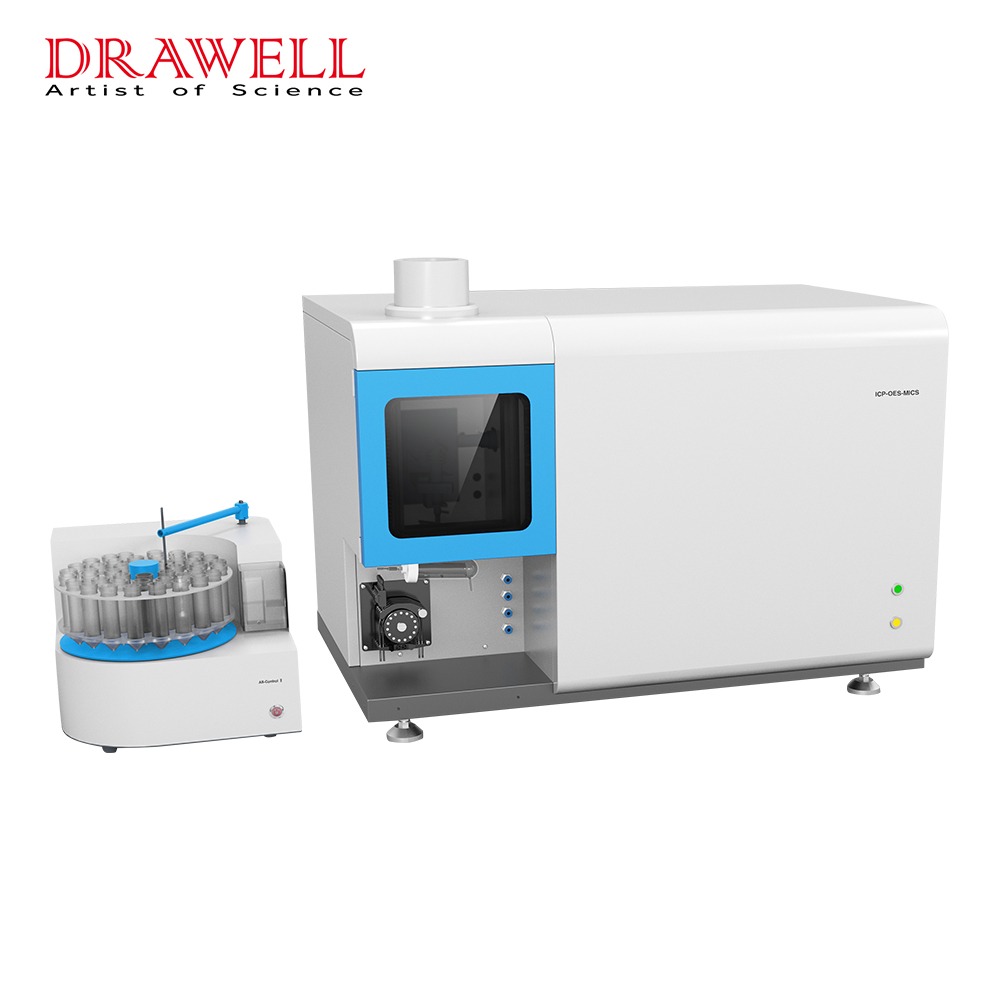

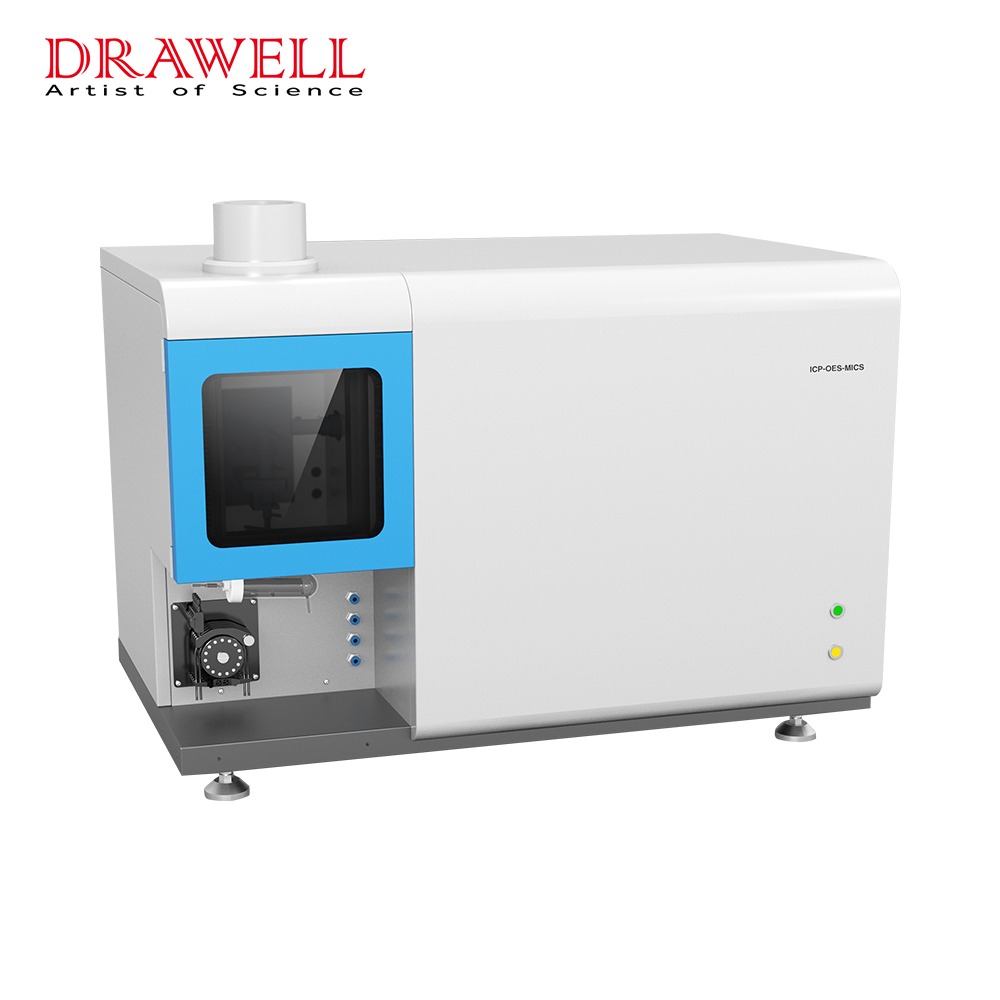

ICP-OES MICS Full Spectrum Direct Reading Inductively Coupled Plasma Emission Spectrometer

The full spectrum direct reading inductively coupled plasma emission spectrometer utilizes a reliable integrated solid-state RF power supply, a stable constant temperature two-dimensional spectroscopic system, and a scientific research level refrigeration anti overflow CCD detection system. Combined with leading spectral correction technology in China, the operability, flexibility, and reliability of the spectrometer are beyond imagination. Daily operation and maintenance are very simple, making it more suitable for the operational requirements of frontline analytical experiments in China, Implement Minimization, Intelligentize, and Convention Spectrometers.

The fill spectrum direct reading inductively coupled plasma emission spectrometer can be widely used in various fields such as environmental protection, food safety, geology and mineral resources, metallurgy, nonferrous metals, rare earths, chemical engineering, clinical medicine, petroleum products, semiconductors, agricultural research, etc. Used to determine the content of major, trace, and trace elements in different substances. It can be used for qualitative, semi quantitative, and precise quantitative analysis of elements in samples, with a detection limit of up to one billion parts.

Features of ICP-OES MICS Full Spectrum Direct Reading ICP Emission Spectrometer

- High degree of instrument automation

The automation level of the instrument is extremely high, and all operations except for the power switch are completed by software. Intelligent software that can provide real-time feedback and information prompts for various operations

- One second positioning of torch tube position

The torch tube auxiliary installation tool using patented technology can accurately achieve a concentric circle structure between the torch tube and the coil position, while ensuring that there is no deviation in the position and ensuring the stability of the test signal.

