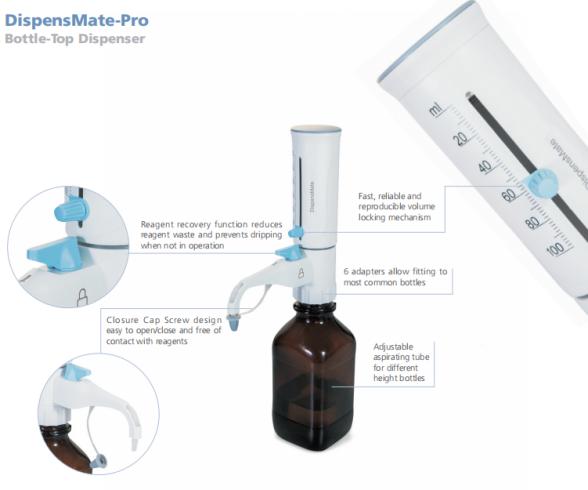

In laboratories, precision in liquid handling is essential. Among the tools that support this level of accuracy, bottle-top dispensersplay a critical role. The bottle-top dispensers come in two primary types: manual and electronic. While both fulfill the core purpose of delivering reliable volume measurements, they differ significantly in functionality, ease of use, and suitability for specific applications. This article explores the differences between manual and electronic bottle-top dispensers, helping you make an informed choice based on your workflow and needs.

Understanding the Functions of Bottle-top Dispensers in Laboratories

Bottle-top dispensers play a vital role in laboratory workflows by enabling the safe, accurate, and efficient dispensing of liquid reagents directly from storage bottles. They minimize the risk of contamination, reduce manual handling errors, and ensure consistent volume delivery for routine tasks such as titrations, solution preparation, and sample dilution. Their precision and ease of use make them indispensable tools in analytical, chemical, and biological laboratories.

Understanding Manual Bottle-top Dispensers

Manual bottle-top dispensers are a fundamental tool in laboratory liquid handling. They are designed to be mounted directly onto reagent bottles, allowing for safe, convenient, and accurate dispensing of liquids without the need to pour. Operated entirely by hand, these dispensers use a piston-driven mechanism where the user manually lifts and depresses a plunger to draw and deliver a specific volume of liquid.

How They Work

At the core of a manual bottle-top dispenser is a precision piston-cylinder system. When the plunger is pulled up, the piston retracts, drawing liquid into the chamber from the attached bottle. Pressing the plunger then forces the liquid out through a spout, often equipped with an anti-drip valve for controlled delivery. Volume settings are adjusted by a rotating dial or volume knob, allowing for repeatable measurements.

Common Applications

Manual dispensers are widely used across chemical, biological, and analytical laboratories for routine tasks such as:

- Dispensing solvents or acids

- Transferring reagents for titrations

- Filling tubes or vials with set volumes

- Sample preparation

Their reliability and straightforward operation make them especially popular in educational settings and general-purpose labs.

Advantages

- Simplicity and Ease of Use: No need for external power or electronics.

- Durability: Often built with chemical-resistant materials like PTFE or borosilicate glass.

- Cost-Effective: Ideal for labs with limited budgets or occasional liquid dispensing needs.

- Portability: Can be used anywhere without power constraints, including in field applications.

Limitations

Despite their benefits, manual dispensers can be labor-intensive during repetitive or high-volume tasks. Operator fatigue and inconsistencies in manual handling may affect reproducibility, especially when absolute precision is required.

