X-Ray Fluorescence Spectrometer (XRF)

What is X-Ray Fluorescence Spectrometer?

X-ray fluorescence (XRF) uses X-rays and fluorescence technology. When primary X-rays are irradiated on the sample to be tested, the secondary X-rays generated are called X-ray fluorescence. The composition and energy of the substance are analyzed by analyzing the wavelength and energy of the fluorescence.

XRF has the advantages of a simple spectrum, no damage to samples, simple operation, rapid determination, etc., and is widely used in geology, metallurgy, mining, non-ferrous metals, marine, biochemical, environmental, petrochemical, commodity inspection, electronics, public security, and archaeology, Refractory materials, and building materials industry, and other fields.

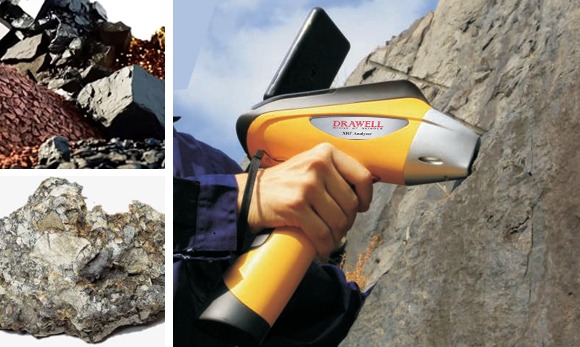

Handheld XRF

Handheld XRF analyzer using an integrated group of instrument components that are sealed in an ergonomically designed, lightweight body.

