Inductively Coupled Plasma (ICP) techniques are widely used in elemental analysis across various industries. Among the most common methods are ICP Optical Emission Spectrometry (ICP-OES), ICP Atomic Emission Spectrometry (ICP-AES), and ICP Mass Spectrometry (ICP-MS). These techniques differ in their principles, sensitivity, and applications, making them suitable for different analytical needs. This article explores their working principles, core parameters, and preferred application fields, along with a guide on selecting the right technique based on requirements and cost considerations.

Comparison of Technical Principles and Core Parameters

Working Principle

ICP-OES/AES: These techniques use a high-temperature plasma (6,000–10,000 K) to excite atoms, which then emit light at characteristic wavelengths. The intensity of emitted light correlates with the element’s concentration.

ICP-MS: Instead of optical emission, ICP-MS ionizes atoms and separates them by mass-to-charge ratio using a mass spectrometer, allowing for ultra-trace detection.

Key Performance Parameters

| Parameter | ICP-OES/AES | ICP-MS |

| Detection Limit | 0.1 ppb – 1 ppm | 0.001 – 0.1 ppb |

| Linear Range | 10⁵ | 10⁸ |

| Isotope Analysis | No | Yes (precision: 0.1% RSD) |

| Throughput | 30 samples/hour | 10–20 samples/hour |

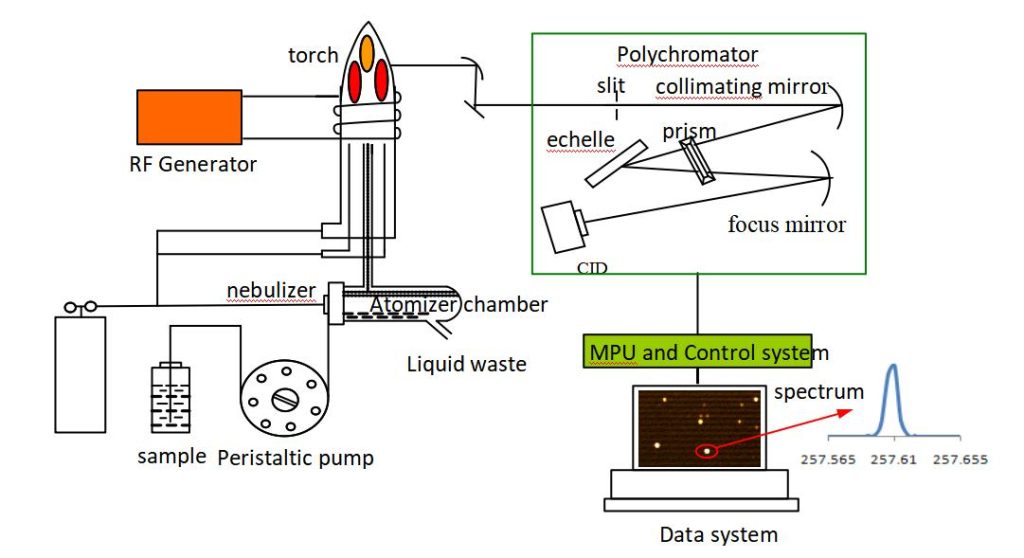

Typical Instrument Structure:

Both techniques share a similar ICP source, but differ significantly in their detection systems.

ICP-OES/AES: Includes a nebulizer(for aerosol generation), plasma torch, monochromator, and detector.

ICP-MS: Features an interface cone (to extract ions), a quadrupole mass filter, and a collision/reaction cell (to reduce interferences).

In essence, while both techniques leverage the powerful ICP source, their distinct detection systems dictate their respective strengths. ICP-OES/AES excels in analyzing major and minor elements with robustness, while ICP-MS reigns supreme in trace and ultra-trace analysis, as well as isotopic determination.

What Are Their Preferred Applications?