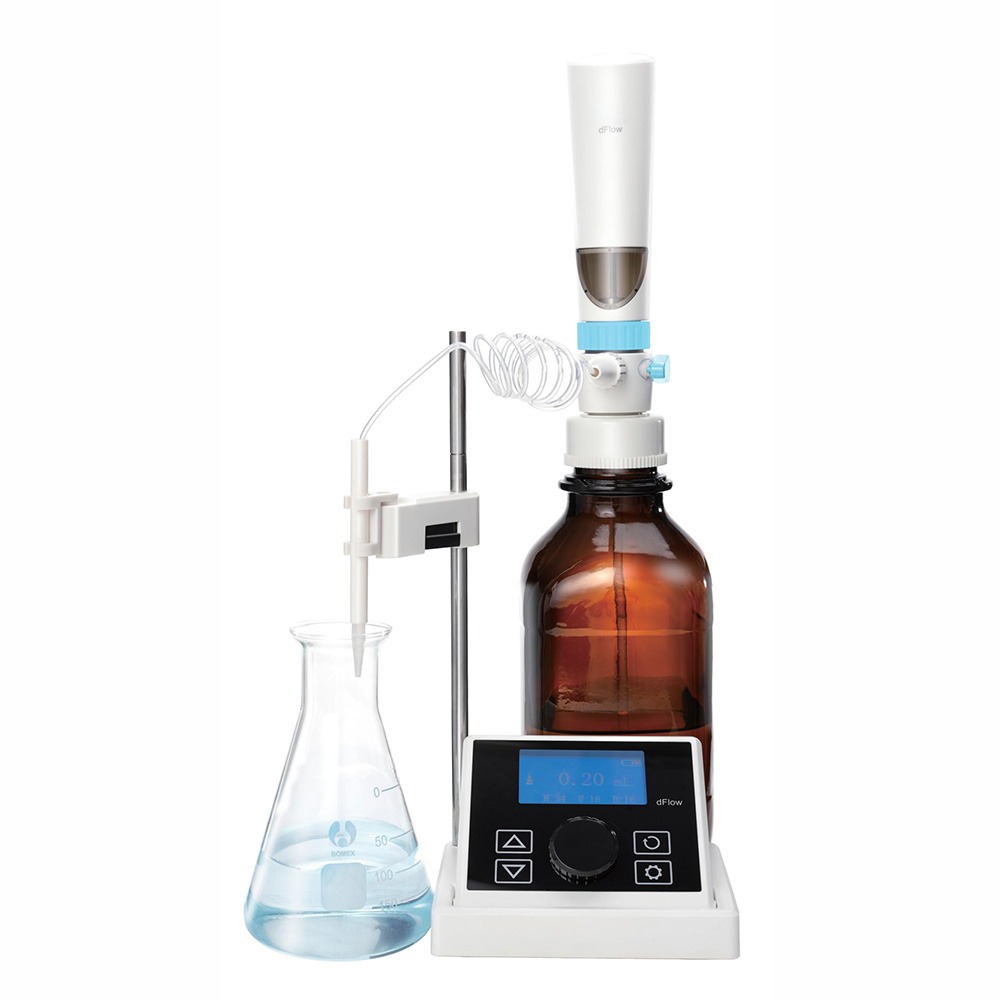

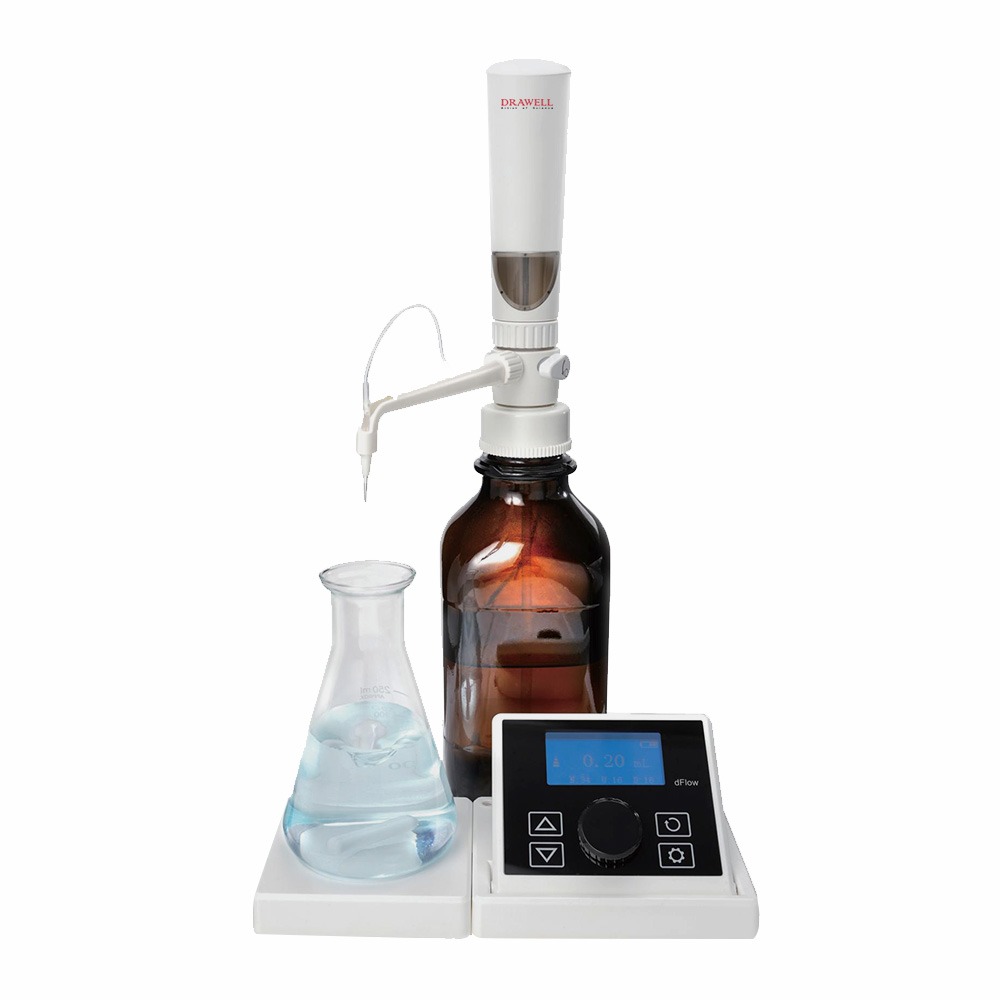

Understanding Electronic Bottle-top Dispensers

Electronic bottle-top dispensers represent a modern evolution in laboratory liquid handling, designed to improve accuracy, repeatability, and user comfort in high-throughput and precision-demanding environments. Unlike manual dispensers, which rely on mechanical force, electronic models operate using motorized systems controlled via buttons or touch panels.

