Determining the melting point of substances is a fundamental task in chemistry and material science. This process not only helps in identifying the purity of a sample but also provides critical information about its physical properties. Melting point apparatuses are specialized instruments designed to measure the temperature at which a substance transitions from a solid to a liquid state. With various types available on the market, selecting the right apparatus for your needs can be a challenging decision. This article explores the different types of melting point apparatuses based on their operation mode, level of automation, and technology used, and offers guidance on choosing the most suitable equipment for your laboratory.

Types of Melting Point Apparatus

Based on Operation Mode

Manual Melting Point Apparatus:

- Capillary Method: This traditional method involves filling a thin capillary tube with the sample and observing the melting point through a microscope or optical viewfinder. The user manually adjusts the heating rate and records the temperature at which the sample melts. This method is simple and cost-effective but requires careful observation and manual intervention.

- Visual Observation: Some manual systems use direct visual observation of the sample as it melts. The operator watches the sample through a microscope or magnifying lens and notes the melting point. This approach is straightforward but less precise compared to automated methods.

Automatic Melting Point Apparatus:

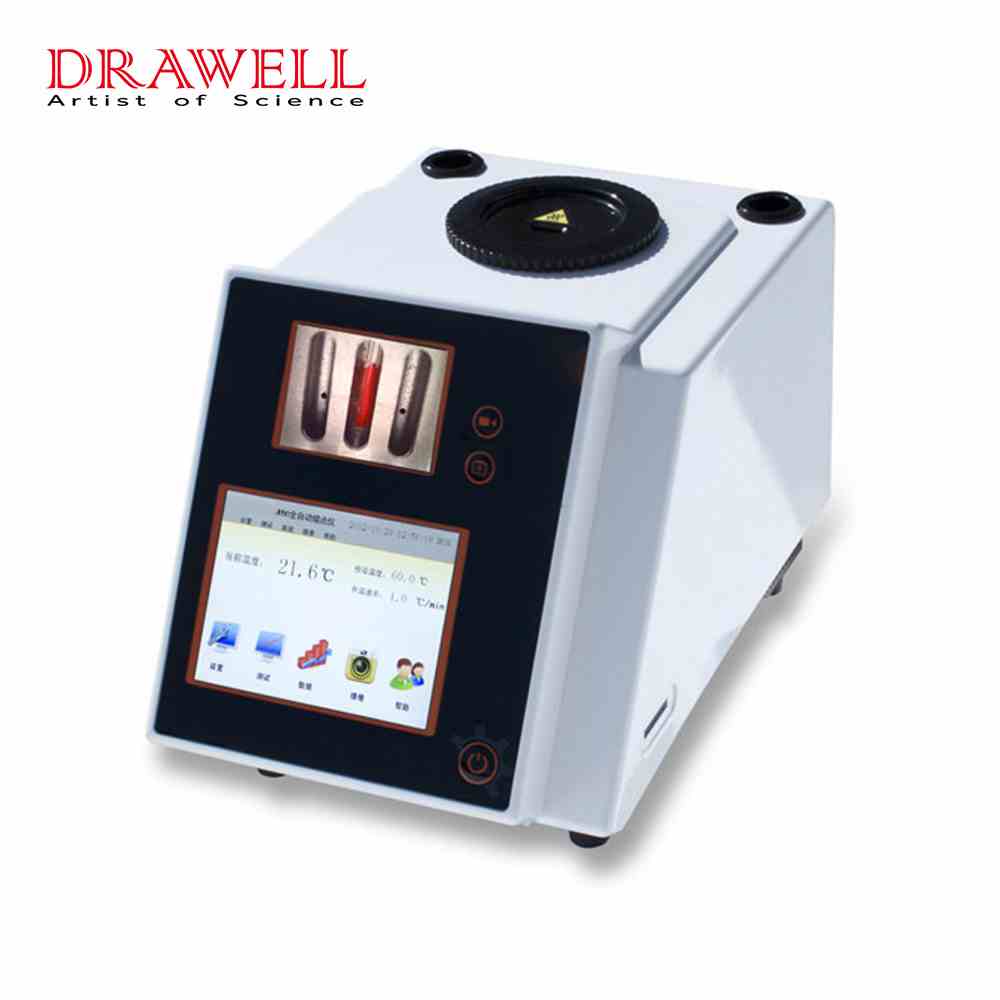

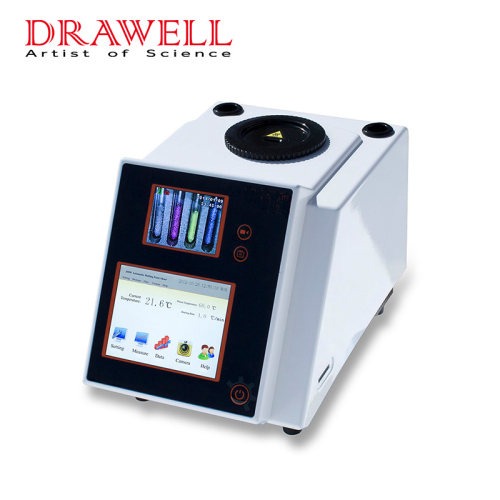

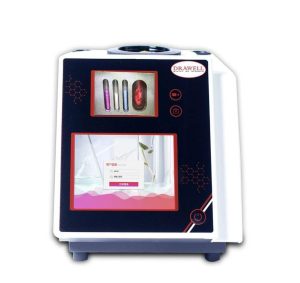

- Digital Readout Systems: These systems incorporate digital sensors to automatically detect and record the melting point. They feature built-in heating elements and temperature controllers, which provide more accurate and consistent measurements. The digital display allows for easy reading of results and reduces the need for manual observation.

