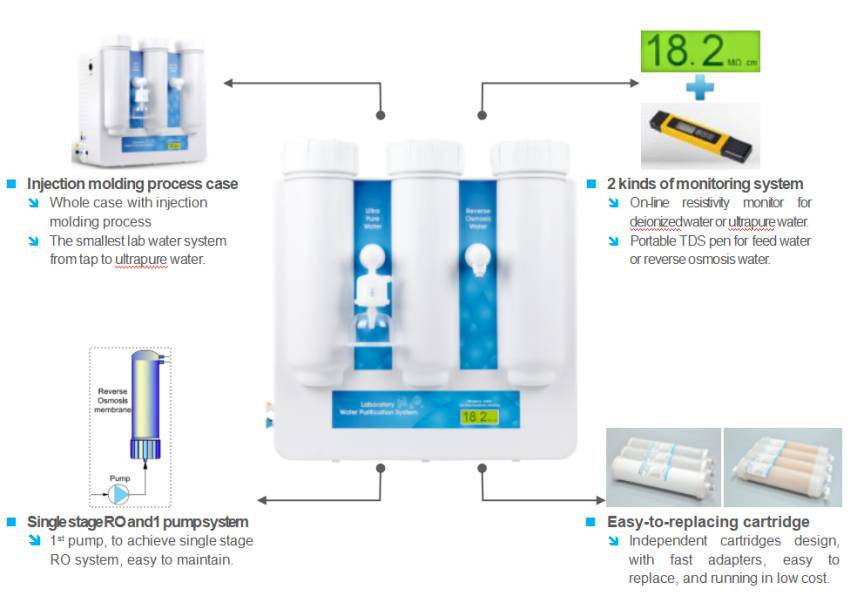

- The smallest and most compact lab water system from tap to ultrapure water, integrating pretreatment, RO, DI, UV, UF and terminal filter into one.

- Whole case with one time injection molding process, material: polypropylene, avoid rusting and keep clean, to meet GLP standard.

- Top cap of pretreatment in the case can be rapidly opened to replace the cartridges without opening the case.

- System automatically works, with electronic pressure sensor and microcomputer controlling.

- Automatic stop without water, automatic stop when water tank full, automatically cutting off water when pump stopping, guaranteeing 24 hours’ work.

- Auto self-flushing of RO membrane function, extend RO membrane’s life.

- On-line resistivity monitor, with apheliotropic LCD display, to detect the quality of deionized or ultrapure water.

- Attached portable TDS (total dissolved solid)/conductivity test pen, with dry cell design, to detect the quality of feed water and RO water.

- External water tanks is optional to meet different need and assure ample water-supply.

- Tube and adapter with NSF authorization and top quality, reduce TOC level and assure ultrapure water’s quality.

- Long-life pretreatment (including PP fiber, and active carbon cartridge), effectively protect RO membrane.

- RO module with DOW’s membrane, ensure long life, stable operation and high desalinization rate.

- 4 independent ultrapure cartridges with DOW’s top polishing resin, ensure ultrapure water’s quality up to 18.2 MΩ.cm, with the lowest TOC level and running cost.

- Double wavelength (185&254nm) ultraviolet lamp module, restrain bacteria’s increase and reduce TOC.

- MWCO 5000D ultrafiltration module, effectively eliminate endotoxin, and suitable for precise cell cultivating and IVF.

- (0.45+0.1)µm double layer PES terminal disinfection filter, assure that terminal pure water is absolutely axenic.

Smart-Q series deionized water system (Tap water inlet)

With injection molding process case, single stage RO system, 1 pump, portable TDS test pen and on-line resistivity monitor, Smart-Q series deionized water system is sub-economic choice of deionized water for general grade experiments.

With tap water inlet, its output ranges from 15 to 30 liters/hour. It can produce single stage RO water and deionized water. The single stage RO water’s ion rejection rate is more than 96%, and the deionized water’s resistivity is more than 15MΩ.cm, near to18.2MΩ.cm. It completely meets the requirements of general chemical or biological experiments for pure water.

