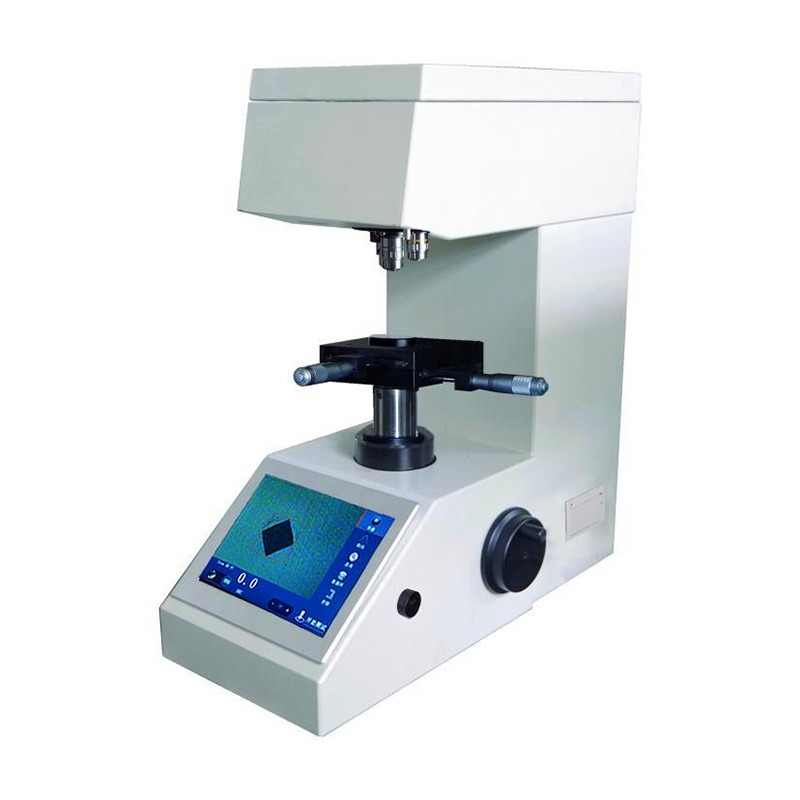

MHVS-5/10/30/50V Visual Vickers Hardness Tester

Unlike the traditional Vickers hardness tester, this Visual Vickers hardness tester cancels the use of traditional measuring eyepiece, projectes the Vickers indentation image to the operating screen, and can measure the indentation diagonal in the screen. The test process is faster and more intelligent to meet your requirement of high efficiency, convenience and precision hardness testing.

Characteristic of MHVS-5/10/30/50V Vickers Hardness Tester

“Aolong Controlling System” Characteristics:

- High Precision Step Control Electric Loading Technology

- High accuracy of test force

- The loading speed of main test force is fast and the efficiency is high.

- High Precision Sensor

- The Unique Value Curve

- Loading and unloading speed is faster and more accurate

- The remote control can be realized and the operation is simple.

- Extremely Fast Loading Speed: Loading Time of Test Force 2-10 seconds

- Intelligent control of the whole process. Sectional force application, smooth speed change, high precision and high speed step control, etc.

Visual system characteristics

- Objectivity: The visual system has objectivity, and the results of analysis are not affected by subjectivity.

- High gray resolution: human eyes generally have 64 gray scales, and machine vision can reach 256 gray scales.

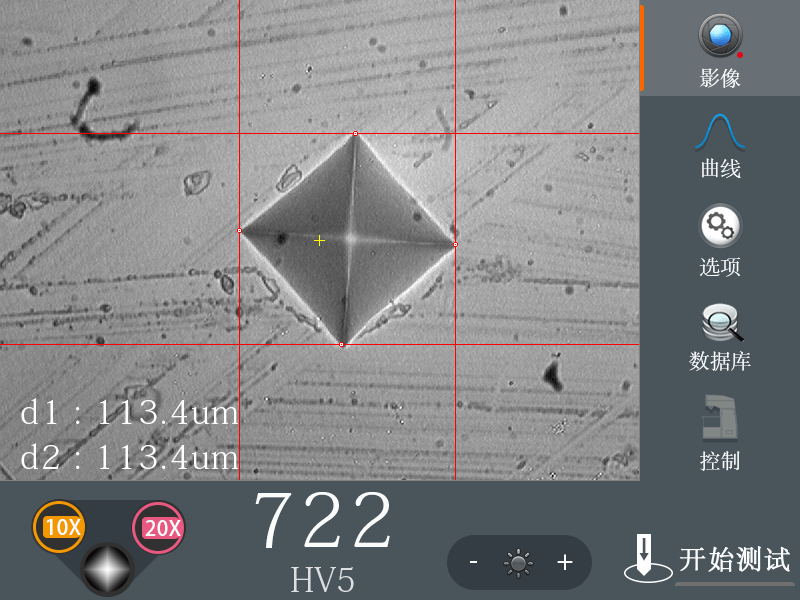

- Embedded image technology replaces traditional measuring eyepiece, using camera + display mode, indentation image, direct display screen.

- Type of Visual Chip: Industrial-grade Special High Definition Camera

- Contrast, brightness, white balance and other adjustments are available.

- Visual analysis model simplifies manual operation process, reduces operator fatigue, and makes measurement data more intuitive and convenient.

- Optimizing each link greatly improves the overall performance of the hardness tester and saves 50% of the time compared with the traditional hardness tester.

Advantages of vision system relative to eyepiece measurement

- There is no visual error when measuring directly on the surface that needs to be measured. The hardness tester of traditional structure is measured by eyepiece. The calibration line and indentation are not on one plane. Under different angles of view, the calibration position and indentation position will produce visual difference, which will lead to different angles of view and different results of personnel measurement.

- High measurement accuracy: there is no problem of mechanical eyepiece error. The calibration resolution of mechanical eyepiece helical microstructures is about 10 m, and there is mechanical backlash, so it is necessary to define the measurement method strictly. Pixel spacing of image sensor in vision system is 7.5 m, which has high precision and good measurement consistency.

- It can provide two-dimensional simultaneous measurements of various measurement modes, simplify the measurement process and improve the measurement speed.

- With rectangular tangent measurement method

- No visual fatigue, reduce the measurement of labor intensity. The vision system adopts 65K true color TFT LCD screen, which is comfortable to observe and not fatigued, and can be measured by many people at the same time.

Technical Parameters of MHVS-5/10/30/50V Vickers Hardness Tester

| Model | MHVS-5V | MHVS-10V | MHVS-30V | MHVS-50V |

| Test force(kgf) | 0.2、0.3、0.5、1、2、3、5 | 0.3、0.5、1、2、3、5、10 | 0.5、1、2、3、5、10、20、30 | 1、2、3、5、10、20、30、50 |

| Loading method | Automatic loading and uploading | |||

| Test force switching | Automatic | |||

| Language selection | Chinese-English | |||

| Dwell time | 5-60s | |||

| Indenter and objective lens switching | Automatic | |||

| Testable parameter | HV\HK | |||

| Objective lens | 10X、20X | |||

| Maximum measuring length | 400µm | |||

| Minimum Resolution | 0.1µm | |||

| Maximum height of sample | 160mm | |||

| Distance from the center of the indenter to the body | 135mm | |||

| Scale conversion | HV、HK、HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRK、HR15N、HR30N、HR45N、 HR15T、HR30T、HR45T、HBW | |||

| Touch screen operation panel | Image, Force Curve, Options, Database, Control, Loading Start, Lighting Adjustment, Object Lens Switching | |||

| Value Display | D1, D2 value, HV, HK indication, hardness value, conversion value, shelf life, test times | |||

| Light source | 5V/3W white light LED | |||

| Communication interface | RS 232 | |||

| Executive standard | JJG151,GB/T 4340, ISO/DIN6507,ASTM E-384 | |||

| Photographic device | Built-in HD camera | |||

| Power supply | AC90-240,50-60Hz | |||

| Shape size | 473*190*637mm | |||

| Machine net weight | About 70kg | |||

Sample requirements

Although Vickers hardness can be used to measure both soft and hard materials, it also has its own requirements for specimens. Only by choosing the appropriate sample can the error caused by this be avoided and the accurate Vickers hardness value be obtained.

Sample appearance requirements

The surface of Vickers hardness specimen should be smooth and smooth, no oxide scale and impurities, no oil stain. Generally speaking, the surface roughness parameter Ra of Vickers hardness specimen is not more than 0.40μm, that of small load Vickers hardness specimen is not more than 0.20μm, and that of micro Vickers hardness specimen is not more than 0.10μm. (Micron is the unit of surface roughness parameter Ra.)

Requirements for sample preparation

During the preparation of Vickers hardness specimen, the influence of superheat or cold hardening on surface hardness should be minimized.

In addition, for specimens with small cross-section or irregular shape, such as spherical or conical, it is necessary to mosaic the specimens or use special platforms.

Host Standard Configuration of MHVS-5/10/30/50V Vickers Hardness Tester

| Name | Quantity | Name | Quantity |

| XY test-bed | 1 | Slice clamping table | 1 |

| Flat-mouthed clamping table | 1 | Filament clamping table | 1 |

| screwdriver | 2 | Horizontal adjustment screw | 4 |

| 10X Micrometer eyepiece | 1 | Vickers hardness block | 2 |

| Level | 1 | Spare fuse | 2 |

| Manual book | 1 | Product Qualification Certificate | 1 |