Illumination Incubator

What is Illumination Incubator/Light Chamber?

Illumination Incubator is a device used to simulate environmental conditions such as light, temperature and humidity. It is mainly used for experiments and research on plant growth, seed germination, microbial cultivation, etc.

Features of Illumination Incubator/Light Chamber

- Adopt imported fluorine-free compressor, environment friendly and reliable.

- Adopt mirror stainless steel inner tank, shelves inside the chambers can be freely adjustable without tool, convenient for disinfection and cleaning

- Double door design, tempered glass inner door,

- Menu operation, multi-segment programmable control.

- Independent temperature limit alarm system, giving sound and light alarm to prompt operator to ensure safe operation.

- Equipped with leakage protector and auxiliary thermostat.

LB-N Light Chamber(Fluorine-free Refrigeration)

•Temp.Range: with light:10~55℃, without light:0~55℃

•Ambient Temperature: +5~35℃

Applications of Illumination Incubator/Light Chamber

- Plant research: used for seed germination, plant growth and photosynthesis research.

- Microbial culture: culture bacteria, fungi and other microorganisms.

- Environmental simulation: simulate different climatic conditions to study the adaptability of organisms.

- Biotechnology: used for cell culture, tissue culture and other experiments.

How to Choose Illumination Incubator?

1. Light requirements

- Light intensity: Select the appropriate light intensity according to the experimental requirements, usually in μmol/m²/s or lux.

- Spectral range: Make sure the light source can provide the required spectrum, such as red light, blue light or full spectrum.

- Uniformity: The light should be evenly distributed to avoid local over-intensity or under-intensity.

2. Temperature control

- Temperature range: Select the appropriate temperature range according to the experimental requirements, usually 5°C to 50°C.

- Control accuracy: The temperature fluctuation should be as small as possible, usually within ±0.5°C.

3. Humidity control

- Humidity range: Select the humidity range according to the experimental requirements, usually 50% to 95% RH.

- Control accuracy: The humidity fluctuation should be as small as possible, usually within ±5% RH.

4. CO2 control

- CO2 concentration: If CO2 control is required, choose a model with adjustable CO2 concentration, usually in the range of 0-2000 ppm.

- Control accuracy: CO2 concentration fluctuations should be as small as possible, usually within ±50 ppm.

5. Capacity and space

- Internal space: Select the appropriate capacity according to the scale of the experiment to ensure sufficient space for samples.

- Interval design: The interval should be adjustable to facilitate the placement of culture containers of different heights.

6. Control system

- Operation interface: Select an easy-to-operate interface, such as a touch screen or digital control panel.

- Program control: Support multi-stage program control, which is convenient for setting different parameters such as light, temperature, humidity, etc.

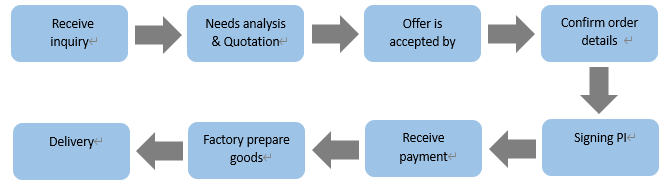

Order Process

Why Choose Us?

- Rich categories and high quality

- The products are market-oriented and exported to many countries in the world

- Perfect sales system, efficient and fast after-sales service

- On-time delivery rate reaches 100%

- High cost performance