Specifications

| Model | Smart-Q15 | Smart-Q15UT | Smart-Q30 | Smart-Q30UT |

| Output(25℃)* | 15 liters/hour | 30 liters/hour | ||

| Flow rate | Up to 2 liters/minute (with pressure tank) | |||

| Pure water outlet | 2: reverse osmosis water, deionized water | |||

| Deionized water quality | ||||

| Resistivity | 15-18.2MΩ.cm | |||

| Bacteria | N/A | <0.1cfu/ml | N/A | <0.1cfu/ml |

| Particle(>0.1μm) | N/A | <1/ml | N/A | <1/ml |

| RO water quality | ||||

| Ion rejection rate | 96%-99% (new RO membrane) | |||

| Organic rejection rate | >99%, when MW>200 Dalton | |||

| Particles and bacteria rejection rate | >99% | |||

| Feed water requirements | Tap water, temperature:5-45℃,pressure:1.0-4.0Kgf/cm2 | |||

| Dimension and weight | Length×Width×Height:410×220×420mm / Weight: about 18Kg | |||

| Electrical requirements | AC110-240V, 50/60Hz | |||

| Power | 72W | |||

| Standard configuration | Main body (Including 1 set of cartridge)+15 liters pressure tank+ TDS/conductivity test pen | |||

Remarks: The value will be influenced by temperature and feed water’s quality.

Smart-RO series reverse osmosis water system (Tap water inlet)

With injection molding process case, single stage RO system, 1 pump, and portable TDS test pen, Smart-RO series reverse osmosis water system is economic choice of RO water for general glassware washing.

With tap water inlet, its output ranges from 15 to 30 liters/hour. It can produce single stage RO water. The single stage RO water’s ion rejection rate is more than 96% (new RO membrane), organic rejection rate>99% (when mw>200 Dalton), particles and bacteria rejection rate>99%. It is suitable for glassware washing, feed of ultrapure water system, autoclave sterilizer, constant temperature and humidity chamber, salt spray test chamber, dampening machine and etc.

Specifications

| Model | Smart-RO15 | Smart-RO30 | ||

| Output(25℃)* | 15 liters/hour | 30 liters/hour | ||

| Flow rate | Up to 2 liters/minute (with pressure tank) | |||

| Pure water outlet | 1: reverse osmosis water | |||

| RO water quality | ||||

| Ion rejection rate | 96%-99% (new RO membrane) | |||

| Organic rejection rate | >99%, when MW>200 Dalton | |||

| Particles and bacteria rejection rate | >99% | |||

| Bacteria | <0.1cfu/ml (with optional 0.45+0.1μm PES terminal filter) | |||

| Particle(>0.1μm) | <1/ml (with optional 0.45+0.1μm PES terminal filter) | |||

| Feed water requirements | Tap water, temperature:5-45℃,pressure:1.0-4.0Kgf/cm2 | |||

| Dimension and weight | Length×Width×Height:410×220×420mm / Weight: about 16Kg | |||

| Electrical requirements | AC110-240V, 50/60Hz | |||

| Power | 48W | 72W | ||

| Standard configuration | Main body (Including 1 set of cartridge)+15 liters pressure tank+ TDS/conductivity test pen | |||

Remarks: The value will be influenced by temperature and feed water’s quality.

Smart-D series ultrapure water system (Distilled water inlet)

With injection molding process case, 1 pump, portable TDS test pen and on-line resistivity monitor, Smart-D series ultrapure water system is sub-economic choice of ultrapure water for high grade experiments.

With pure water or distilled water inlet, its output is up to 2 liters/minute. It can produce deionized water and ultrapure water. The deionized water’s resistivity is above 5MΩ.cm, and the ultrapure water’s resistivity absolutely reaches to 18.2MΩ.cm. It completely meets the highest grade I standard of ASTM, CAP, CLSI, EP and USP.