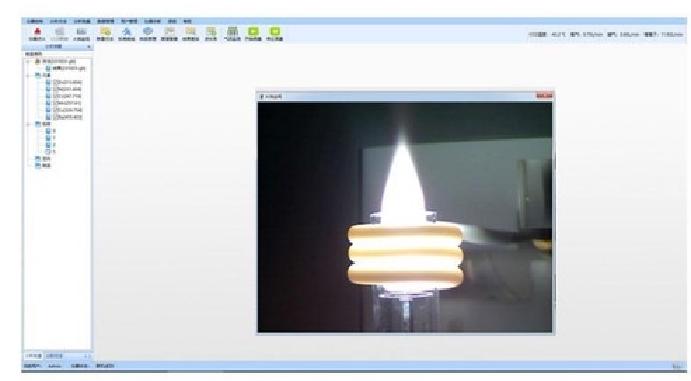

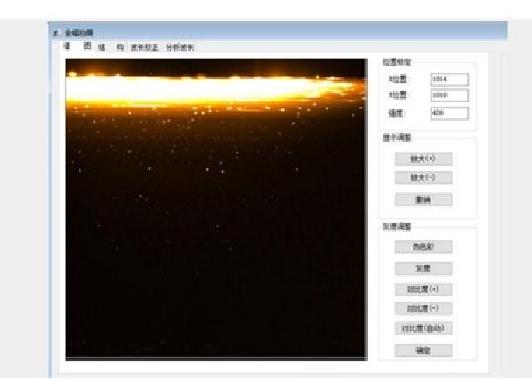

- Real time monitoring system for plasma flames

Equipped with a real-time full color camera system, the operator can see the running graphics of the plasma in real-time full color in the control software of the instrument, and observe whether the torch tube and the center tube of the torch tube are dirty and need to be cleaned.

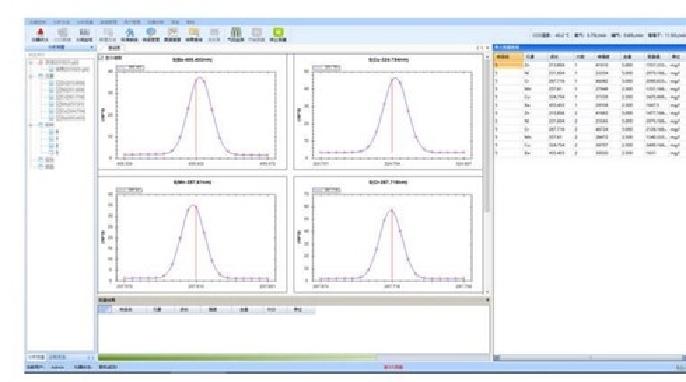

- Testing speed beyond imagination

A testing speed of 20s can be set to an appropriate integration time for measurement. The integrated intensity values of all analytical spectral lines can be read out in one exposure. Accurate measurement of nearly 70 elements in a single sample within one minute.

- Convenient wavelength calibration function

Intelligent automatic wavelength calibration algorithm, the software automatically performs wavelength calibration after startup, greatly saving time and cost for wavelength calibration.

- Fully automatic ignition and matching technology

The software can fully automatically ignite with one click, and all parameter settings are automatically changed. With advanced automatic matching technology, the ignition success rate is high and the operation is simple.

- Separate injection system

The split design of the fog chamber and torch tube reduces the impact of temperature changes in the combustion chamber on atomization efficiency, making it more intuitive to observe the real-time injection status. Equipped with patented technology, the extended mist chamber effectively separates gas and liquid, reducing interference from water vapor.

- Precision spectroscopic system

By using a mid step grating combined with prism cross dispersion splitting method, precise optical design can achieve maximum luminous flux and excellent spectral resolution.

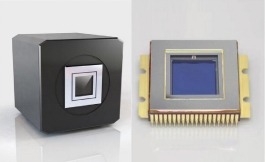

- Scientific research level large format CCD detector

Adopting a self-developed CCD detection system with millions of pixels. Full coverage of 160-900nm wavelength range, single exposure, simultaneous detection of all elements.

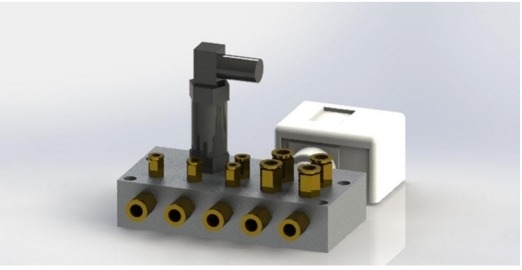

- Safe and reliable airflow protection function

The instrument is equipped with an argon gas monitoring and protection device. When the argon gas is below the safety limit for use, the instrument will automatically turn off the working power and immediately issue an alarm reminder to avoid damage to the equipment due to the depletion of argon gas.

