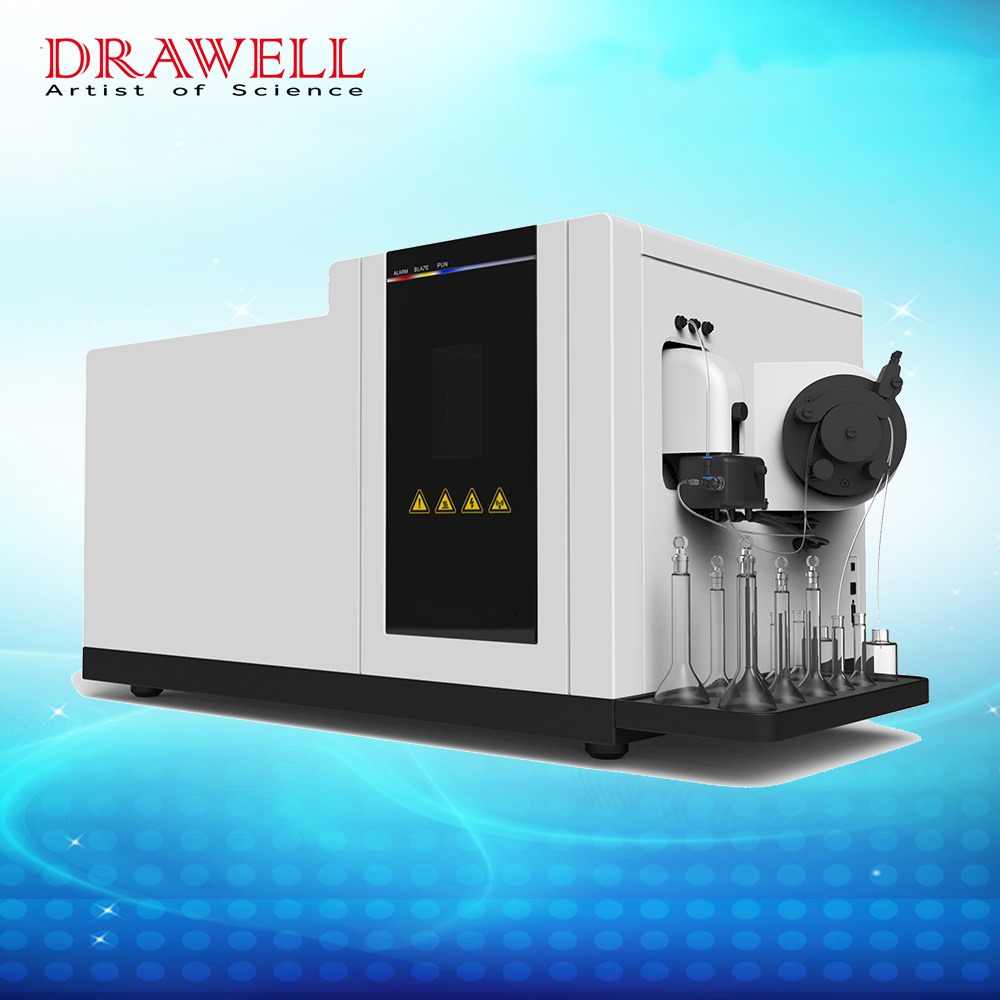

ICP-MS DW-SUPEC7000 Inductively Coupled Plasma Mass Spectrometer

As a new generation of heavy metal analysis system, the inductively coupled plasma mass spectrometer can be combined with LC, automatic sampler, automatic graphite digestion system and other connected technologies.

The system is widely used in water quality, soil, atmospheric particulate matter, solid waste, food, animals and plants, food contact materials, cosmetics, semiconductors, high purity materials, minerals, petrochemical, industrial products, textile and other fields, and meets the requirements of relevant national standards for analysis methods.

Specifications of ICP-MS DW-SUPEC7000 Inductively Coupled Plasma Mass Spectrometer

| Mass range | 2-260 amu |

| Mass resolution | high resolution and standard resolution, adjustment range 0.3-2.0amu. Continuously adjustable, both modes can be used during one method analysis in order to expand the sample analysis application by change resolution. |

| Linear dynamic range | greater than 9 orders of magnitude. |

| Background stability | defined as the mean of the background signal at 5amu, below 0.5 cps. |

| Short-term stability | 20 min stability RSD <2% |

| Long-term stability | 2-hour stability RSD <3% |

| Sensitivity | under the same instrument conditions, the sensitivity of Li should be above 20 Mcps / ppm, In should be above 180 Mcps / ppm, and U should be above 200 Mcps / ppm.2.12.8 Double charged ions and oxide ions: Ce + + / Ce + below 3%, CeO+/Ce+Less than 3% of this amount of the. |

| Limit of detection | The detection limit of Li should be lower than 2ppt, In, which should be lower than 0.1ppt,The detection limit of U should be lower than 0.1ppt. |

| Abundance Sensitivity | Low mass end: 1 x 10-6; High-quality end: 5 x 10-7。 |

| Stability of the mass axis | <0.05 amu / 24h. |

| Isotope ratio accuracy | < 0.2% (107Ag/109Ag), equipped with isotope ratio measurement capability. |

Features of ICP-MS DW-SUPEC7000 Inductively Coupled Plasma Mass Spectrometer

1. Ion source

- Balanced drive, reduces ion kinetic energy dispersion, reducing secondary ion production, without additional expensive consumables such as shielding ring, can eliminate the secondary arc discharge of the cone mouth, prolong the service life of the cone.

- Provide 500W ultra-low power standby, reduce the argon consumption by more than 50%, and the argon consumption is only 5 L/min.

2. Interface: nickel and platinum. Handle type cone changing system, with interlock protection, to prevent abnormal operation. Simple external cone maintenance, without vacuum leakage can be convenient cone maintenance, and avoid coil damage.(10 sets of cones shall be provided for cone replacement)

3. Extraction lens: The extraction lens can use zero voltage, negative voltage and positive voltage and other extraction modes, unique design, maintenance-free cleaning.

4. Ion transmission system: low background ion transmission design, ion before and after two off-axis, to achieve the effective elimination of interference particles (neutral particles, electrons, photons), without the need to replace the cleaning ion lens.

5. Collision reaction cell: With a new six-pole collision / reaction cell system, the distributed intake system eliminates maximum interference, greatly improves collision efficiency and improves sensitivity.

6. Four level bar mass analyzer: high precision pure Mo material quadrupole, ensure the best mass axis stability, using 2.0 MHz low frequency drive quadrupole, to obtain a wider mass spectrum analysis range and better mass axis stability.

7. Detector: pulse / analog dual-mode discontinuous tap pole detector can complete scanning and selection analysis (qualitative and quantitative analysis) during the first injection process, and can realize automatic switching between analog and pulse modes.

8. Plasma visual system: it has the function of real-time plasma observation with electromagnetic shielding. It can monitor the plasma state in real time through the workstation software, and monitor the state of plasma, cone mouth and central tube in real time to facilitate sample analysis, maintenance and confirmation.

9. Silent cover: Silent cover can be configured to reduce laboratory noise and improve the laboratory analysis environment.

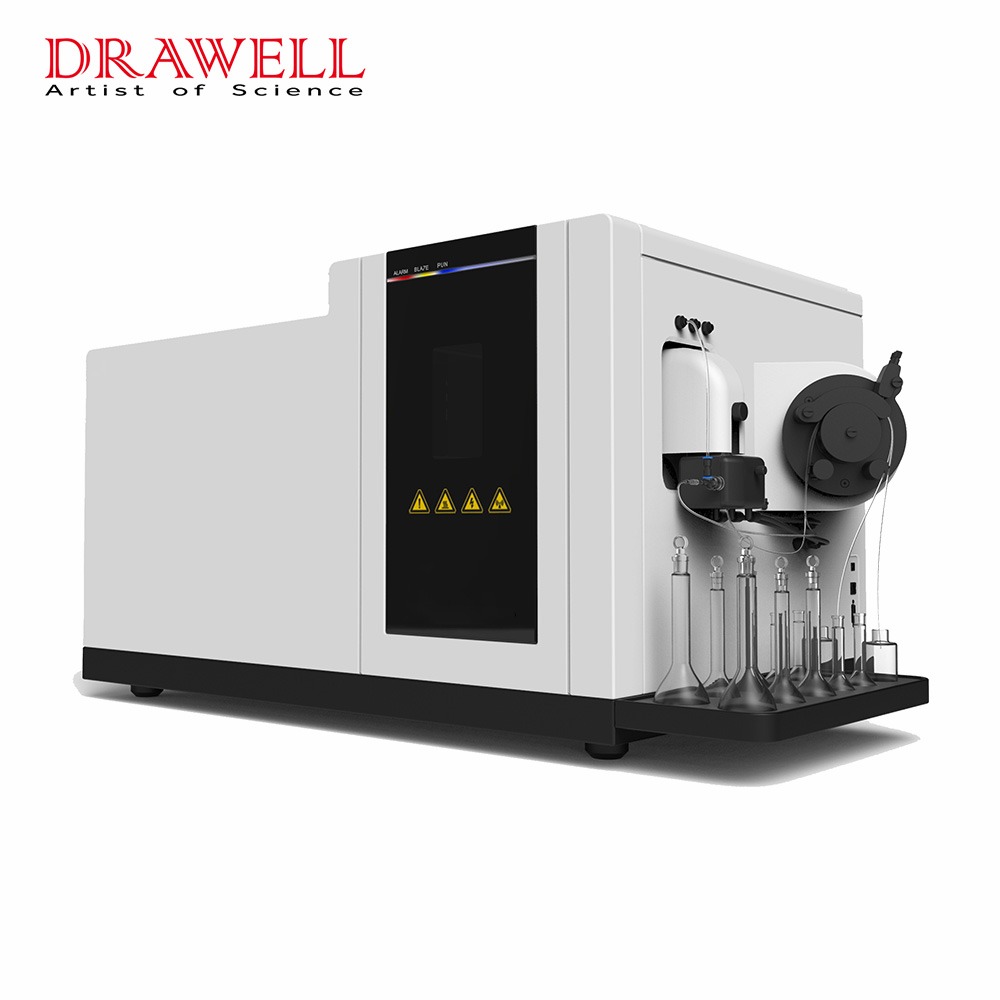

10. Sample injection system

- Provide a variety of atomizers, including efficient quartz concentric atomizer with high salt resistance and PFA microinjection, with high atomization efficiency and hydrofluoric acid injection resistance.

- Small volume inert cyclone atomization chamber, small dead volume, strong corrosion resistance, high aerosol atomization efficiency, low memory effect, standard TEC of refrigeration module, refrigeration temperature <-15℃, improve the continuous working stability of the instrument and organic solvent analysis ability, reduce the oxide yield, improve the stability of the instrument.

- Detachable quartz torch tube with split design, pre-collimated torch tube seat built-in air path connection, easy to operate card into the torch tube design, convenient for daily replacement and maintenance without removing the gas pipe.

- A variety of central tubes are optional, and they are separated from the torch tube. For different applications, the central tubes can be replaced for organic, high salt, high sensitivity and HP acid resistance to facilitate replacement and maintenance.

- High-precision gas mass flowmeter is equipped with standard control of four-way working gas, including atomized gas, auxiliary gas, cooling gas and collision gas. The fifth additional gas can be used as the dilution system.

- Fully automatic on-line gas dilution device can be configured, which can dilute the sample matrix to less than 0.3% before the moment tube, ensure that the interface area and mass spectrum area are not contaminated by high matrix, eliminate the signal inhibition effect caused by high matrix, and have two working modes: preset dilution multiple and manual adjustment of the dilution gas flow. Conventional ICP-MS is resistant to ~0.2% salt tolerance and enables direct determination of> 10% salt content after dilution with argon.

11. Software requirements

- Operating system: well-known brand commercial computer, Microsoft® Windows 10, etc., multi-task, multi-user system software.

- Automatic analysis functions (instrument visualization interface, automatic tuning, automatic diagnosis, customized user report, start and close vacuum, torch position adjustment, plasma parameters \ ion lens voltage optimization, standard \ collision pool, working mode switching, etc.).

- Real time data display and real time report display.

- Other intelligent functions include: dynamic adjustment of injection time and flushing time, user method library management, and QC function can meet the QC requirements of EPA method.

- The ICP-MS operation software can also be installed on a personal computer, and the sample analysis data can be used for offline data processing and generating reports.

- HPLC-ICP-MS interface: the existing HPLC and ICP-MS can control simultaneously with the same computer and the same set of software, to realize online automatic synchronous analysis system, including real-time display, real-time data analysis, spectrum superposition, retention time, peak integration, working curve, automatic injection analysis and other functions.

- Automatic super microwave-ICP-MS interface can be configured with and can use the same computer and the same set of software to simultaneously control the automatic super microwave and ICP-MS, realize online automatic “one key” analysis, including acid, cover, digestion, volume, mixing, ignition, injection, sample, establish standard, report and a series of automatic functions.(Provide the screenshot of the proof of the official website)

- Possess the ability to modify the software source code to meet special needs such as online monitoring

Configuration of ICP-MS DW-SUPEC7000 Inductively Coupled Plasma Mass Spectrometer

1. Icoupling mass spectrometer host, including:

- Sample cone / intercept cone.

- The RF generator.

- Deflected ion lens.

- The collision reaction pool.

- Full mass flow gas controller.

- The detector.

- Mechanical pump.

- Four-channel peristaltic pump.

- Pressure-reducing valve.

- Rol chamber assembly.

- Quartz concentric atomizer assembly.

- Central pipe assembly of quartz moment tube.

2. The ICP-MS dedicated analysis software and the online help system.

3. Fast injection sample control software module.(Provide proof of software screenshots.)

4. ETV solid injection control software module.(Provide proof of software screenshots.)

5. Control software module of fully automatic super microwave digestion device.(Provide proof of software screenshots.)

6. One set of tuning fluid and internal standard solution.

7. One-year consumables requirements: (not included in the random consumables)

- quartz moment tube 1piece

- Peristtic pump drain tube 1 pack

- Peristtic pump into sample tube 1 pack

- Internal label into the sample tube 1 pack

Other supporting configuration

1. Computer system

I 5-8500,8G, 1TB hard drive, 23-inch HD monitor, dual network card.

2. Cooling of the circulating water system

Refrigeration capacity is 2100W, water tank volume is greater than 2L, and voltage is 220V.

3. The Laser Printer

Black and white laser printer

4. AC parameter voltage regulator

15 KVA, input voltage of 140V-300V, output voltage of 220 V ± 1%.

5. Uninterruptible power supply

10 KVA, one hour delay, high frequency UPS, configured with 12 V 38 AH-16.