Laminar Flow Cabinet

Laminar flow cabinets supplied by Drawell, provide a clean and controlled working environment by filtering air through a HEPA filter and delivering it in a unidirectional stream. These cabinets are widely used in industries requiring contamination control, such as pharmaceuticals, biotechnology, electronics, and research laboratories. They offer a range of features, including adjustable airflow speed, UV sterilization, and stainless steel construction, to ensure optimal performance and cleanliness.

Features of Laminar Flow Cabinet

- Using a remote to control the wind speed (two-stage wind speeds).

- Equipped with HEPA filter. With primary filter for preliminary filtration, which can effectively extend the life span of HEPA filter.

- Adopt Arbitrary positioning sliding door system.

- The shell is made of a colored steel plate, and the working table is SUS304 brushed stainless steel, which is corrosion-resistant and easy to clean.

- Lighting and sterilization system safety interlock.

- Digital explicit liquid crystal control panel. Three stages of wind speed(fast, medium, and slow). Except for SW-CJ-1D and SW-CJ-1G which only have two stages of wind speed.

- Vertical quasi-closed table, air curtain stroke of downdraft in the operation room, which can effectively prevent external gas input to keep the operation area clean.

- The fan is installed on the bottom of the laminar flow cabinet.

- Though both vertical and horizontal airflow is available, you can only choose to use vertical airflow or horizontal at a time.

Types of Laminar Flow Cabinet

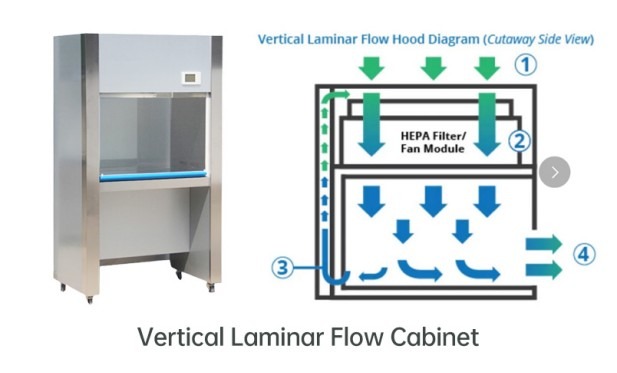

- A vertical flow clean bench is noisier than a horizontal clean bench because its fan is installed at the top. The wind blows vertically so it is often used in medical engineering to ensure the operator’s health. Vertical laminar flow clean bench is widely used in areas requiring partial cleaning, laboratories, biopharmaceuticals, optoelectronics, microelectronics, hard disk manufacturing and other fields.

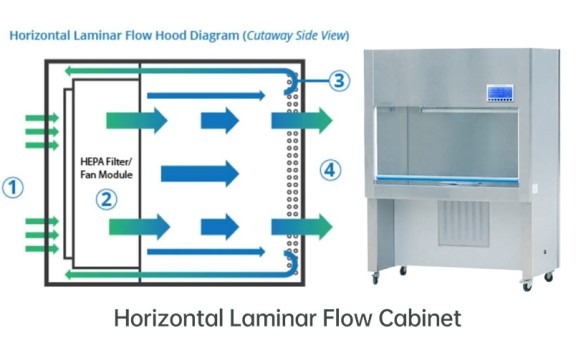

- Horizontal flow clean bench noise is compared small, so it is usually used in the electronic industry, which has little effect on health. Horizontal laminar flow is widely used in electronics, national defense, precision instruments, meters, pharmaceutical industries, etc.

Desktop laminar flow cabinet series

Desktop Laminar Flow Cabinet Vertical Air Flow VD-650 / VD-850

• Clean grade: 100 (209 E U.S. Federal)

• Working area dimension: 485*475*455mm / 685*475*455mm

Desktop Laminar Flow Cabinet – Horizontal Air Flow HD-650 / HD-850

• Clean grade: 100 (209 E U.S. Federal)

• Working area dimension: 485x385x455mm / 685x385x455mm

Vertical laminar flow cabinet series

Vertical Laminar Flow Cabinet SW-CJ-1D

• Clean grade: 100(209 E U.S. Federal)

• Working area

Vertical Laminar Flow Cabinet SW-CJ-1F

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 870*580*515mm

Vertical Laminar Flow Cabinet SW-CJ-1FD

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 870*580*515mm

Horizontal laminar flow cabinet series

Horizontal Laminar Flow Cabinet HS-840U

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 700*560*580mm

Horizontal Laminar Flow Cabinet HS-1300U

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 1140*615*580mm

Vertical and horizontal laminar flow cabinet series

Vertical and Horizontal Laminar Flow Cabinet SW-CJ-1FB / SW-CJ-2FB

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 870*510*600mm/1320*510*600mm

All steel vertical air flow cabinet series

All Steel Vertical Laminar Flow Cabinet SW-CJ-2D

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 1140*700*520mm

All Steel Vertical Laminar Flow Cabinet SW-CJ-1FD

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension: 840*700*520mm

All Steel Vertical Laminar Flow Cabinet SW-CJ-2FD

• Clean grade: 100(209 E U.S. Federal)

• Working area dimension:840*700*520mm

PCR Laminar Flow Cabinet

PCR-1S/2S PCR Laminar Flow Cabinet

• Average wind speed: 0.25~0.45m/s

• Work area size: 700×510×580mm/1150×510×580mm

Application of Laminar Flow Cabinet

The laminar flow clean bench is a work bench or similar enclosure which has its own filtered air supply. The clean bench was developed as an adjunct to cleanroom technology (the need to protect the work from contamination). In recent years, the use of the clean bench, laminar flow cabinet, or laminar flow hood has spread from research and manufacturing to other fields such as aerospace, bioscience, pharmaceutical production, and food processing. Today, laminar flow clean benches are used in a variety of applications throughout medical research laboratories, hospitals, manufacturing facilities, and other research and production environments.

Differences Between Vertical and Horizontal Type Laminar Flow Cabinet

- Vertical type

Airflow path: The air flows vertically downward from the top high-efficiency filter, passes through the working area and is discharged from the bottom return air outlet.

Features:

The airflow coverage area of vertical air supply is large, which is suitable for operations that require a large clean environment, such as biological experiments or drug preparation, and can effectively prevent cross contamination. The airflow forms a “unidirectional laminar flow” from top to bottom, reducing operator interference and suitable for protecting experimental samples (such as cell culture, aseptic operation).

- Horizontal type

Airflow path: The air flows horizontally forward from the rear high-efficiency filter, passes through the working area and is discharged from the front return air outlet.

Features:

The airflow blows directly to the operator, reducing the backflow of pollutants into the working area, which is suitable for scenarios where the operator needs to be protected (such as chemical reagent processing). The operation is more intuitive, there is no top cover, the field of vision is wide, and it is suitable for precision operations (such as electronic component assembly).

Laminar Flow Cabinet Display

Why Choose US?

- Rich categories.

- The products are market-oriented and exported to many countries in the world

- Perfect sales system, efficient and fast after-sales service

- On-time delivery rate reaches 100%

- High-cost performance

Customer Feedback of Laminar Flow Cabinet