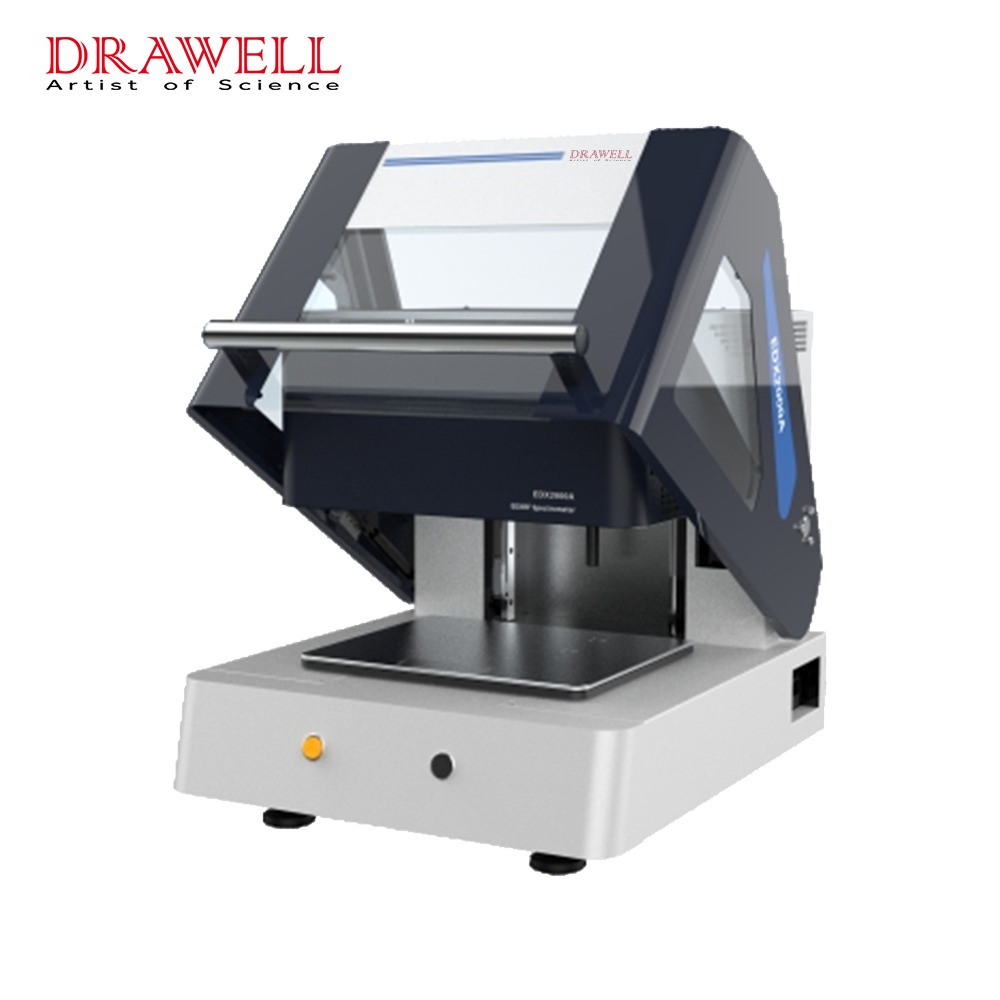

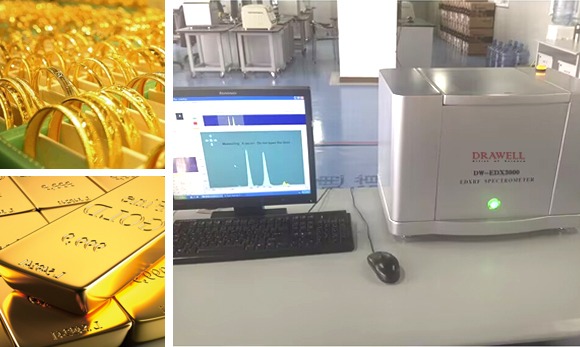

Desktop XRF

The high-performance desktop XRF is equipped with globally advanced analysis technology, an intelligent vacuum system, and developed electronic technology. Combined with a low-energy tube vacuum system and low background technology. It efficiently reduces testing interference and improves energy resolution of Mg, Al, Si P, and other light elements in geology and minerals, and accordingly an ideal choice for quality control in large and middle-scaled enterprises

Applications of X-Ray Fluorescence Spectrometer

XRF for Mineral

- Widely used in geological industry: ore detection, slag refining, archaeological research. (iron ore, copper, chromium, molybdenum, tungsten, tantalum ore, lead-zinc ore, nickel laterite ore, copper nickel sulphide etc.)

- Composition analysis of alloys.

- Gold in ore or alluvial gold detection.

- Other minerals detection.

Drawell XRF Recommends:

XRF for Alloy

- Nondestructive, rapid and accurate analysis of alloy elements and alloy grade identification on the site.

- Metal identification /scrap metal sorting.

- QA/QC management in metal production, processing, casting, etc.

- Identification of positive materials, oil refining and petrochemical industry.

- Thermal power plant, hydroelectric power station, nuclear power plant.

- Accurate element analysis of raw material and PMI identification.

Drawell XRF Recommends:

XRF for Precious Metal

- Nondestructive, rapid and accurate analysis of Precious Metals.

- Precious Metals Grade identification.

- Precious Metals elements and contents analyze.

- Content testing of precious metals Au, Pt, Ag in all kinds of ornaments.

- Used in pawn shops, jewelry industry, banking industry, jewelry testing centers, mining, precious metal recycling, precious metal material research laboratories, etc.

Drawell XRF Recommends:

XRF for RoHS

- RoHS detection and analysis.

- Detecting hazardous substances in electric and electronics industries, electroplating industries, various materials, plastics, wood, glass and others.

- Detection for electroplating industries.

Drawell XRF Recommends:

XRF for Soil

- Soil pollution survey and environmental assessment

- Soil pollution emergency treatment and remediation

- Rapid inspection and measurement of metal components in polluted water, waste water, the polluted ways, the polluted boundary.

- Real-time monitoring RCRA related metals and priority control polluted metals.

- Used to analyze for sand, sludge, solid waste, soil, mud, dust, powder, filter material, etc.

Drawell XRF Recommends:

XRF for Catalyst

- Raw material testing of catalyst products

- Identification of car catalyst products

- Quality control in the manufacture of catalyst products

- Recovery and evaluation of car catalyst converters

Drawell XRF Recommends:

XRF for Cement

- Building materials (cement, glass, ceramics)

- Metallurgy (steel, non-ferrous metals)

- Petroleum (trace elements S, Pb etc)

- Chemical engineering

- Geography and Mining

- Commodity and Quality Inspection

Drawell XRF Recommends:

Features of XRF Spectrometer

Handheld XRF

- Small, light, and easy to carry.

- High-speed processing chip, resulting in even faster analysis.

- High-performance X-ray Tube, super-high detection resolution.

- One-touch operation, easy to operate by non-technical users.

- Nondestructive testing (NDT).

- Drawell analysis software.

- Power saving can automatically switch to standby mode.

Desktop XRF

- High precision, fast testing speed, easy operation, etc.

- Bear several testing analysis modes, including alloy soil precious, and RoHS.

- Testing samples can be solids, liquids, and powders.

- Highly efficient super-thin window-ray light tube, which is specially developed for mineral testing, reaches the international advanced level.

- Automatic switch of collimator and filter according to different samples, eliminating the troublesome manual operation.

- Software protection: Automatic shut-down of software program when opening the cover during testing.

- Principle of Wavelength Dispersive Spectroscopy.

