In modern laboratory environments, mixing operations are a key link in many experiments and research processes. Whether in chemistry, biology, medicine or materials science, different substances need to be mixed accurately to achieve specific reaction conditions or product requirements. Laboratory mixing equipment plays an indispensable role in this process. They can mix two or more components in a predetermined proportion and manner to ensure the uniformity and accuracy of the mixing, thus laying the foundation for subsequent experimental analysis or product preparation.

What is laboratory mixing equipment?

Laboratory mixing equipment is a tool specially designed to mix different substances in a laboratory environment. These substances can be liquids, solids or gases, and the equipment uses various mechanical or physical means to mix them thoroughly. For example, in chemical experiments, different chemical reagents may need to be mixed for reaction; in biological research, cell culture fluid may need to be mixed evenly with nutrients.

The working principles of laboratory mixing equipment are varied, and the common ones are stirring, shaking, and ultrasound. The stirring mixing equipment stirs the substances in the container through a rotating stirring paddle to promote the mixing of the substances; the shaking mixing equipment achieves mixing through periodic vibration; the ultrasonic mixing equipment uses the cavitation effect of ultrasound to mix substances at the microscopic level.

Then, let’s get to know these different types of mixing equipments.

Types of Laboratory Mixing Equipment

Laboratory mixing equipment can be categorized into three primary types: Stirring Mixing Equipment, Shaking Mixing Equipment, and Homogenizing Mixing Equipment. Each type serves specific purposes and is suited to particular applications.

1. Stirring Mixing Equipment

Stirring mixing equipment is designed to create a smooth, consistent mixture by stirring liquids or low-viscosity substances. These mixers are commonly used for preparing solutions, dilutions, and suspensions.

Common types are:

| Stirring Equipment | Key Features | Applications |

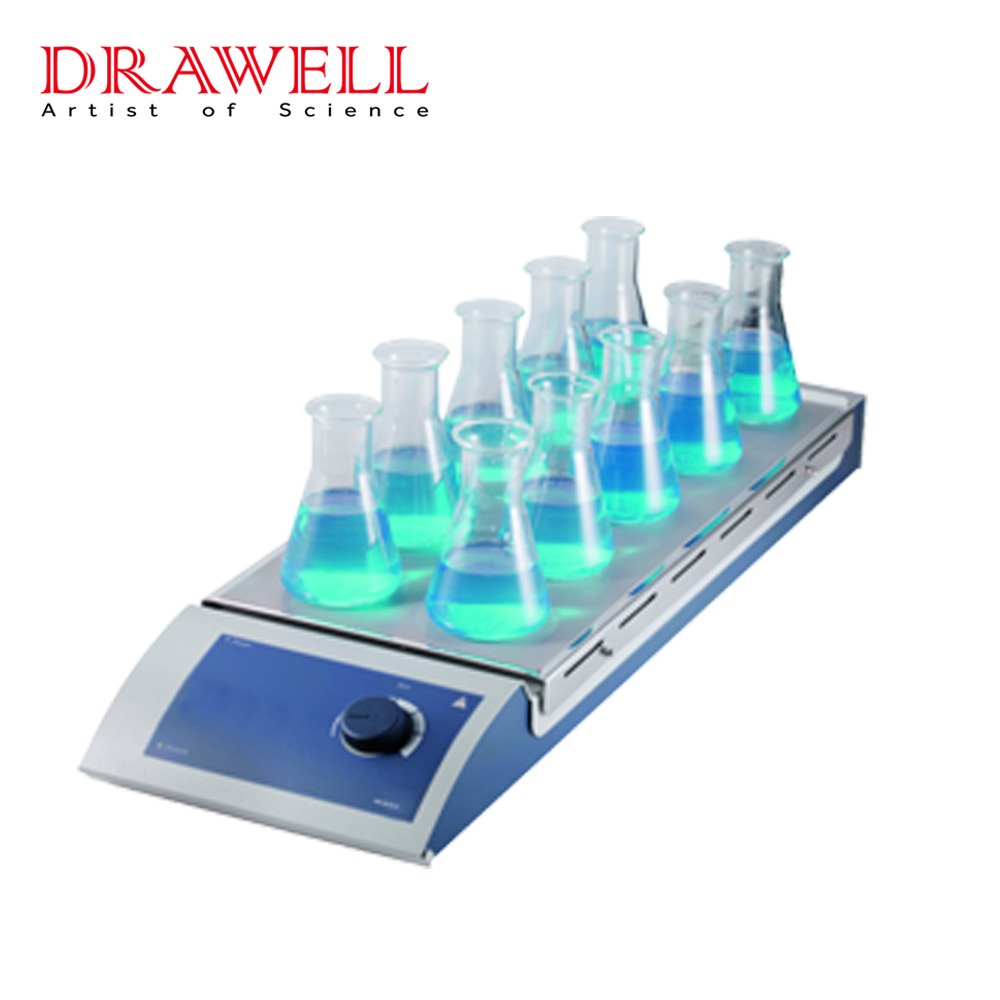

| Magnetic Stirrers | Compact, uses a magnetic field to spin a stir bar, often includes heating options. | Mixing low-viscosity liquids, preparing solutions, and titrations. |

| Overhead Stirrers | Motorized shaft, adjustable speed and torque, handles viscous materials. | Mixing adhesives, resins, and large-volume solutions. |

| Hotplate Stirrers | Combines stirring and heating, with adjustable temperature and speed settings. | Dissolving solids in liquids, preparing culture media. |

2. Shaking Mixing Equipment

Shaking mixing equipment creates motion to mix samples through gentle rocking, oscillation, or vigorous shaking. These mixers are especially useful for suspensions, cell cultures, and reagents requiring aeration or gentle agitation.

Common types are:

| Shaking Equipment | Key Features | Applications |

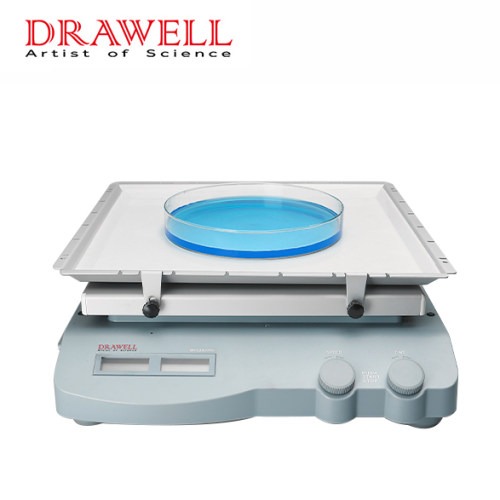

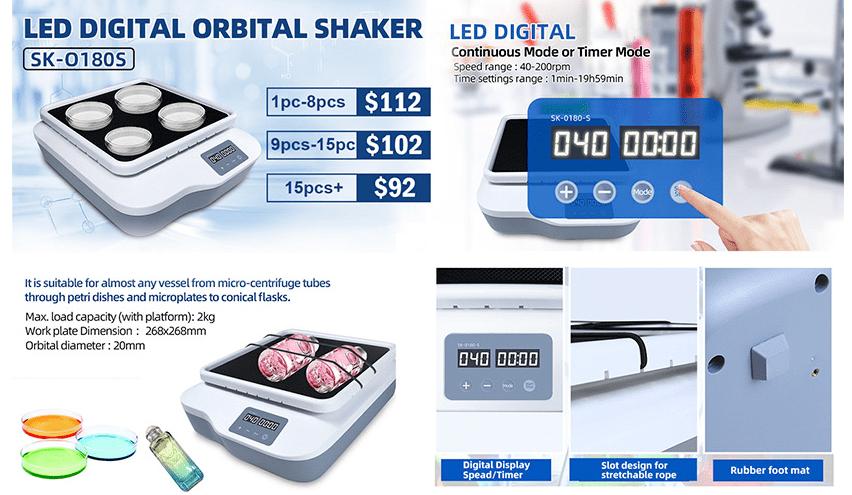

| Orbital Shakers | Circular motion, adjustable speed and amplitude, supports various vessel sizes. | Mixing cell cultures, microbial cultivation, and enzyme reactions. |

| Reciprocating Shakers | Back-and-forth linear motion, consistent for viscous samples. | DNA extraction, protein studies, and suspensions. |

| Rocking Platforms (3D Rockers) | Gentle tilting motion, adjustable tilt and speed. | Staining/destaining gels, hybridization buffers, and blood sample mixing. |

| Vortex Mixers | Rapid circular motion, compact design, suited for small volumes. | Resuspending pellets, mixing reagents in tubes or vials, and molecular biology applications. |

3. Homogenizing Mixing Equipment

Homogenizing mixing equipment is designed to break down and blend materials into uniform, fine particles or emulsions. This category is essential for high-precision applications like tissue homogenization and emulsion preparation.

Common types are:

| Specific Equipment | Key Features | Applications |

| High-Speed Homogenizers | Rotors and stators for shear forces, adjustable speed, handles various viscosities. | Tissue homogenization, emulsions, and dispersions in pharmaceuticals and cosmetics. |

| Ultrasonic Homogenizers | Uses ultrasonic waves, compact and precise, effective for nanoparticle creation. | Cell lysis, nanoemulsion preparation, and dispersing powders into liquids. |

| Bead Mill Homogenizers | Uses beads and agitation to break tough samples, suitable for small volumes. | Tissue disruption for genomic and proteomic studies, processing seeds, and bone samples. |

| Pressure Homogenizers | High-pressure system, creates fine suspensions and emulsions. | Producing stable emulsions, food and pharmaceutical formulations. |

In a summary, each type has unique strengths.

- Stirring Mixing Equipment: Best for low-viscosity liquids and solutions requiring controlled stirring.

- Shaking Mixing Equipment: Ideal for gentle or vigorous mixing of samples in plates, tubes, or flasks.

