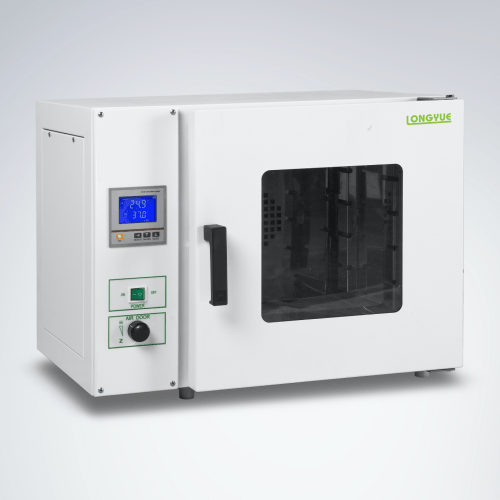

Hot Air Sterilizer

What is Hot Air Sterilizer?

Hot air sterilizer is a device that uses high-temperature hot air for sterilization, mainly used to kill microorganisms on the surface of objects, such as bacteria, viruses, etc. Its working principle is to heat the air to a certain temperature and maintain it for a period of time to achieve the sterilization effect.

Features of Hot Air Sterilizer

- Mirror stainless steel chamber, with observation window, safe and convenient.

- High accuracy:Micro-computer control, LCD display, accurate and reliable.3.High efficiency: fast heating with forced convection, save more time.

- Two sets over-temperature protection system, automatically stops when exceed the temp limit.

- Equipped with leakage protector.

- Easy operation: The fan speed and timing function can be easily set in the meter.

- Movable shelf, easy for cleaning.

DW-LAS-A Series Hot Air Sterilizer

• Temp. Range: RT+10~250℃

• Temp. Resolution: 0.1℃

• Shelf: 2 / 3

Applications of Hot Air Sterilizer

- Laboratory: Sterilize glassware, metal tools, etc.

- Medical industry: Sterilize medical devices.

- Food industry: Sterilize food processing tools and containers

How to Choose Hot Air Sterilizer?

1. Temperature Range

- Applicability: Make sure the sterilizer can reach the required temperature, usually between 160°C and 180°C, to meet the sterilization requirements of different items.

- Precise control: Choose equipment with precise temperature control to ensure the sterilization effect.

2. Capacity

- Item size: Choose the appropriate capacity according to the volume of the items to be sterilized, avoiding too large or too small.

- Frequency of use: When used frequently, it is recommended to choose a larger capacity to improve efficiency.

3. Material and Structure

- Inner tank material: Stainless steel is preferred because it is resistant to high temperatures and easy to clean.

- Sealing: A good sealing design can ensure uniform temperature distribution and improve the sterilization effect.

4. Safety

- Overheat protection: The equipment should have an overheat protection function to prevent danger caused by excessively high temperatures.

- Anti-scalding design: The outer shell should be insulated to avoid burns during operation.

5. Convenience of Operation

- Control panel: Choose equipment with simple operation and clear display.

- Timing Function: The timing function helps to automate the disinfection process and save time.

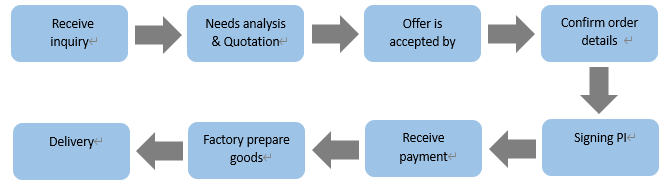

Order Process

Why Choose Us?

- Rich categories and high quality

- The products are market-oriented and exported to many countries in the world

- Perfect sales system, efficient and fast after-sales service

- On-time delivery rate reaches 100%

- High cost performance