Infrared Fast Drying Oven

What is Infrared Fast Drying Oven?

The principle of the Far Infrared Drying Oven is that the far-infrared heating tube is located in the air ducts on both sides of the Far-Infrared Drying Oven. According to the requirements of the material and the difference in temperature, it can be divided into top heating, bottom heating, and left and right simultaneous heating. The heating power can be controlled by switch groups. The motor delivers air through the air duct with strong pressure to make the internal temperature of the oven uniform. So as to obtain the effect of rapid drying, achieve the purpose of shortening the production cycle, saving energy, and improving product quality.

Features of Infrared Fast Drying Oven

- Equipped with far-infrared heating radiator, and temperature control.

- Microprocessor controller(with temperature correction and timing function).

- Large LCD screen display.

- High-quality stainless steel chamber, removable shelf, easy to clean.

- Equipped with multiple sets of heaters.

- Adopt a temperature selection switch that can select the grade according to the heating speed and operating temperature.

- Convenient operation for air inlet, reasonable air duct structure, good temperature uniformity.

- Silicone sealing ring for reliable sealing.

- With an inner glass door for easy observation.

- Equipped with leakage protection.

- Equipped with spare temperature control which ensures the product work normally even at the main temp. control failed.

- Optional printer or RS485 interface which can print or connect a computer for remote control and alarm.

- Anti-hot handle

Applications of Infrared Fast Drying Oven

The product adopts high-efficiency and low-consumption far-infrared heating new technology, which has a good effect on fast drying work and test samples. It can be widely used in industrial, agricultural, medical, and scientific research projects and laboratories.

DRAWELL’s Infrared Fast Drying Oven

DW-LIO Infrared Fast Drying Oven

• Temp. Range: RT+10 ~250℃

• Shelf:2

Specifications of the Product

| Model | DW-LIO-300 | DW-LIO-400 | DW-LIO-500 | DW-LIO-600 |

| Image |  |  |  |  |

| Power Supply | AC 220V, 50Hz | |||

| Temperature Range(℃) | RT+10 ~250℃ | |||

| Shelf | 2 | 2 | 2 | 2 |

| Chamber Size (W×D×H)cm | 35×35×35 | 45×40×45 | 50×50×55 | 60×60×70 |

| Exterior Size (W×D×H)cm | 64×50×60 | 73×53×69 | 78×69×80 | 88×73×95 |

| Package Size(W×D×H)cm | 75×57×84 | 86×60×90 | 96×70×100 | 106×80×110 |

| Net/Gross Weight(kg) | 36 / 56 | 51 / 81 | 76 /111 | 111/151 |

| Power Rating(W) | 1400 | 2000 | 2800 | 4000 |

Products Display

How to Choose Infrared Drying Oven?

1. Temperature range

Demand matching: Select the appropriate range according to the temperature required for material drying. Far-infrared drying ovens are usually between 50°C and 300°C.

2. Heating method

Far-infrared heating: Far-infrared heating has high efficiency and strong penetration, and is suitable for rapid drying.

Uniformity: Ensure uniform heating to avoid local overheating or uneven drying.

3. Box material

Inner liner material: Stainless steel is corrosion-resistant and easy to clean, suitable for high temperature and corrosive environments.

Outer shell material: Cold-rolled steel plate spraying or stainless steel to ensure durability and beauty.

4. Control system

Temperature control accuracy: Choose a high-precision temperature control system to ensure stable temperature.

Operation interface: Touch screen or digital display, easy to operate.

5. Safety performance

Overheat protection: With overheating automatic power-off function.

Explosion-proof design: If handling flammable and explosive materials, you need to choose an explosion-proof type.

6. Capacity and size

Capacity selection: select the appropriate box capacity according to the amount of material.

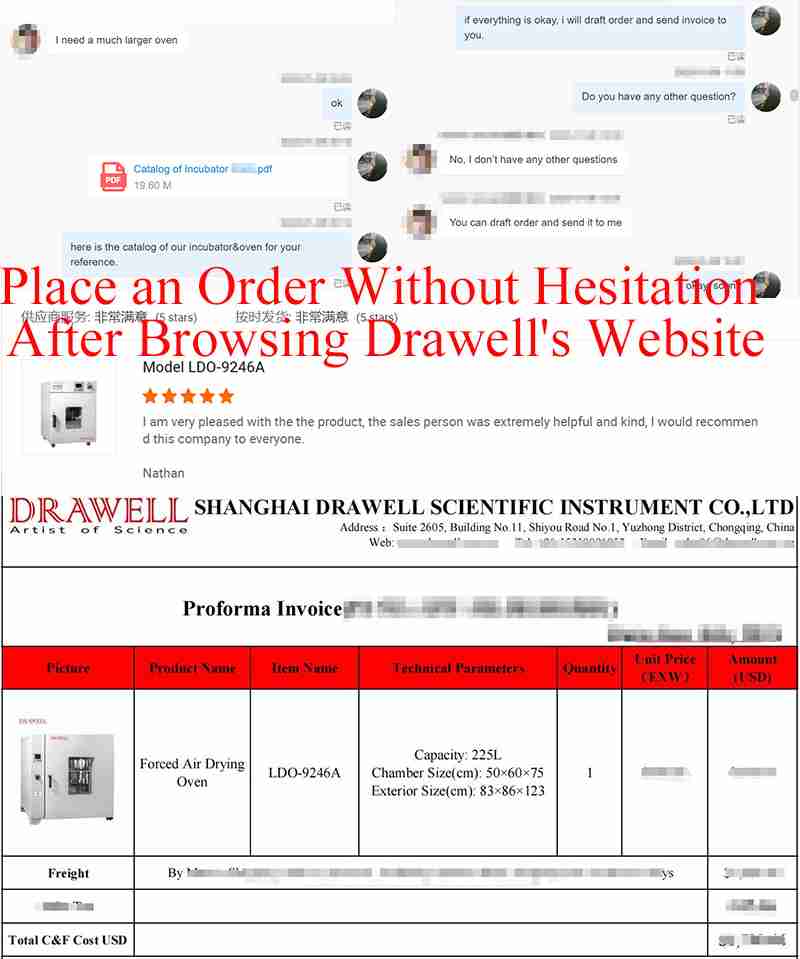

Customer Feedback of Drying Oven