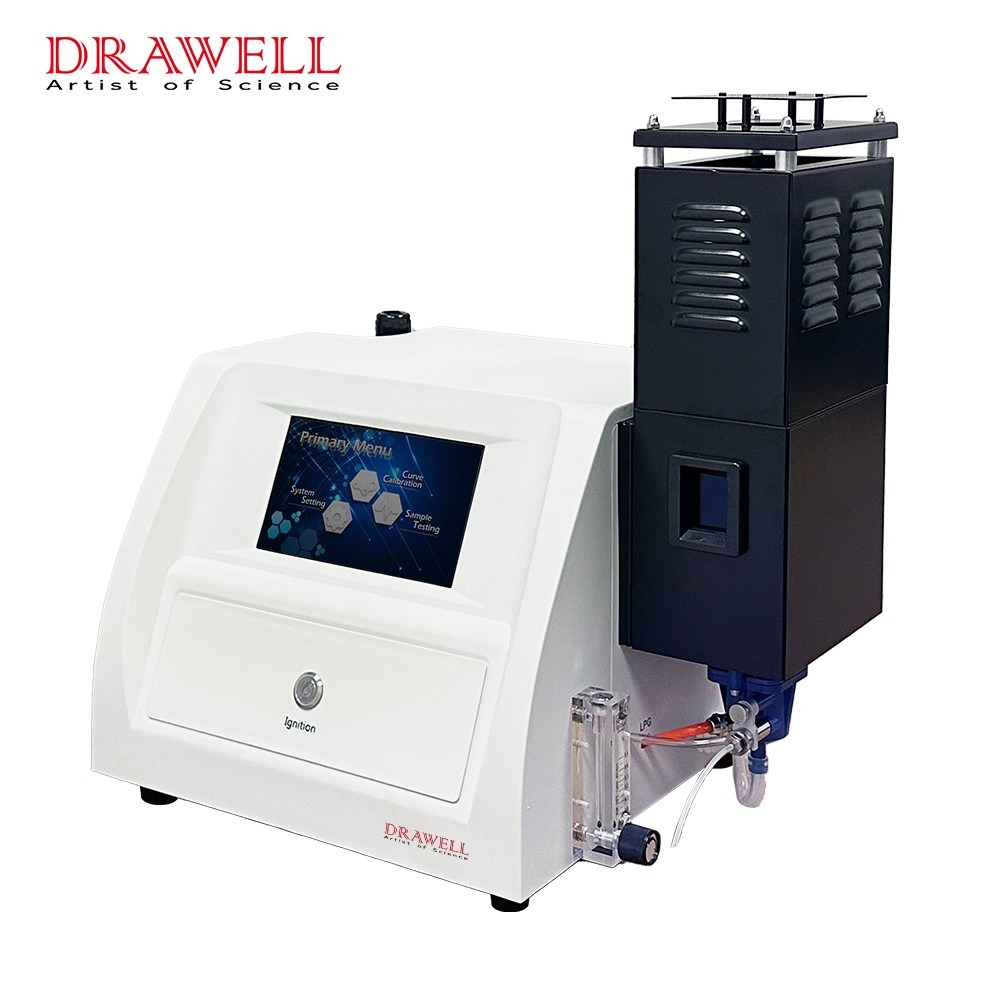

Different Applications of Spectrophotometer

| Application | Spectrophotometer Type | Picture | Model |

| Gold in Ore, Metallurgy. Geology, Mining, Petroleum. Cement, Soil, Medicine, etc. |

AAS |  |

DW-AA320N |

| Alloy, Mineral, Precious Metal, RoHS, Catalyst etc. | XRF |  |

DW-NP-5010 |

|

EDX3600H | ||

|

TrueX 900 | ||

|

EDX800 | ||

| MaterialsAnalysis, Geology, Petrochemicals, Biology, Cement, Soil, Cosmetics, Food, etc. |

ICP-AES |  |

ICP700T |

| Foundry, Steel, Metal Recovery, Smelting, MilitaryAerospace, etc. | Full Spectrum Direct Reading Spectrometer |  |

DW-TY9000 |

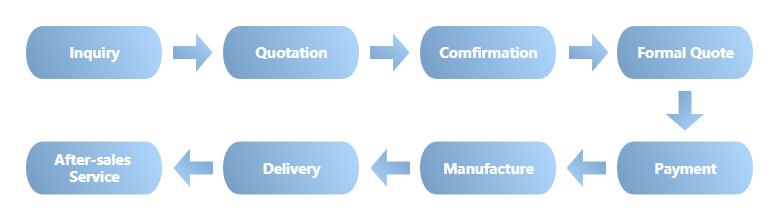

Why Choose Us for XRF?

“Multiple suppliers” have always been an issue in the procurement process. Drawell as a one-stop laboratory equipment and scientific instruments supplier, can perfectly solve this problem. In addition to manufacturing our own equipment, we also represent other laboratory equipment. Our product lines are rich and diverse at competitive prices. Provide one-stop service to customers.

User Training – Training by Drawell skilled engineers about installation, debug tests, technical services, etc. It can happen in our factory in China, or at the site in the customers’ country. Cost depends on where and when the training happens.

To discuss the problem and get it resolved, online chats, real-time video calls, and remote guidance. For the after-sales stage, our online technical guidance is free and ready forever.

1 year free official warranty, including repairing quality-damaged parts, and offering replacements of selected parts (shipping cost is extra). 5% of the product price is charged for extending the warranty before the end of the official warranty.

Customer Feedbacks: