Vacuum Drying Oven

What is Vacuum Drying Oven?

The vacuum drying oven is an earlier drying device, and the inside of the oven is divided into several layers by heating plates. Hot water or low-pressure steam is passed into the heating plate as the heating medium, the material pan with the medicine to be dried is placed on the heating plate, the door of the box is closed, and the inside of the box is vacuumed with a vacuum pump. The heating plate heats the medicine to the specified temperature in the circulating flow of the heating medium, and the water starts to evaporate and is gradually drawn away with the vacuum. This equipment is easy to control, can condense and recover the evaporated solvent, and the medicine is not easy to be contaminated during the drying process. It can be used for medicine drying, packaging material sterilization, and heat treatment.

Features of Vacuum Drying Oven

- Microprocessor controller with LCD display, more accurate and reliable.

- Polished stainless steel chamber, durable and easy to clean.

- A tempered, bullet-proof double glass door ensures the safety of the operator and clear observation of the chamber.

- Door tightness can be adjusted, and silicon sealing. To keep vacuum states in the chamber can fill a working chamber with inert gas (inflation pressure ɗ 0.1 MPa).

- Storage, heating, testing, and drying can be performed in an environment without oxygen or in an inert atmosphere. It will not cause oxidation.

- Equipped with leakage protection.

- Vacuum degrees can be displayed and full-automatic controlled by a microcomputer for LC types.

Applications of Vacuum Drying Oven

Drawell Vacuum Drying Oven is suitable for industrial and mining enterprises, medical colleges, and scientific research institutions to conduct drying and heating treatment tests on objects under vacuum conditions. It is specially designed for drying heat-sensitive, easy-decomposable, and easy-to-oxidize products. It can fill the studio with inert gas. Especially for some items with complex compositions, they can be dried quickly.