Specifications

| Model | Standard | Eliminating endotoxin | Low TOC | Synthesizing |

| Smart-D | Smart-DUF | Smart-DUV | Smart-DUVF | |

| Output | Up to 2 liters/minute (less output with UF cartridge) | |||

| Pure water outlet | 2: deionized water, ultrapure water | |||

| Ultrapure water quality | ||||

| Resistivity(25℃) | 18.2MΩ.cm | |||

| TOC* | <10ppb | <10ppb | <3ppb | <3ppb |

| Bacteria | <0.1cfu/ml | |||

| Particle(>0.1μm) | <1/ml | |||

| Endotoxin | N/A | <0.001Eu/ml | N/A | <0.001Eu/ml |

| RNases | N/A | <0.01ng/ml | N/A | <0.01ng/ml |

| DNases | N/A | <4pg/μl | N/A | <4pg/μl |

| Deionized water quality | ||||

| Resistivity(25℃) | >5MΩ.cm | |||

| Feed water requirements | RO water, distilled water, deionized water, 5-45℃,1atm* | |||

| Dimension and weight | Length×Width×Height:410×220×420mm / Weight: about 16Kg | |||

| Electrical requirements | AC110-240V, 50/60Hz | |||

| Power | 72W | |||

| Standard configuration | Main body (Including 1 set of cartridge)+ TDS/conductivity test pen | |||

Remarks: The value will be influenced by temperature and feed water’s quality.

Smart-S series ultrapure water system (Tap water inlet)

With injection molding process case, single stage RO system, 1 pump, portable TDS test pen and on-line resistivity monitor, Smart-S series ultrapure water system is sub-economic choice of ultrapure water for high grade experiments.

With tap water inlet, its output ranges from 15 to 30 liters/hour. It can produce single stage RO water and ultrapure water. The single stage RO water’s ion rejection rate is more than 96%, and the ultrapure water’s resistivity absolutely reaches 18.2MΩ.cm. It completely meets the highest grade I standard of ASTM, CAP, CLSI, EP and USP.

Specifications

| Model | Standard | Eliminating endotoxin | Low TOC | Synthesizing |

| Smart-S15 | Smart-S15UF | Smart-S15UV | Smart-S15UVF | |

| Smart-S30 | Smart-S30UF | Smart-S30UV | Smart-S30UVF | |

| Output(25℃)* | 15series-15 liters/hour, 30 series-30 liters/hour | |||

| Flow rate | Up to 2 liters/minute (with pressure tank) | |||

| Pure water outlet | 2: reverse osmosis water, ultrapure water | |||

| Ultrapure water quality | ||||

| Resistivity(25℃) | 18.2MΩ.cm | |||

| TOC* | <10ppb | <10ppb | <3ppb | <3ppb |

| Bacteria | <0.1cfu/ml | |||

| Particle(>0.1μm) | <1/ml | |||

| Endotoxin | N/A | <0.001Eu/ml | N/A | <0.001Eu/ml |

| RNases | N/A | <0.01ng/ml | N/A | <0.01ng/ml |

| DNases | N/A | <4pg/μl | N/A | <4pg/μl |

| RO water quality | ||||

| Ion rejection rate | 96%-99% (new RO membrane) | |||

| Organic rejection rate | >99%, when MW>200 Dalton | |||

| Particles and bacteria rejection rate | >99% | |||

| Feed water requirements | Tap water, temperature:5-45℃,pressure:1.0-4.0Kgf/cm2 | |||

| Dimension and weight | Length×Width×Height:410×220×420mm / Weight: about 18Kg | |||

| Electrical requirements | AC110-240V, 50/60Hz | |||

| Power | 72W | |||

| Standard configuration | Main body (Including 1 set of cartridge)+15 liters pressure tank+ TDS/conductivity test pen | |||