How They Work

Electronic dispensers are equipped with a digital interface and a motor-driven piston mechanism. Users can program specific volumes, dispensing modes (e.g., single, multi-dispense, or sequential), and even set custom protocols depending on the model. Once programmed, the dispenser delivers the selected amount of liquid with consistent speed and force, minimizing human error and variation.

Key Features and Capabilities

Most electronic bottle-top dispensers come with digital displays, volume memory functions, and sometimes connectivity options for data logging or integration with laboratory information systems. Advanced models can store multiple user-defined methods, improving workflow efficiency. Safety features such as electronic locking, overfill protection, and auto-calibration help ensure both user safety and data reliability.

Ideal Applications

Electronic bottle-top dispensers are particularly useful in laboratories that require:

- High-precision dosing

- Repetitive or long series of dispensing tasks

- Reduced operator fatigue

- Documentation and traceability of dispensing actions

Fields such as pharmaceuticals, clinical diagnostics, analytical chemistry, and quality control testing benefit greatly from the automation and consistency provided by electronic dispensers.

Advantages

- Precision and Reproducibility: Enhanced control of volume and speed

- Efficiency: Fast and consistent liquid handling with programmable features

- User Comfort: Reduced hand strain during extended use

- Data Management: Optional tracking and memory for traceability

Limitations

While electronic dispensers offer superior functionality, they do require a higher initial investment and some level of training. Regular calibration and proper maintenance of electronic components are also important to ensure continued performance.

Comparing Manual vs. Electronic Bottle-top Dispensers

| Feature | Manual Bottle-Top Dispenser | Electronic Bottle-Top Dispenser |

| Operation Method | Manual plunger or piston | Motorized, button-controlled |

| Power Requirement | None | Battery or external power required |

| Ease of Use | Simple, user-dependent | High, especially for repetitive tasks |

| Precision and Accuracy | Good, varies with user consistency | Excellent, digitally controlled |

| Volume Setting | Manual dial or knob | Digital input with programmable functions |

| Throughput Suitability | Best for low to moderate volume tasks | Ideal for high-throughput, repetitive work |

| Fatigue Factor | Higher due to repeated manual action | Lower—minimal physical effort needed |

| Cost | Generally more affordable | Higher initial investment |

| Maintenance | Low; fewer mechanical parts | Requires care with electronic components |

| Application Suitability | Routine lab use, education, fieldwork | Research labs, QC labs, regulated industries |

| Data Management | Not available | Often includes memory, tracking, or connectivity options |

Choosing Between Manual vs. Electronic Bottle-top Dispensers

Selecting the right bottle-top dispenser for your laboratory depends on a variety of factors, including the nature of your work, the volume of liquid handling, accuracy requirements, available resources, etc.

- Consider the Nature of Your Work

Manual dispensers are well-suited for laboratories where liquid dispensing is occasional, low-volume, and does not require extreme precision. They offer reliability with minimal maintenance and no reliance on power sources, making them ideal for fieldwork, teaching labs, and basic chemical handling tasks.

Electronic dispensers, on the other hand, are designed for environments that demand consistent accuracy, speed, and efficiency, particularly in high-throughput settings. With digital volume control and programmable functions, they minimize user fatigue and reduce variability between doses. This makes them the preferred choice in pharmaceutical labs, analytical testing, and industrial applications where compliance and data traceability are crucial.

- Weighing Cost vs. Performance

While manual dispensers are generally more affordable upfront, electronic models offer long-term value for laboratories that require repetitive or complex dispensing. The higher cost of electronic dispensers is offset by their labor-saving benefits and enhanced accuracy, which can reduce errors and reagent waste over time.

- Maintenance and Calibration

Both types require regular maintenance to ensure long-term accuracy and performance. Manual dispensers typically need minimal servicing and are easier to clean. Electronic dispensers, due to their internal components and electronics, require more careful handling, software updates, and sometimes professional calibration services.

Summary

- For basic, flexible, and budget-friendly use, manual bottle-top dispensers are a dependable option.

- For tasks that demand precision, consistency, and efficiency, investing in an electronic bottle-top dispenser can significantly improve productivity and data integrity.

Final Thoughts

Whether to choose a manual or electronic bottle-top dispenser depends on your laboratory’s specific needs. By evaluating the demands of your workflow, volume requirements, budget, etc, you can select a bottle-top dispenser that enhances both productivity and accuracy in liquid handling processes for your Laboratories.

Related Products Recommendation

Get Quote Here!

Latest Posts

What Next?

For more information, or to arrange an equipment demonstration, please visit our dedicated Product Homepage or contact one of our Product Managers.