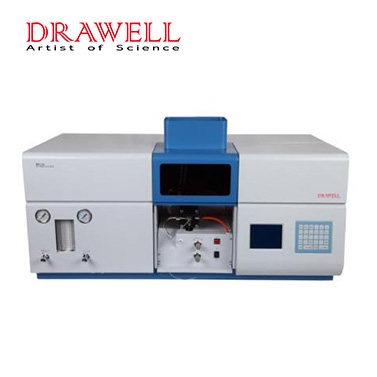

Single Beam DW-AA4530F Atomic Absorption Spectrophotometer (8 Lamp Stand)

The DW-AA4530F atomic absorption spectrophotometer is completely controlled by a PC, which can be flexibly equipped with flame, graphite furnace atomizer, and highly automated atomic absorption spectrophotometer. Unique optical-mechanical design, safe and convenient flame system, advanced graphite furnace temperature control technology, optional buckle background technology, and various convenient functions provided by the workstation, to meet your pursuit of automatic and accurate measurement results. With more than 500 data self-storage and power storage functions.

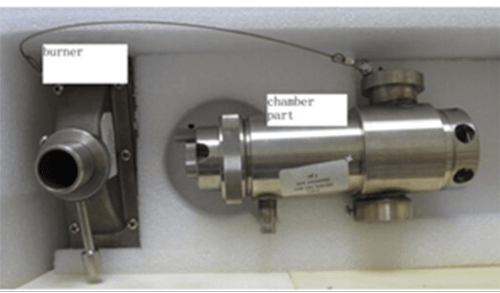

Optional Accessories:

- Autosampler

- Graphite Furnace

- Burner Head

- Glass atomizer

- Hydride Generator

- Chilled water unit

- Ventilating Hood ( 1.5 meters )

Features of DW-AA4530F Atomic Absorption Spectrophotometer

1.PC software control: can flexibly select the flame and graphite furnace atomizer (optional). All parameters of the instrument are set by computer software, and the program is automatically controlled.

2. Three working modes can be selected: absorbance (continuous integration signal, peak height/peak area integration signal), concentration straightness, and flame emission intensity. It has four signal modes: atomic absorption, background absorption, background deduction correction, and emission intensity.

3.1ntegrated floated optical platform design can obviously improve the optical system shock resistance and keep stable though use the optical signal for a long term.

4. Eight light stands can be changed automatically, with the functions of simultaneous preheating, automatic rotation switching, automatic ignition, and automatic optimization of the working conditions of hollow cathode lamps.

5. Position adjustment: The ideal height and front and rear position of the flame burner are automatically set.

6. Perfect safety interlock protection device: The system has an alarm safety protection function for incorrect connection of combustion head, gas leakage, air under pressure, abnormal flameout, etc.

7. Complete safety chains protection equipment: the function of warning and automatic safety protection towards the wrong burner, leakage of the gas, under voltage of air, and the abnormal flameout.

8. Deuterium lamp and self-absorption background regulation. It has the functions of automatic wavelength scanning, automatic gain, background correction, automatic energy balance, and automatic peak search according to the peak search method.

9. Data processing: super strong database, possesses more than 500 data self-storage and cut-off storage function, can store the analyzed result with the form of EXCEL and the testing method and the result can be randomly called.

10. Measuring method: flame absorption method and emission method.

11. Result printing: parameter printing, data result in printing, and diagram printing.

Specifications of the DW-AA4530F AAS

| Wavelength range | 190 – 900nm |

| Spectral bandwidth | 0.1, 0.2, 0.4, 1.0 and 2.0nm |

| Accuracy of the wavelength | ±0.15nm |

| Receptivity of the wavelength | ≤0.04nm |

| Base line stability | ≤0.002A/30min (Cu) |

| Characteristic viscosity | 0.02μg/ml/1% (Cu) |

| Checking limit | 0.004μg/ml (Cu) |

| Preciseness | 0.50% |

| Grating | 1800 lines/mm |

| Inflamer | All-metal titanium burner |

| Atomizer | Effective glass atomizer |

| Lamp stand | 8 |

|

|

|

Flame System

| Acetylene air burner | 100mm |

| Ignition dynamic baseline drift | ≤0.006A/30min |

| (Cu) Characteristic viscosity | ≤0.025μg/ml/1% |

| Related standard deviation of the accuracy | ≤0.5%(Cu, absorbance>0.8A) (detection limit Cu≤0.008μg/ml) |

| Safety system | Can automatically cut off the gas when the pressure is not enough, the power is off, flameout and unconformity of the burner. |