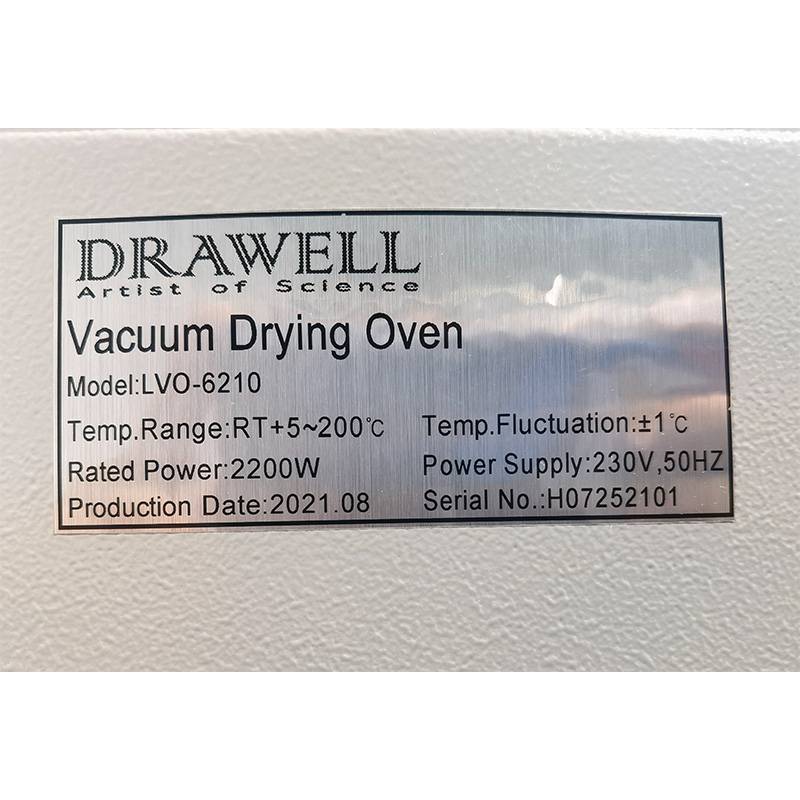

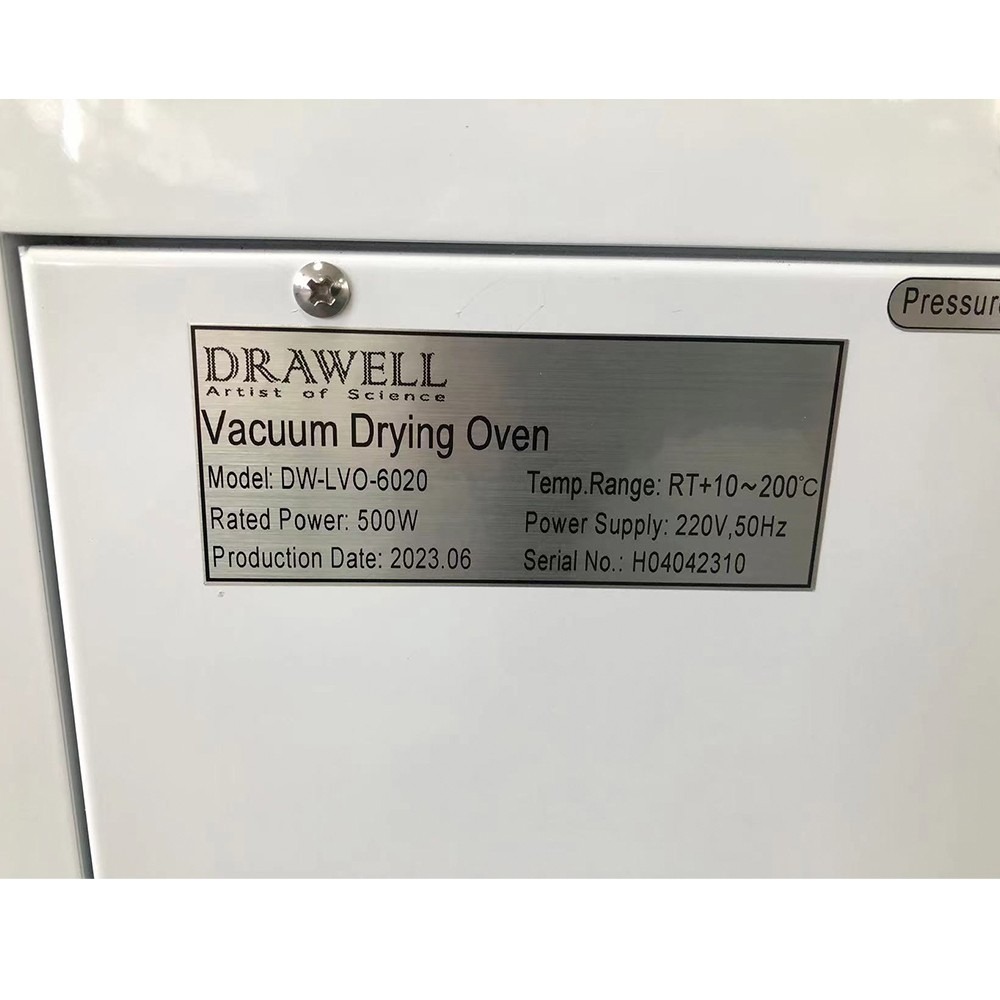

Specifications of the Vacuum Drying Oven

| Model | DW-LVO-1B(6050) | DW-LVO-0B(6020) | DW-LVO-6090 | DW-LVO-6210 |

| Image |  |  |  |  |

| Power Supply | AC 220V, 50Hz | |||

| Volume(L) | 54L | 25L | 91L | 215L |

| Power Rating(kw) | 1.4kw | 0.5kw | 1.6kw | 2.2kw |

| Temperature Range(℃) | RT+5 ~250℃ | RT+5 ~200 | ||

| Temperature Fluctuation(℃) | ±1℃ | |||

| Display Resolution(℃) | 0.1℃ | |||

| Vacuum Pressure | <133 Pa | |||

| Chamber Size (W×D×H)cm | 42×35×37 | 30×30×28 | 45×45×45 | 56×60×64 |

| Exterior Size (W×D×H)cm | 71×59×53 | 58×57×45 | 61×66×145 | 72×82×175 |

| Package Size(W×D×H)cm | 82×70×69 | 70×64×60 | 78×76×163 | 89×92×193 |

| Net/Gross Weight(kg) | 75/106 | 35/50 | 90/145 | 145/195 |

| Model | DW-LVO-1B(6050) | DW-LVO-0B(6020) | DW-LVO-6090 |

| Image |  |  |  |

| Power Supply | AC 220V, 50Hz | ||

| Volume(L) | 50L | 91L | 215L |

| Power Rating(KW) | 1.4kw | 1.6kw | 2.2kw |

| Temperature Range(℃) | RT+10~250 | RT+10~200 | |

| Temperature Fluctuation | ±1℃ | ||

| Display Resolution | 0.1℃ | ||

| Vacuum Degree | <133 Pa | ||

| Chamber Size (W×D×H)cm | 42×35×37 | 45×45×45 | 56×60×64 |

| Exterior Size (W×D×H)cm | 53×56×137 | 61×66×145 | 72×82×175 |

| Package Size (W×D×H)cm | 70×66×155 | 78×76×163 | 89×92×193 |

| Net/Gross(kg) | 75/106 | 90/145 | 145/195 |

Vacuum Drying Oven Display

Vertical Vacuum Drying Oven

Desktop Vacuum Drying Oven

How to Choose Vacuum Drying Oven?

1. Temperature range