- Homogenizing Mixing Equipment: Critical for breaking down materials into fine particles or emulsions.

Choosing the right mixing equipment depends on the application, sample type, and desired results.

Factors to Consider When Choosing Laboratory Mixing Equipment

When selecting the ideal mixing equipment for your lab, it’s essential to evaluate key aspects such as material properties, mixing requirements, sample capacity, and equipment cost and maintenance. Here are the details:

1. Material Properties

Viscosity: The viscosity of your material determines the type of mixer required. For low-viscosity liquids, magnetic stirrers or orbital shakers are suitable. For high-viscosity samples, overhead stirrers or high-speed homogenizers are better options.

Reactivity and Chemical Compatibility: Ensure the equipment components (e.g., impellers, stir bars) are resistant to corrosive or reactive chemicals. Stainless steel, PTFE-coated, or chemically resistant plastics are good material choices.

Thermal Sensitivity: For heat-sensitive materials, choose mixers with controlled-temperature settings or cooling systems.

2. Mixing Requirements

Type of Mixing: Determine whether your process requires stirring, shaking, or homogenizing. Stirring is suitable for simple blending, while homogenizers are essential for emulsifying or breaking down complex samples.

Mixing Speed and Precision: Adjustable speed and precise controls are critical for experiments needing fine-tuned mixing conditions. Look for digital interfaces for enhanced accuracy in critical applications.

Mixing Intensity: For gentle mixing, consider rockers or orbital shakers. For vigorous or high-shear mixing, high-speed homogenizers or vortex mixers are more appropriate.

3. Sample Capacity

Volume Range: Choose equipment that accommodates your typical sample sizes. For small volumes, compact equipment like vortex mixers or magnetic stirrers is ideal. For large volumes, opt for overhead stirrers or industrial-grade homogenizers.

Scalability: If your workflow involves scaling up experiments, ensure the equipment can handle increasing sample volumes.

Multiple Samples: For processing multiple samples simultaneously, consider multi-position mixers or shakers with large platforms.

4. Equipment Cost and Maintenance

Initial Investment: Please balance cost with functionality. High-end models may offer advanced features, but simpler equipment often suffices for basic tasks.

Operational Costs: Evaluate energy efficiency and potential long-term savings. Equipment with low maintenance needs often provides better value over time.

Durability: Invest in robust, long-lasting equipment made from high-quality materials. Avoid frequent replacements by choosing brands with a reputation for reliability.

Ease of Maintenance: Opt for designs that are easy to clean and have readily available replacement parts. Regular maintenance schedules can extend the lifespan of your equipment.

Considering the material properties, mixing requirements, sample capacity, and cost-effectiveness of equipment is crucial to making an informed choice. By aligning your selection with your laboratory’s specific needs and budget, you ensure optimal performance, durability, and efficiency in your mixing processes.

Frequently Asked Questions (FAQs)

Q1: What is the difference between magnetic and overhead stirrers?

Magnetic stirrers are compact and suited for low-viscosity liquids, while overhead stirrers handle larger volumes and viscous materials.

Q2: Can one type of mixer be used for all applications?

No, each type is specialized. For example, vortex mixers are for small samples, while homogenizers work for complex mixtures.

Q3: How do I choose the right stir bar for my magnetic stirrer?

The size and shape of the stir bar should be appropriate for the vessel size and liquid volume.

Q4: Can I use a vortex mixer for large volumes?

Vortex mixers are primarily designed for small-volume mixing. For larger volumes, consider using an orbital shaker or overhead stirrer.

Q5: My material is high viscosity and contains solid particles. Which mixing equipment should I choose?

In this case, you can consider a stirring mixer with a special stirring paddle (such as a large gap stirring paddle) or an ultrasonic mixer. The stirring mixer can drive the solid particles to move by rotating the stirring paddle to prevent agglomeration, while the ultrasonic mixer can use the cavitation effect to mix high-viscosity materials evenly at the micro level.

Q6: I am in a biological laboratory and mainly deal with small-volume samples. Which mixing equipment causes the least damage to cells?

When dealing with small-volume samples in a biological laboratory, the shaking mixer causes relatively less damage to cells. Because its mixing method is through gentle shaking, unlike the stirring paddle of the stirring mixer, which may produce mechanical shear force on the cells, and unlike the ultrasonic mixer, which may damage the cells due to ultrasound.

Laboratory mixing equipment is of great significance in various scientific experiments and research. When choosing the right mixing equipment, you should fully understand the characteristics of different types of equipment and consider factors such as material properties, mixing requirements, sample capacity, equipment cost and maintenance. At the same time, you should have a clear understanding of the common problems that may be encountered during use, so as to ensure that the mixing operation is completed efficiently and accurately in the laboratory, providing a good foundation for subsequent experiments or product preparation. If you have any laboratory equipment procurement needs, please feel free to contact us. Drawell is a professional laboratory equipment supplier.