Graphite Furnace

| The highest temperature | 3000℃ |

| The largest temperature rising speed | ≥2000℃/S |

| Characteristic quantity | Cd≤0.5×10-12g Cu≤0.5×10-11g |

| Accuracy | Cu≤3% Cd≤3% |

| Size and weight | 550mm×450mm×300mm 65Kg |

| Safety system | Over-current protection Low air pressure alarm/protection Low cooling water flow alarm/protection |

| Power source and power | 220V±22V AC 7000W |

Standard Accessories

PC workstation

HP ink-jet printer

Oil-free Air compressor

Acetylene reducing valve

Cu Hollow cathode lamp

Air filter

Complete Automatic Controlling System

With the help of the software, the following can be easily achieved.

- Selection of the element lamp

- Up-down-front-rear adjustment of the lifter

- Adjustment of the optical energy

- Selection of the slit

- Determination of wavelength scanning and peak searching

- Selection of the atomizer

- The setting of the background deduction method

- Controlling the gas flow

- Automatic flaming and flaming out

- The setting of the graphite furnace testing method

Advanced Graphite Furnace Temperature Controlling Technology

The bringing in of PTD technology can effectively overcome the influence on the temperature rising process caused by the voltage fluctuation and the resistance change to make a more accurate controlling process. The combination of the 3ms/time fast sampling technique can make more accurate and reliable testing data

The fast heating capacity can improve the flexibility of the elements further

Use the ordinary power source of 220V without the need of dynamic power of 380V

The maximum procedure heating capacity setting of 20 levels can make a more convenient and easier test of different samples Three grades of adjustable gas flow can accustom to more application needs

Can timely alarm when the gas and water are stopped and insufficient gas and water, can avoid equipment damage and measuring error

Safe, Reliable, and Convenient Flame System

EPC can control the flow of Acetylene (C2H2) more accurately and it is a kind of system that also can operate easily

Efficient a Tomi zati on s ys tern enables a higher Sensitivity. The whole operating system has high security as the fire safety system can alarm whenever the electricity is cut off, abnormal flame occurs, a lack of pressure happens or the burner does not match well. And it will automatically turn off the gas, prohibiting tempering. Thus it keeps the operation people and equipment from harm and damage.

Multi-Functional Software Workstation

- Aworkstationthatissupported Windows XP/2000/NT

- The rich menu brings great convenience to the use of customer

- Convenient conversion between different menus makes the operation more easily

- Various analytical correction methods provide the users with more choices

- Basic default parameter settings enable even the beginners can do the normal operation

- Flexible storage, editing, and printing methods give the user the largest support

Standard Packing List

| Sr. | Description | Qty. |

| 1 | Polyethylene pipe φ12*8 | 3 |

| 2 | Nylon pipe φ6*1 | 20 |

| 3 | O-ring φ6*1.9 | 6 |

| 4 | O-ring φ10*2 | 10 |

| 5 | O-ring φ14*2 | 6 |

| 6 | O-ring φ17*2.65 | 3 |

| 7 | O-ring φ31*3.5 | 3 |

| 8 | Fuse 3A | 3 |

| 9 | Fuse 0.5A | 4 |

| 10 | Nut | 4 |

| 11 | Threaded sleeve | 8 |

| 12 | Bush | 8 |

| 13 | Sealed gasket | 8 |

| 14 | Light board | 1 |

| 15 | Connector of acetylene regulator | 1 |

| 16 | O-ring φ55*3.1 | 3 |

| 17 | Wrench 8*10 | 1 |

| 18 | Wrench 12*14 | 1 |

| 19 | Wrench 17*19 | 1 |

| 20 | Screwdriver (“+”) | 1 |

| 21 | Dongle | 1 |

| 22 | Igniter assembly | 1 |

| 23 | Cable | 1 |

| 24 | Power line | 1 |

| 25 | Cu lamp | 1 |

| 26 | Atomizer | 2 |

| 27 | Workstation software | 1 |

| 28 | USB2.0 to 232 serial cable | 1 |

| 29 | Air dryer and filter assembly | 1 |

| 30 | Holder of air dryer and filter assembly | 1 |

| 31 | Main instrument | 1 |

| 32 | Computer | 1 |

| 33 | Printer | 1 |

| 34 | Air compressor | 1 |

DW-AA4530F AAS Display