- Requirement matching: Select according to the maximum temperature required for experiment or production, the common range is from room temperature to 200°C or higher.

- Accuracy requirements: Ensure that the temperature control accuracy meets the requirements, usually ±1°C or higher.

2. Vacuum degree

- Vacuum degree requirements: Select according to the characteristics of the sample, the common range is from low vacuum (10^-3 mbar) to high vacuum (10^-6 mbar).

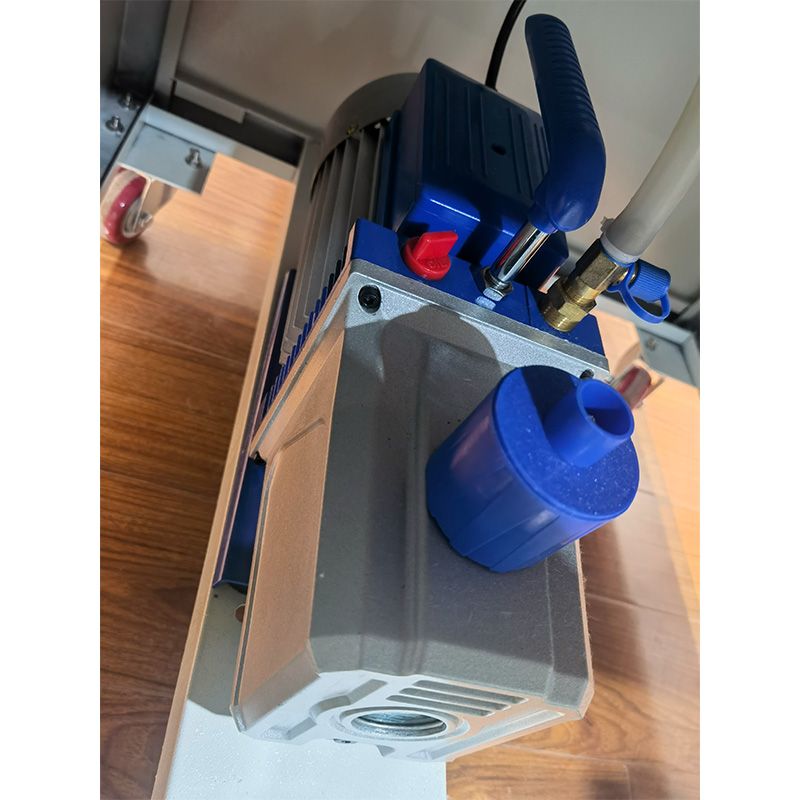

- Vacuum pump selection: Select a suitable vacuum pump according to the vacuum degree requirements, such as rotary vane pump, molecular pump, etc.

3. Volume

- Sample volume: Select the appropriate volume according to the size and quantity of the sample, the common specifications range from 20L to 200L.

- Space utilization: Ensure that the internal space design is reasonable and convenient for sample placement.

4. Material

- Inner tank material: The common material is stainless steel, which is corrosion-resistant and easy to clean.

- Sealing material: Ensure that the sealing ring is resistant to high temperature and corrosion, commonly used silicone or fluororubber.

5. Control system

- Control mode: Choose digital control or analog control, digital control has higher accuracy.

- Function: It has functions such as timing, program control, data recording, etc. to improve the convenience of operation.

6. Safety performance

- Over-temperature protection: Ensure that there is an over-temperature protection device to prevent the temperature from being too high.

- Vacuum safety: Equipped with vacuum degree monitoring and alarm functions to ensure safe operation.