- Thermal Imaging Systems: Advanced systems use thermal cameras to monitor the sample’s melting process. These systems offer high precision and can capture detailed thermal data, making them ideal for complex samples and research applications.

Based on Technology Used

Optical Methods

- Microscope-Based Melting Point Apparatus: Utilizes a microscope or optical viewfinder for manual monitoring of the melting process.

- Digital Melting Point Apparatus: Modern systems may use digital cameras to capture images of the melting process, which can be analyzed to determine the melting point.

Thermometric Methods

- Resistance Thermometers: Measure temperature based on changes in electrical resistance. These are commonly used in manual and semi-automatic systems.

- Thermocouples: Measure temperature by detecting the voltage generated at the junction of two different metals. They provide precise temperature readings and are used in various automated systems.

Different Thermocouples

Infrared Thermometry

Uses infrared sensors to measure the temperature of the sample without direct contact. This technology is useful for high-precision measurements and is often found in advanced systems.

Laser Technology

Employs laser scanning to measure the temperature of the sample with high accuracy. This method is suitable for research applications requiring precise temperature data.

Based on Level of Automation

From all the types, melting point apparatus can be mainly categorized based on level of automation. Here are the detailed comparison:

| Level of Automation | Manual Systems | Semi-Automatic Systems | Fully Automatic Systems |

| Description | Requires full manual operation: setting the heating rate, observing the melting process, and recording the melting point. | Offers partial automation, such as programmable heating rates, but still requires manual sample loading and observation. | Fully automates the entire process, including heating, detection, and recording of the melting point, often allowing multiple samples to be tested simultaneously. |

| User Intervention | High – users must manually observe and adjust the process. | Moderate – automation of heating but still needs user monitoring and input for some steps. | Low – minimal user involvement required once the sample is loaded. |

| Accuracy and Precision | Lower precision due to manual control and observation variability. | Moderate precision with automated heating but still reliant on user observation for final results. | High precision with automated detection, ensuring consistency across tests. |

| Ease of Use | Simple but labor-intensive; requires constant attention. | Easier than manual systems, thanks to automation of key functions, but still involves user interaction. | Very user-friendly; automated controls and processes significantly reduce workload. |

| Sample Throughput | Low – typically handles one sample at a time. | Moderate – can handle a few samples in sequence but still requires manual switching. | High – can process multiple samples at once, ideal for high-throughput environments. |

| Cost | Low – the most affordable option, best for simple applications and tight budgets. | Moderate – priced higher due to added automation features. | High – premium pricing for full automation, advanced features, and multiple sample capacity. |

| Best Suited For | Educational labs, small-scale operations, and basic research where budget is a concern and precision isn’t critical. | Labs needing improved accuracy and efficiency but still operating on moderate budgets. | Industrial labs, quality control environments, and research facilities that require high accuracy, efficiency, and the ability to process multiple samples quickly. |

Choosing the Right Melting Point Apparatus

Selecting the appropriate melting point apparatus depends on several factors, including:

- Sample type: The nature of the sample (e.g., solid, liquid, crystalline) will influence the suitable apparatus.

- Accuracy requirements: The desired level of precision in the melting point measurement will determine the necessary apparatus.

- Throughput: The number of samples to be tested per day will impact the choice of manual or automated equipment.

- Budget: The available budget will constrain the selection of options.

Recommended Products for Different Lab Applications:

| Application | Recommended Melting Point Apparatus | Reasons |

| Educational and Teaching Labs | Manual or Semi-Automatic Systems | Manual systems are affordable and straightforward, making them ideal for students learning basic techniques. Semi-automatic systems add convenience without increasing complexity. |

| Basic Research Labs | Semi-Automatic Systems with Digital Readouts | Provides enhanced accuracy and control over the heating process, ensuring reliable results for research purposes without the cost of full automation. |

| Industrial Quality Control | Fully Automatic Systems | High throughput and precision are critical in quality control environments. Fully automatic systems allow for simultaneous sample testing with minimal operator intervention. |

| Pharmaceutical and Chemical Labs | Fully Automatic Systems with Infrared or Laser Technology | For precise melting point determination of complex compounds, advanced systems using infrared or laser technology provide highly accurate and reproducible results. |

| High-Volume Testing Labs | Multi-Sample Fully Automatic Systems | When multiple samples need to be tested quickly and efficiently, fully automatic systems with multi-sample holders are the best choice. |

When choosing a melting point apparatus, consider the specific needs of your laboratory. Educational labs can opt for cost-effective manual systems, while research and industrial labs may benefit from the precision and convenience of semi-automatic or fully automatic systems. By carefully weighing factors like accuracy, automation, sample throughput, and budget, you can select the melting point apparatus that best suits your application, ensuring efficient and accurate melting point determinations.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.