- Safe and reliable solid-state RF power supply

The RF power supply used in the instrument has small size, high output efficiency, stable output power, and various safety protection functions such as water, gas, and overload, greatly improving the safety of the instrument and reducing its failure rate.

- Intelligent flame monitoring function

The instrument is equipped with highly sensitive fiber optic sensors, which can monitor the working status of the flame in real-time while the instrument is in operation. In case of abnormal flameout, the instrument can be automatically turned off.

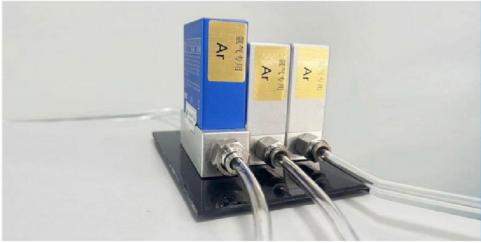

- High precision airflow control system

The plasma gas, auxiliary gas, and carrier gas in the instrument work are all controlled by high-precision mass flow controllers (MFCs), which have continuous adjustable flow rate and high accuracy of output airflow, ensuring the accuracy of test data.

- Peristaltic pump injection device

The peristaltic pump is a five channel sixteen rotor fully automatic design, and the rotational speed of the peristaltic pump can be adjusted according to the required flow rate. It can meet the special usage requirements of customers for online sample dilution and online addition of internal standards.

Applications of ICP-OES MICS Full Spectrum Direct Reading ICP Emission Spectrometer

- Geological mineral: Accurately and quickly analyzing the element content in the mine has strict guiding significance for the early mining, mid-term control, and later repair of the mine.

- Precious metal: The content ofimpurity elements in precious metals directly affects the purity and performance of precious metals, and determines the value of precious metals themselves. Accurately measuring the content of low impurity elements is extremely important for the precious metal industry.

- Environmental protection: Accurately and quickly analyze heavy metal elements in environmental samples(water quality, soil), providing protection for human daily life.

- Petrifaction: Accurately measure the element content in petrochemical products (gasoline, diesel, lubricating oil), analyze the elements of raw materials and finished products in the chemical industry, and ensure that the production process complies with quality control.

- Toy: Analyze the heavy metal elements in children’s toys to ensure that the content of heavy metal elements in the products produced is within the control range, making parents and children more confident.

- Metallurgy: The analysis of product ingredients can control the production process and process in real-time, ensuring the ingredient content of the final product and ensuring the quality requirements of the final product.

Specifications of ICP-OES MICS Full Spectrum Direct Reading ICP Emission Spectrometer

| High-frequency generator | |

| Circuit type | All solid-state RF power supply Input power supply: 220V, 30A |

| Operating Frequency | 27.12MHz |

| Frequency Stability | <0.01% |

| Output power | 800W~1500W |

| Output power stability | ≤0.01% |

| Electromagnetic field leakage radiation intensity | At a distance of 30cm from the chassis, electric field: E< 10V/m: Magnetic field: H < 0.2A/m |

| Gas control flow rate size | Plasma gas flow meter:(l~20)L/min Auxiliary gas flow meter.(0.05~1.0)L/minCarrier gas flow meter :(0.05~1.0)L/min |

| Cooling water | The water temperature range is 20 °C~25 °C, the flow rate is greater than 7 L/min, the water pressure is greater than 0.1MPa, and the cooling water resistance is greater than 1MΩ |

| Polychromator | |

| light path | Middle step grating+prism cross dispersion type |

| Focal length | 440mm |

| Grating specifications | Echelle grating |

| Wavelength range | 175nm~870nm |

| Nitrogen purge | High speed blowing 6L/min, normal blowing 2L/min |

| CCD | |

| Detection wavelength range | l65nm ~ 900nm |

| Quantum efficiency | >30%@200nm |

| Refrigeration temperature | -45℃ |

| Nitrogen purging flow rate | 3L/min |

| Technical indicators of the entire machine | |

| Wavelength range | 175nm~900nm |

| Repeatability | Relative standard deviation RSD < l.5 % |

| Stability | Relative standard deviation RSD < l.0 % |