Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES) both are two powerful techniques used for the detection and quantification of heavy metals. While ICP-MS and ICP-OES share similar plasma sources, their detection sensitivities differ significantly. Understanding the strengths and limitations of each technique is crucial when selecting the appropriate method for heavy metal analysis.

Overview of ICP-MS and ICP-OES

ICP-MS utilizes a plasma source to ionize the sample and subsequently measures the mass-to-charge ratio of the ions generated. This technique is capable of detecting trace elements at ultra-low concentrations, typically down to parts per trillion (ppt) levels. The mass spectrometer in ICP-MS provides high sensitivity and specificity, making it suitable for detecting very low concentrations of heavy metals even in complex matrices.

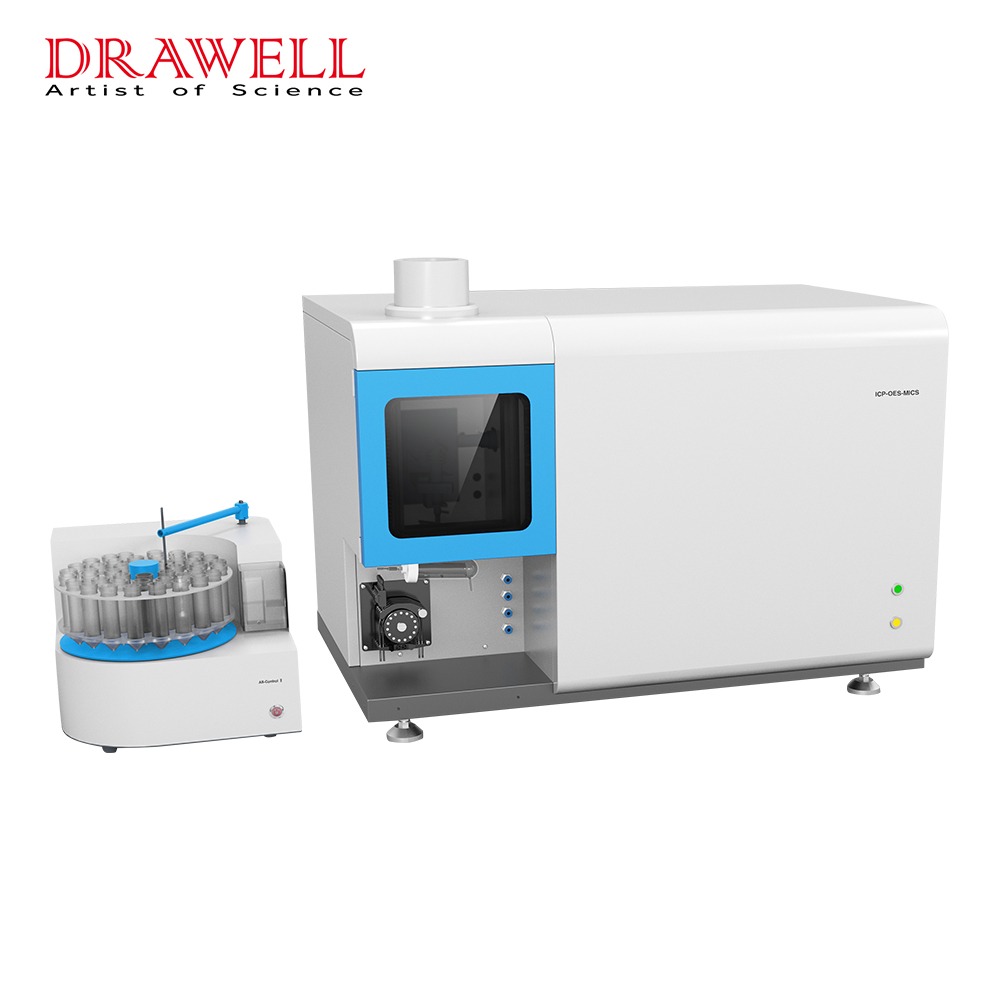

ICP-OES, on the other hand, also uses a plasma source to atomize the sample, but it measures the intensity of light emitted by excited atoms and ions at characteristic wavelengths. This technique is effective for detecting metals and other elements at parts per million (ppm) or parts per billion (ppb) levels, making it a robust method for many applications where trace-level detection is not required.

Detection Sensitivity Comparison between ICP-MS and ICP-OES

1. Lower Detection Limits (LDLs)

ICP-MS is known for its unparalleled detection sensitivity, often achieving limits as low as 0.001 ppb (1 ppt) for many heavy metals. This makes it particularly effective for detecting trace elements such as lead, mercury, arsenic, and cadmium, which are hazardous even at very low concentrations.

ICP-OES, while still sensitive, typically has higher detection limits. It can accurately detect elements in the ppb range, but for ultra-trace analysis, ICP-MS is generally the better choice. ICP-OES works well for applications where concentrations are not extremely low, such as in industrial processes or geochemical samples with higher element concentrations.

2. Matrix Effects

ICP-MS is more sensitive to interference from matrix elements, particularly in complex samples like those containing high salt concentrations or organic compounds. Such interferences can affect the ionization process, resulting in inaccurate readings. To mitigate this, ICP-MS systems often employ collision or reaction cells to reduce matrix effects, although this adds to the complexity of the analysis.

ICP-OES tends to be more tolerant of matrix effects, particularly when dealing with high-concentration samples. It can handle a wider variety of sample types without requiring as much correction for interferences, making it a robust tool for routine applications.

3. Dynamic Range

ICP-OES generally has a wider dynamic range compared to ICP-MS. This allows it to handle samples with both high and low concentrations of analytes in a single run without requiring extensive sample dilution. This is particularly useful in applications where both major and trace elements need to be quantified simultaneously.

ICP-MS, while highly sensitive, has a more limited dynamic range, especially for elements that occur in high concentrations. High-concentration samples often require dilution before analysis to avoid detector saturation, which can complicate the workflow.

4. Interferences

ICP-MS can suffer from isobaric interferences (where two ions have the same mass-to-charge ratio) and polyatomic interferences (where multiple atoms combine to form interfering species). These interferences can affect the accuracy of measurements, especially for certain heavy metals like iron and arsenic. Advanced ICP-MS systems incorporate methods to address these challenges, but this adds to the cost and operational complexity.

ICP-OES, on the other hand, faces fewer interferences from isotopes or polyatomic species. However, spectral interferences, where emission lines of different elements overlap, can occur, especially when analyzing elements with closely spaced emission lines.

Application-specific Considerations of ICP-MS and ICP-OES

This chart compares ICP-MS and ICP-OES specifically in terms of their detection sensitivity for heavy metals in various applications.

| Application | ICP-MS (Detection Sensitivity) | ICP-OES (Detection Sensitivity) |

| Environmental Monitoring | – Ultra-trace sensitivity (ppt level) for toxic metals | – Suitable for detecting metals in ppb-ppm range |

| – Ideal for arsenic, lead, mercury in trace amounts | – Effective for routine environmental screening | |

| Geochemical Analysis | – Detects trace and ultra-trace metals in complex samples | – Good for bulk metal analysis with lower sensitivity needs |

| – Essential for rare or low-concentration elements | – Handles high concentrations of elements like iron, calcium | |

| Industrial Quality Control | – High sensitivity for detecting trace impurities | – Sufficient for detecting higher concentration impurities |

| – Detects low-level heavy metal contaminants | – Adequate for broader elemental analysis | |

| Food and Pharmaceutical Safety | – Critical for detecting trace toxic metals like cadmium | – Suitable for general metal presence analysis at ppb levels |

| – Ultra-sensitive, ensuring compliance with strict regulations | – Less sensitive but useful for broader screening | |

| Water Quality Testing | – Superior for trace detection of contaminants (e.g., lead, mercury) | – Can handle higher concentrations but less sensitive at ultra-trace levels |

| Cost and Accessibility | – Higher cost due to ultra-sensitive detection capability | – More affordable for routine heavy metal testing |

| Complexity and Maintenance | – Requires expertise and advanced maintenance for ultra-trace detection | – Easier to operate with lower maintenance requirements |

Overall, ICP-MS offers superior detection sensitivity, especially for ultra-trace heavy metal analysis, making it the preferred choice for applications where extremely low detection limits are critical. On the other hand, ICP-OES is more suitable for routine analyses, handling higher concentrations and complex matrices with ease. The choice between the two techniques depends on the specific analytical requirements, including the concentration range of interest, sample complexity, and budget constraints. Both methods are highly effective, and when used together, they can provide a comprehensive solution for heavy metal analysis across a wide range of industries.

2.jpg)