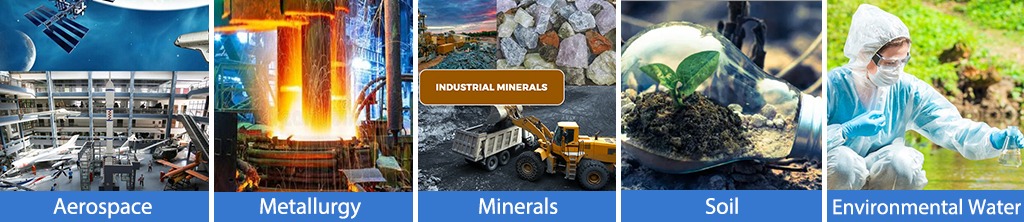

Priority Application of ICP-OES/AES:

ICP-AES application

Environmental Monitoring:

ICP-OES/AES is widely used for routine monitoring of water, soil, and air quality. It reliably measures major and minor elements like calcium, magnesium, and heavy metals at relevant concentrations. For instance, the U.S. EPA Method 200.7 mandates ICP-OES for wastewater compliance testing. A 2024 report showed 85% of municipal labs use ICP-OES for rapid screening (10-minute runtime per sample).

Industrial Materials:

ICP-OES/AES is essential for quality control in industries like metallurgy, ceramics, and glass manufacturing. It enables the precise determination of elemental composition in raw materials and finished products, ensuring consistent quality.

Steel manufacturers rely on ICP-OES to quantify alloying elements (e.g., Mn, Cr) with ±1% accuracy. A case study from Tata Steel demonstrated 98% correlation between ICP-OES and XRF for Fe content analysis, but ICP-OES provided lower detection limits (0.01 ppm vs. 1 ppm).

Food Safety:

ICP-OES/AES plays a role in analyzing food products for nutrient content and potential contaminants. It can detect nutritional elements (Ca, Mg) and contaminants (As) in food. For example, the European Commission Regulation 2023/915 set As limits in rice at 0.1 ppm; ICP-OES achieves this with 95% recovery rates.

Irreplaceability Application of ICP-MS:

Ultra-trace Analysis:

ICP-MS’s exceptional sensitivity makes it indispensable for analyzing ultra-trace elements in various matrices, including environmental samples, biological tissues, and high-purity materials.

It is crucial for detecting extremely low concentrations of toxic elements like mercury and arsenic, where even minute amounts can pose health risks. A 2025 Lancet study used ICP-MS to measure blood Pb levels in children (0.05 ppb detection limit), identifying correlations with cognitive impairment.

Analyzing ultra pure materials for semi conductor creation requires the sensitivity that only ICP-MS can provide.

Isotope Research:

ICP-MS’s ability to determine isotope ratios provides valuable insights in fields like geochronology, environmental tracing, and nuclear forensics.

Geologists employ ICP-MS for uranium-lead dating (²³⁸U/²⁰⁶Pb ratios) with 0.05% precision. In forensics, Pu isotope ratios traced radioactive contamination in a 2024 nuclear incident to a specific reactor.

ICP-MS is indispensable for ultra-trace quantification and isotopic studies, despite higher operational complexity.

How to Choose These Equipment?

The choice between ICP-OES/AES and ICP-MS hinges on the specific analytical requirements.

- High-throughput, multi-element analysis? ICP-OES is preferred.

- Trace-level sensitivity required? ICP-MS is the best choice.

- Working with complex sample matrices? ICP-OES offers better robustness.

Cost-benefit Analysis:

Machine Cost: ICP-OES/AES is more affordable ($20,000-$50,000) compared to ICP-MS ($60,000-$200,000).

Maintenance Cost: ICP-MS requires frequent maintenance due to its complex ion optics and vacuum system, increasing operational expenses.

Consumables Cost: ICP-MS needs high-purity argon and frequent replacement of cones and lenses, making its running costs higher than ICP-OES.

Each ICP technique has unique advantages and applications. ICP-OES is ideal for high-throughput analysis in industrial and environmental sectors, while ICP-MS excels in ultra-trace element and isotope studies. Choosing the right method depends on analytical needs, sensitivity requirements, and cost considerations. By understanding these factors, laboratories can make informed decisions to optimize their elemental analysis capabilities.

2.jpg)