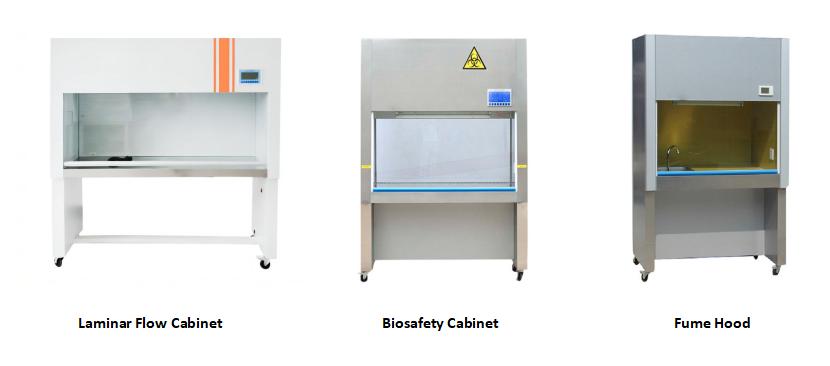

In the realm of laboratory safety and efficiency, selecting the appropriate equipment is paramount. Laminar flow hood and biosafety cabinet and fume hood are three critical pieces of equipment used in various laboratory settings. Each serves distinct purposes and offers unique features, making the selection process complex. Understanding their functions, comparative analysis, and key considerations for selection is essential for maintaining safety standards and optimizing laboratory workflows.

Overview of Laminar Flow Hoods, Biosafety Cabinets, and Fume Hoods

Laminar Flow Hood

Laminar flow hoods are designed to provide a controlled, clean environment by directing a unidirectional flow of filtered air over the work surface. This airflow helps to minimize airborne contamination and is particularly useful in applications requiring a sterile environment, such as tissue culture, microbiology, and pharmaceutical compounding. Laminar flow hoods come in two primary types: horizontal flow and vertical flow.

- Horizontal Flow Hoods: Air flows from the back of the hood to the front, creating a barrier-free workspace suitable for applications where sterility is critical.

- Vertical Flow Hoods: Air flows from the top of the hood downward, providing protection for the work surface and preventing contamination from above.

Biosafety Cabinet

Biosafety cabinets, also known as biological safety cabinets or BSCs, are specialized containment devices designed to protect laboratory personnel, the environment, and the samples being worked on from exposure to potentially hazardous agents. They are classified into three main types (Class I, II, and III) based on the level of protection they offer against biological or chemical hazards. Biosafety cabinets provide both personnel and environmental protection through high-efficiency particulate air (HEPA) filtration systems and airflow patterns that prevent the escape of harmful substances.

Fume Hood

Fume hoods are engineered to capture, contain, and exhaust hazardous fumes, vapors, or dust generated during laboratory procedures. They are essential for maintaining a safe working environment when handling volatile chemicals or substances that produce harmful airborne particles. Fume hoods are typically equipped with a powerful ventilation system that draws air away from the user and into the hood, where it is then safely expelled outside the laboratory or filtered before recirculation. The most basic distinction between fume hoods is whether they are ducted or ductless.

- Ducted Fume Hoods: These are the most common type of fume hoods. Ducted fume hoods are connected to an exhaust system that removes contaminated air and releases it safely outside the building. They provide efficient containment of fumes and offer a high level of protection for users.

- Ductless Fume Hoods: Also known as recirculating or filtered fume hoods, these hoods filter the air using various types of filters (e.g., HEPA filters, activated carbon filters) before recirculating it back into the laboratory. Ductless fume hoods are suitable for applications where ductwork is not feasible or where there are concerns about energy consumption or environmental impact.

Comparative Analysis of Laminar Flow Hoods, Biosafety Cabinets, and Fume Hoods

Laminar Flow Hoods, Biosafety Cabinets, and Fume Hoods are essential pieces of equipment used in laboratory and industrial settings to ensure the safety of personnel, protection of the environment, and the integrity of experiments or processes involving hazardous materials. While all three types of hoods serve the purpose of controlling contaminants, they have distinct designs, functionalities, and applications. Here’s a detailed comparative analysis of each:

| Aspect | Laminar Flow Hoods | Biosafety Cabinets (BSCs) | Fume Hoods |

| Design | Unidirectional, filtered airflow | Enclosed, ventilated workspace | Ventilated enclosure with an open front |

| Functionality | Provides sterile work area | Handles hazardous biological agents | Captures and removes chemical fumes |

| Protection | Protects product from contamination | Provides operator and environmental safety | Protects operators from chemical exposure |

| Applications | Cell culture, sample prep, etc. | Microbiology, clinical labs, research | Chemistry labs, industrial settings |

| Suitable Materials | Non-hazardous, low-risk biologicals | Hazardous biological agents | Hazardous chemicals, vapors, gases |

| Limitations | Not suitable for hazardous materials | Not suitable for chemicals or radioactive | Not suitable for biological agents |

| Maintenance Requirements | Minimal | Requires regular maintenance and certification | Requires regular maintenance and airflow monitoring |

| Industry Use | Pharmaceuticals, microbiology, electronics | Microbiology, clinical labs, research | Chemistry labs, pharmaceuticals, industrial |

In summary, while Laminar Flow Hoods, Biosafety Cabinets, and Fume Hoods serve distinct purposes and offer different levels of protection, they are all critical components of laboratory safety and containment strategies. This comparative analysis highlights the key differences and similarities between Laminar Flow Hoods, Biosafety Cabinets, and Fume Hoods. The choice of hood depends on the specific requirements of the application.

Key Considerations for Selecting Lab Equipment

When choosing between laminar flow hoods, biosafety cabinets, and fume hoods, laboratories must consider the following:

- Safety Requirements: Assess the level of containment needed to ensure the safety of laboratory personnel and prevent contamination of experiments.

- Workspace and Application: Determine the size of the workspace and the specific procedures being performed to select equipment that meets the laboratory’s requirements.

- Regulatory Compliance: Ensure that the chosen equipment complies with relevant regulatory standards and guidelines, such as those set forth by organizations like the Centers for Disease Control and Prevention (CDC) and Occupational Safety and Health Administration (OSHA).

- Budget Constraints: Consider the initial purchase cost, as well as ongoing maintenance and operational expenses, to make an informed decision that aligns with the laboratory’s budgetary constraints.

Conclusion

Laminar flow hoods, biosafety cabinets, and fume hoods are indispensable tools in laboratory settings, each serving distinct purposes and offering unique benefits. Understanding the functions, comparative analysis, and key considerations for selection is crucial for choosing the right equipment to ensure safety, efficiency, and compliance with regulatory standards. By carefully evaluating the specific needs of the laboratory application and considering factors such as safety requirements, application specificity, space constraints, and budgetary considerations, laboratory managers and researchers can make informed decisions when selecting lab equipment, ultimately enhancing laboratory workflows and safeguarding personnel, samples, and the environment. If you are looking for a lab equipment supplier, please feel free to contact Drawell.